Insulated Acoustic Flexible Duct Aluminum Foil Flexible Duct

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Insulated Acoustic Flexible Duct Aluminum Foil Flexible Duct

1.Structure of Insulated Acoustic Flexible Duct Aluminum Foil Flexible Duct:

Flexible air ducts are typically made of flexible plastic over a metal wire coil to shape a tube. And they have a variety of configurations. Flexible ducts are very convenient for attaching air outlets to the rigid ductwork. It is commonly attached with long zip ties or metal band claps. Besides, flexible ducts can tolerate moderate negative pressures.

2.Main Features of Insulated Acoustic Flexible Duct Aluminum Foil Flexible Duct:

-Applied in air conditioning/ventilation systems

-Tear and puncture resistant

-Corrosion resistant

-High flexibility

-Convenient installation

-No toxic gas emission

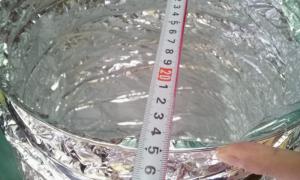

3. Insulated Acoustic Flexible Duct Aluminum Foil Flexible Duct Images

4. Insulated Acoustic Flexible Duct Aluminum Foil Flexible Duct Specification

Insulated Flexible Duct

Structure: 1 layer of Aluminum Foil+1 layer PET film+insulated glass wool

Outer jacket: 1 layer of Aluminum Foil

Glass Wool Density: 16kg/m3; Thickness: 25mm

Insulated Acoustic Flexible Duct

Structure: 1 layer of Aluminum Foil +1 layer PET film+ insulated glass wool

Outer jacket: 1 layer of Aluminum Foil + 1 layer of PET film

Glass Wool Density: 32kg/m3; Thickness: 25mm

Specification

Type 1

Material | Aluminum foil |

Structure | Inner pipe is made of aluminum foil and inside spiral structure is hold by high tensile steel wire. |

Application | Suitable for medium-low air speed |

Technical Parameter

Size | 4”-16” |

Standard Length | 10m |

Maximum Air Speed | 20m/s |

Maximum Heat Resistance | -20℃-150℃ |

Maximum Pressure | 250mmWG |

Type 2

Material | Aluminum foil 25mm thickness ,16kg/m3 glass wool. |

Structure | Inner pipe is made of aluminum foil and inside spiral structure is hold by high tensile steel wire. Insulating layer is covered by 25mm thickness ,16kg/m3 glass wool. Outside layer: Reinforced aluminum foil; Inside layer: Glass fiber mesh |

Application | Suitable for medium-low air speed and low temperature difference. |

Technical Parameter

Size | 4”-5”, 6”-12”, 14”-16” |

Standard Length | 7m, 10m |

Maximum Air Speed | 20m/s |

Maximum Heat Resistance | -20℃-150℃ |

Maximum Pressure | 250mmWG |

Type 3

Material | ·Aluminum foil · 25mm thickness ,24kg/m3 glass wool. |

Structure | · Inner pipe is made of aluminum foil and inside spiral structure is hold by high tensile steel wire. · Insulating layer is covered by 25mm thickness ,24kg/m3 glass wool. · Outside layer: Reinforced aluminum foil; Inside layer: Glass fiber mesh |

Application | Suitable for medium-low air speed and large temperature difference. |

Technical Parameter

Size | 6”-12” |

Standard Length | 7m |

Maximum Air Speed | 20m/s |

Maximum Heat Resistance | -20℃-150℃ |

Maximum Pressure | 250mmWG |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1.How long for the delivery time?

Delivery time: 10-30 days, it depends on the ordered quantity.

2.What’s the usage?

Practicality: suitable for the densely-populated area(such as school, supermarket, office, stadium, theater, factory.),high requirement of the environment area, such as hospital, laboratory, howff, bus, train, broadcasting studio. main usage: 1) Cold, hot water supply facilities for public buildings 2) Food, chemical, electronic industrial pipeline networks such as pipeline networks for transporting all kinds of corrosive liquid 3) Drinking water production system pipeline networks such as pure water and mineral water 4) Air conditioning facility pipeline 5) Compressed gas pipeline networks for industry 6) Pipeline network for swimming pool 7) Pipeline network for solar energy facility 8) Agriculture and garden production Additional information

③How you control the quality?

During the production of fiberglass insulation, material is sampled at a number of locations in the process to maintain quality.

- Q: If I feel the room cool off, one hour hot and open an hour this will be more expensive? More

- But after all, is the master you want to Zhuo good jade is certainly a lot of difficulties, whether it is Longfeng Pei or other subject matter need a lot of effort in addition to the need for technical research also need to continue to learn theoretical knowledge, especially

- Q: Air to water heater host and air conditioning host is not the same

- This test with a small sample length 127mm, width 12.7mm, the maximum thickness of 3.2mm. In the absence of ventilation test chamber. The top of the specimen (6.4 mm place) is clamped with a clamp on the bracket and the longitudinal axis of the specimen is kept vertical. The lower end of the specimen is 9.5mm from the lamp tip and 305mm from the dry absorbent cotton surface. Bring the Bunsen burner and adjust it to produce a blue flame with a height of 19mm. Place the Bunsen Lights flame at the bottom of the sample for 10s, then remove the flame (at least 152mm away from the specimen) and write down the sample. Burning time. If the flame of the sample within 30s after removal of the flame is extinguished, the original lamp must be moved under the specimen again, re-ignite the sample for 10s, and then remove the Bunsen burner again and note the flame burning And flames burning the burning time. If the sample droplets drip, let it fall into the sample under the 305mm cotton, to see whether it ignited cotton. If the absorbent cotton is on fire, the rating should be taken into account. Specific grading indicators are as follows. Test Item 94V-094V-194V-21 Ten-time ignition Total flame burning time Maximum value (S) Individual flame burning time Maximum value (s) Flameless burning time (s) Yes Flame drop No No Allow only short time Burning general UL yellow card on the thickness of the test strip is divided into: 1/8 inch, 1/16 inch, 1/32 inch thickness, that is, 3.2mm, 1.6mm, 0.8mm three grades test.

- Q: Air conditioning ventilation when the sound is a big reason

- No matter, it is best to cut the distance between the material and the roof, like an arbor. Otherwise it is not foam board with it

- Q: Gree air conditioning 50 heating and cooling mechanism heat when the host cooling network is how the matter

- Extruded board of course, can generally use this to do, indoor and outdoor to do almost, most of the outside is done because of saving space inside the room. Recommended: do indoors, because I was doing the external walls, the insulation often do, the wall is not very good for the first time, because you do before the insulation wall itself is the weight of the valve valve closure of the bone shop stall wipes , Benzene board sticky benzene board is not very strong, live well for a few years, bad two or three years there will be signs of shedding, looking twice thinking.

- Q: Do 3cm thick wall insulation how much kilogram of slurry and how many kilograms of polystyrene particles

- From the outside: ① rigid waterproof casing is only composed of steel casing and wing ring, simple structure; ② flexible waterproof casing mainly by: flange casing, seals, flange pressure plate, wing ring, bolts, nuts Composition, complex structure From the waterproof performance up to choose: ① rigid waterproof casing is outside the wing (ring made of steel ring on the steel pipe), installed in the wall (mostly concrete wall), for the general pipe wall, ; ② flexible waterproof casing in addition to the external wing ring, the internal file ring and the like, the flange wire, there are sets of sales, but also their own processing, for the need for shock absorption pipeline, such as and pump connected When the pipe is through the wall In other words, if the wall on both sides of the waterproof performance, it is necessary to use flexible waterproof casing; if only to consider the pipe through the wall, without considering the wall, the wall on both sides of the waterproof performance and displacement of the pipeline deformation You can use rigid waterproof casing

- Q: I added the space 18 degrees opened for 5 hours or not cold, we all know how is it? More

- Common points are all sandwich panels, with a hard protective layer, the difference is the middle of the different materials, such as polystyrene board, polyurethane board. Polystyrene board which is the most common, because the price is cheap, easy to use so the use of more, but if the temperature is more than the requirements of the chicken inertia glycosylation moxibustion slim faint words, polystyrene board is not satisfied , So there is a polyurethane sandwich panels, polyurethane thermal conductivity of less than 0.. in the existing insulation materials, large quantities of processing, be the best. But because of its process is more complex, and the cost is relatively high, so with less, the common combination of cold storage and the like, I believe that with the economic and technological development, polyurethane sandwich board market share will be more and more High

- Q: What is the whole heat exchange fresh air ventilator?

- Depends on the main control panel is not cold and warm, single cold common motherboard. Only a generic motherboard can be changed. In the single cold air-conditioning on the outdoor machine to install the appropriate specifications of the four-way valve, adjust the amount of refrigerant to the appropriate level can be.

- Q: External wall insulation method of operation There are several combinations of materials

- 30-150 per square meter has, mainly to see the material, thickness and so on

- Q: The installation method of ordinary air conditioner. The more detailed the better. Please thank you all

- The basic operation of the same, but the different requirements of different professional, or to determine the direction of good, and then hands.

- Q: In the design, the building structure and the hydropower are generally designed by the Architectural Design Institute. The air conditioning ventilation is based on the design of the room. Or first air conditioning ventilation? More

- Aluminum alloy metal shell better than the plastic shell; we all know that most of the market is now charging the lithium battery, lithium battery is the only drawback is the possibility of a long time with the explosion, so the use of aluminum Alloy shell, much better than steel; polymer battery is good, but the price is expensive,

Send your message to us

Insulated Acoustic Flexible Duct Aluminum Foil Flexible Duct

- Loading Port:

- Shekou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords