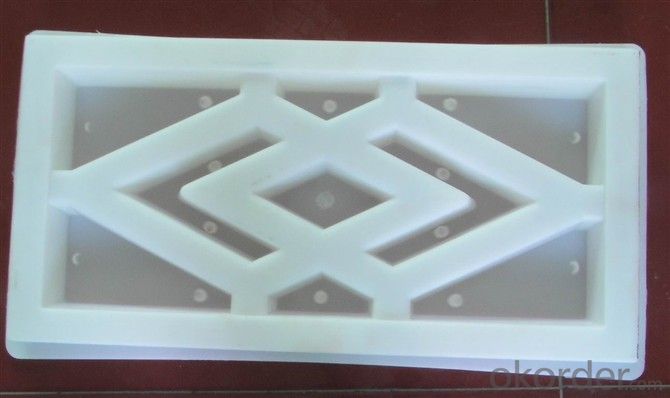

Hot selling concrete brick pavers paving mould stones plastic molds

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

pavers paving mould kerb stones plastic molds

1,easy to operate

2,smooth surface, high hardness

3,durable,3 years warranty

pavers paving mould kerb stones plastic molds

We are a prominent manufacturer, exporter and supplier of PVC/Plastic/Rubber moulds (25/35/60mm) on street color pavers.

Curbstone mold is used to produce precast concrete curbstone. The process is to fill the mold with concrete, and then release the mold from the concrete after it is solidified.

Our plastic Curbstone mold is made of PP (polypropylene) material injection, with best quality and longer lifespan. Our curbstone mold is popular for its dimensional stability and robust construction.The products are used to areas along roadsides ways, platforms, walkways retaining edges and peripherals to beautify the garden. The range is available in standard shapes and beveled.

The special benefits of the PP Curbstone mold:

1, easy to operate, saving time and effort

2, smooth surface, high strength

3, Perfect dimensional stability and robust construction

4, low cost, high return, the device is simple, quick operation, reliable quality

- Q: Can olive nets be used on olive trees grown in humid regions?

- Yes, olive nets can be used on olive trees grown in humid regions. Olive nets are commonly used to protect the olive fruit from birds and other pests, regardless of the region's humidity.

- Q: Can olive nets be used in combination with pruning tools and equipment?

- Yes, olive nets can be used in combination with pruning tools and equipment. Olive nets are typically used for harvesting olives, but they can also be helpful during the pruning process. By placing the net under the tree, it can catch any branches or leaves that are pruned off, making clean-up easier. Additionally, using olive nets can help protect the ground from falling debris and prevent any potential damage to the surrounding area or other plants.

- Q: Can olive nets be used for other types of nuts?

- No, olive nets are specifically designed for harvesting olives and may not be suitable for other types of nuts due to differences in size, weight, and harvesting methods.

- Q: Do olive nets come with a warranty?

- Yes, olive nets typically come with a warranty.

- Q: What is the average size of an olive net?

- The average size of an olive net typically ranges between 10 to 20 feet in width and 30 to 40 feet in length.

- Q: Can olive nets be used for olive tree pollination management?

- No, olive nets cannot be used for olive tree pollination management. Olive nets are primarily used to protect the olives from birds and insects, but they do not play a role in pollination. Pollination in olive trees is mainly done by wind and does not require intervention from nets.

- Q: EVA plastic products poisonous?

- EVA plastic products are non-toxic.Ethylene vinyl acetate copolymer, referred to as EVA. Ethylene vinyl acetate (VA) content in 5%-40%, and polyethylene (PE) compared to EVA due to the molecular chain of the vinyl acetate monomer, thereby reducing the high crystallinity, improved toughness, impact resistance, filler compatibility and heat sealing performance, is widely used in foam material, functional films, packaging mold, hot melt adhesive, wire and cable and toys and other fields.

- Q: Can olive nets be used for other fruits or crops?

- No, olive nets are specifically designed for harvesting olives and may not be suitable for other fruits or crops due to differences in their size, shape, and harvesting methods.

- Q: How do olive nets affect the overall antioxidant content of the olives?

- Olive nets have no direct impact on the overall antioxidant content of olives. The antioxidant content of olives is primarily determined by factors such as olive variety, growing conditions, and processing methods. Olive nets are mainly used to protect the olives from pests and birds during the ripening period, ensuring a higher yield and quality of olives, but they do not affect the antioxidant levels.

- Q: Can olive nets be used for other types of crops?

- Yes, olive nets can be used for other types of crops. Olive nets are commonly used for harvesting olives, but they can also be used for crops such as cherries, almonds, and other tree fruits. The nets serve the purpose of catching the fallen fruits, making it easier to collect and minimize damage.

Send your message to us

Hot selling concrete brick pavers paving mould stones plastic molds

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords