1060 Aluminum Coil Wholesale - Household Cooking Baking Catering Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

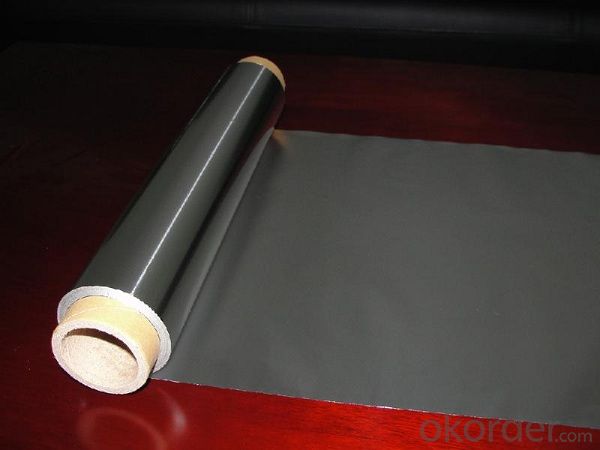

Household Cooking Baking Catering Aluminium Foil

l Product Description

Features

1.The luster is luminous |

2.Non-toxic,odorless, impermeable |

3.withstand high heat and extreme cold |

4.Minimize cleanup and ensure food fresh |

5.Foil sheet conveniently dispensed one at a time |

Application of aluminum foil

Applicable fields | Cooking, hair salon, gift packing, industrial insulation, tin foil, electronic products isolated signals |

Applicable places | Household, Catering, hotel, restaurant,airline, factory etc. |

Detailed application in cooking | Lining baking pans, freezing meat, lining cookie sheet, lining charcoal grill, roasting turkey etc. |

Size of alumninum foil

| length | 300m |

| width | 450mm |

| thickness | 17mic |

Hot sizes of aluminum foil

Length | 30m, 45m, 60m, 305m, 600m, customized. |

Width | 30cm, 38cm, 45cm, |

Thickness | 0.015mm-0.017mm |

l Packaging & Delivery

Packaging detail: one roll per box ,four boxes per carton or as customized

Delivery detail: about 25 days from received original L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

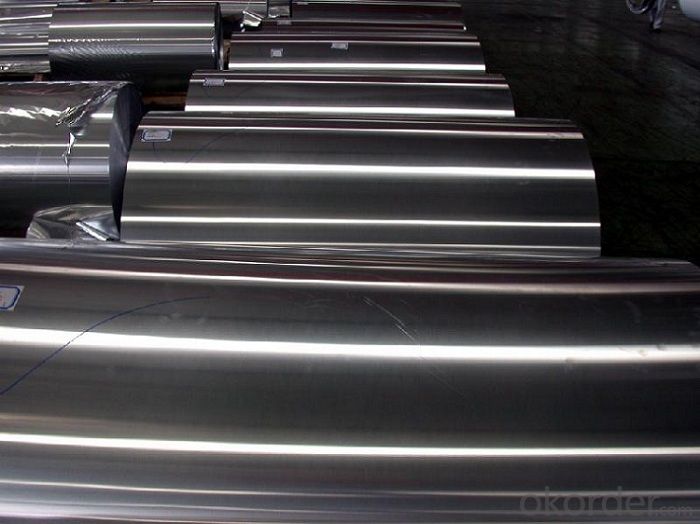

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: What substances are used to make aluminum coils?

- <p>Aluminum coils are made from aluminum, a lightweight and malleable metal with the chemical symbol Al. They are typically produced from high-purity aluminum or aluminum alloys, which may include small amounts of other elements to enhance specific properties such as strength, durability, or resistance to corrosion. Pure aluminum is soft and lacks strength, so alloys are often used to improve these characteristics for various applications.</p>

- Q: How do aluminum coils contribute to the thermal conductivity of products?

- Aluminum coils contribute to the thermal conductivity of products by efficiently transferring heat. Due to their high thermal conductivity, aluminum coils can quickly absorb and distribute heat, allowing for effective thermal management in various applications such as HVAC systems, refrigeration units, and heat exchangers.

- Q: What is an aluminum coil and what is it used for?

- An aluminum coil is a long, thin, and flat strip of aluminum that is typically rolled up. It is used in various industries, including construction, automotive, and electrical, due to its excellent properties such as lightweight, corrosion resistance, and conductivity. Aluminum coils are commonly used for manufacturing various products like roofing, gutters, cans, heat exchangers, and electrical wiring, among others.

- Q: How do aluminum coils perform in cryogenic environments?

- Due to their low thermal expansion coefficient and high thermal conductivity, aluminum coils have excellent performance in cryogenic environments. When subjected to extremely low temperatures, aluminum coils display minimal contraction and expansion, making them suitable for cryogenic applications. The coils' low thermal expansion coefficient ensures that they maintain their structural integrity and do not deform or crack when exposed to extreme temperature fluctuations. Moreover, aluminum's high thermal conductivity facilitates efficient heat transfer, enabling the coils to effectively dissipate excess heat and maintain a stable temperature in the cryogenic environment. All in all, aluminum coils are a dependable choice for use in cryogenic environments and can effectively withstand the challenges presented by extremely low temperatures.

- Q: I would like to know because I'm getting a sword with an aluminum sheathe.

- wouldnt advise,it might bend Aluminium is a soft, lightweight metal with appearance ranging from silvery to dull gray, depending on the surface roughness. Aluminium is nontoxic, nonmagnetic, and nonsparking. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa.[1] Aluminium has about one-third the density and stiffness of steel. It is ductile, and easily machined, cast, and extruded.

- Q: This question asks for a comparison of the benefits and drawbacks associated with using aluminum coil.

- <p>Aluminum coil offers several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent thermal and electrical conductivity. It is also cost-effective and easy to form, making it ideal for various applications like construction, automotive, and electrical industries. However, it has some disadvantages, including lower strength compared to steel, potential for galvanic corrosion when in contact with dissimilar metals, and a higher likelihood of denting or denting. Additionally, aluminum's recycling process can be energy-intensive, which may impact its environmental sustainability.</p>

- Q: Is aluminum silicate roll felt the same as aluminum silicate acupuncture blanket?

- No, the unit weight of aluminum silicate fiber felt is greater than that of aluminum silicate acupuncture blanket. Both are thermal insulation and fire-proof material and have the same function.

- Q: So on friday we mixed crystaline copper chloride stuffs with water to make a clear blue solution. We then put some aluminum into the solution. The solution began to heat up and there was a redish brown precipitate at the end. What caused the heat? What was boiling? How does the mass of the original aluminum and original copper chloride crystaline stuff compare with the mass of the red/brown power stuff (we strained the liquid out), and the mass of the dried up blue stuff?

- You're looking at a redox reaction. During this process, the copper ions in solution are reduced to form copper metal (visible as dust) and the aluminum metal is oxidized to form aluminum ions. This process is exothermic due to the relative electron affinities and the positions on the activity sequence such that copper has a greater affinity for electrons and is a stronger oxidizing agent. I think aluminum forms a 3+ ion and copper forms either a 1+ or a 2+ ion. Copper's molecular weight is 63g/mol and aluminums weight is 27 g/mol. You would see the weight decrease because aluminum weighs less than Copper and is replaced less frequently due to the higher charge when you figure out the ionics. Nothing was boiling.

- Q: Can aluminum coils be used in high-humidity environments?

- Yes, aluminum coils can be used in high-humidity environments. Aluminum is a corrosion-resistant metal, and when properly protected with coatings or finishes, it can withstand high levels of humidity without rusting or deteriorating.

- Q: How are aluminum coils manufactured to specific dimensions?

- Precision engineering and cutting-edge technology are utilized to manufacture aluminum coils with specific dimensions. The process commences with the selection of high-quality aluminum ingots, which are subsequently melted and cast into long, flat strips. Upon achieving the form of flat strips, the aluminum undergoes a sequence of rolling operations. The strips pass through a rolling mill, gradually decreasing in thickness and elongating in length. This rolling process is instrumental in attaining the desired dimensions and thickness for the coils. Following the initial rolling, the strips undergo annealing, a process involving heating the aluminum to a specific temperature and then cooling it slowly. This procedure enhances the ductility and reduces internal stresses in the metal, making it more manageable for subsequent manufacturing steps. The subsequent step is slitting, which involves cutting the wide strip into narrower strips of the desired width. High-precision slitting machines ensure accurate and consistent dimensions for each coil. Additionally, edge trimming is performed during the slitting process to eliminate irregularities and ensure straight edges. Once the narrower strips are obtained, specialized machines are utilized to coil them. These machines carefully wind the strips into coils of the desired size and shape, ensuring secure and tight winding. To further enhance dimensional accuracy, the coils may undergo a final leveling process. This process entails passing the coils through a machine that applies pressure to flatten any irregularities or distortions in the metal, ensuring a uniform and consistent thickness. In summary, the manufacturing of aluminum coils with specific dimensions necessitates a combination of precision rolling, slitting, coiling, and leveling processes. These processes, in conjunction with advanced machinery and quality control measures, guarantee that the final product meets the precise specifications required by the customer.

Send your message to us

1060 Aluminum Coil Wholesale - Household Cooking Baking Catering Aluminium Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords