1060 Aluminum Coils Wholesale - Aluminum Coil 5754 8011 1050 1060 for Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

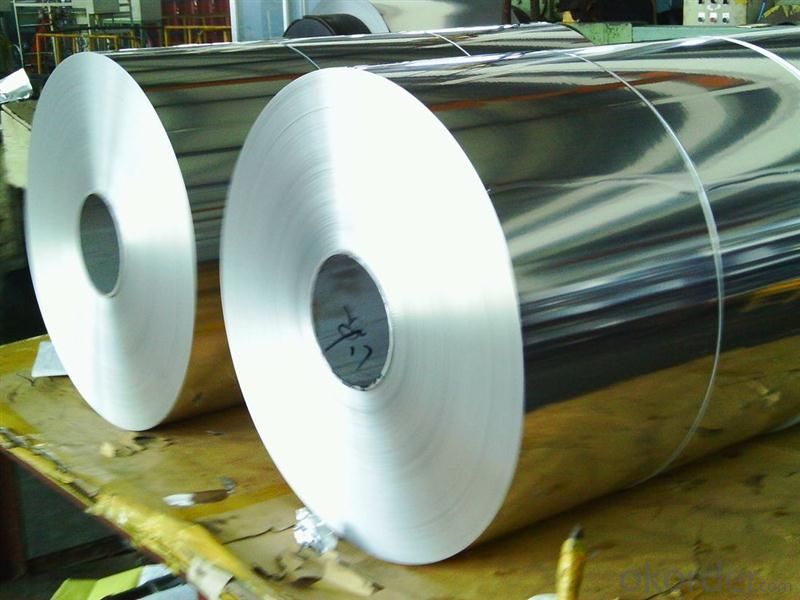

Aluminum Coil 5754 8011 1050 1060 Aluminum Coil For Cans

Applications:

Aluminum foil roll is widely used in construction,decoration,hardware,

electric appliances,machinery and other industrial and civil purposes,

such as electronic capacitor,composite cooker,rice cooker,refrigerator,

computer casting,telecommunication,equipment,lamp shade,air conditioner,

cosmetics cover and so on.

Or it can be made as customers’ requirement.

Specifications

color aluminum coil

1000 series 1100 10160 1200

surface could be: Brushed, drawing, embossed, printing

color: red,

color aluminum coil

.Alloy type: 1050/1060/1100/1350

2.Temper: H16, H18, H22, H24

3.Thickness range: 0.1mm-4mm

4.Width range: 25mm-1600mm

5.Surface:finish: bright & smooth surface, without flow lines, slight oiled to avoid white rusting.

6.Quality material:totally free from such defefects as roll marks, edge damager, camber, white rust, oil patches, holes, break lines,

color aluminum coil

Name |

color aluminum coil |

Alloy or not | yes |

Alloy | 1100H16/18, 3003H24,3003H26,3005H26,8011,3004,3105,5005,etc. |

Thickness | 0.1-4mm |

Width | ≤1600mm |

MOQ | 5T |

Coating finish | Brushed, drawing, embossed, printing |

Color | As to code RAL |

Surface | Embossed,Mill Finish,Coated,Brushed |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | PVDF27 ~35micron |

Polyester18~27micron(EN ISO-2360:1995) | |

Coating hardness | 2H |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

MEK resistance | 100 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

- Q: What are the different grades of aluminum used in coil manufacturing?

- There are several different grades of aluminum used in coil manufacturing, each with its own unique properties and applications. The most commonly used grades include 1100, 3003, 5052, and 6061. - Grade 1100 is a commercially pure aluminum with excellent corrosion resistance and good formability. It is often used in chemical equipment, heat exchangers, and food handling equipment. - Grade 3003 is a non-heat treatable alloy with good corrosion resistance and moderate strength. It is commonly used in cooking utensils, roofing, and general sheet metal work. - Grade 5052 is a high-strength alloy with good formability and excellent corrosion resistance. It is frequently used in marine applications, such as boat hulls and components, as well as in automotive parts and appliances. - Grade 6061 is a heat treatable alloy with excellent strength and good machinability. It is commonly used in structural applications, such as aircraft parts, bike frames, and automotive components. These grades of aluminum offer a range of properties and characteristics, allowing manufacturers to choose the most suitable grade for their specific requirements in coil manufacturing.

- Q: What are the different types of end conditions for aluminum coils?

- The different types of end conditions for aluminum coils include plain end, slit end, trimmed end, and sheared end.

- Q: Are aluminum coils suitable for electrical transformers?

- Yes, aluminum coils are suitable for electrical transformers. They have several advantages, including lower cost, lighter weight, and better thermal conductivity compared to copper coils. Additionally, aluminum coils have been widely used in power transformers, demonstrating their suitability for this application.

- Q: Why the end of the aluminum coil will have a yellow spot?

- The reason may be that the manufacturer is not cleaned, and must be carefully cleaned before coating, or there may be paint fall off phenomenon.

- Q: What is the typical fatigue strength of aluminum coils?

- The typical fatigue strength of aluminum coils can vary depending on various factors such as the alloy composition, heat treatment, manufacturing process, and the specific application. However, aluminum is generally known for its relatively low fatigue strength compared to other metals, such as steel. Aluminum coils typically exhibit a fatigue strength that ranges between 30% to 50% of their ultimate tensile strength (UTS). This means that the fatigue limit or endurance limit of aluminum coils is usually below half of their maximum strength. It is important to note that aluminum's fatigue strength can also be influenced by other factors, including the presence of surface defects, stress concentrations, and environmental conditions such as temperature and humidity. These factors can further reduce the fatigue strength of aluminum coils. Therefore, when designing and using aluminum coils in applications where fatigue is a concern, it is crucial to consider the specific alloy and processing conditions, as well as implementing appropriate design practices and maintenance procedures to mitigate the risk of fatigue failure.

- Q: How heavy and long is the aluminum rolling on average?

- The aluminum density is 2.7, and the average weight of molded aluminum coil is within 3.5 tons. But that depends on the molded width and thickness. The wider and thicker it is , the shorter it is.

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: What is the thickness tolerance of aluminum coils?

- The thickness tolerance of aluminum coils can vary depending on the specific manufacturing process and industry standards, but it is typically within a range of +/- 0.005 to 0.010 inches.

- Q: Can aluminum coils be used for roofing?

- Certainly, roofing can be done using aluminum coils. Aluminum is widely regarded as a top preference for roofing materials because of its sturdy composition, lightweight properties, and exceptional resistance to corrosion. In a wide range of roofing applications, including residential, commercial, and industrial structures, aluminum roofing coils are frequently employed. They offer exceptional safeguarding against severe weather conditions like intense rainfall, snowfall, and powerful winds. Furthermore, aluminum coils possess energy-efficient attributes as they possess the ability to reflect solar heat, thereby aiding in preserving a cool indoor environment and reducing energy expenditures. All in all, aluminum coils present a dependable and enduring roofing solution.

- Q: Are aluminum coils easy to bend and shape?

- Yes, aluminum coils are relatively easy to bend and shape. Aluminum is a malleable metal, which means it can be easily deformed under compression without breaking. This property makes it highly suitable for shaping and forming into various shapes and sizes. Additionally, aluminum coils can be manipulated using different techniques such as rolling, bending, or pressing, allowing for a wide range of applications in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping aluminum coils may also depend on the specific alloy and thickness of the coil. Thicker coils may require more force and specialized equipment for shaping, while certain alloys may have different levels of malleability. Overall, aluminum coils offer a versatile and relatively easy-to-work-with material for bending and shaping purposes.

Send your message to us

1060 Aluminum Coils Wholesale - Aluminum Coil 5754 8011 1050 1060 for Cans

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords