Hot Rolled Steel I-Beam in European Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

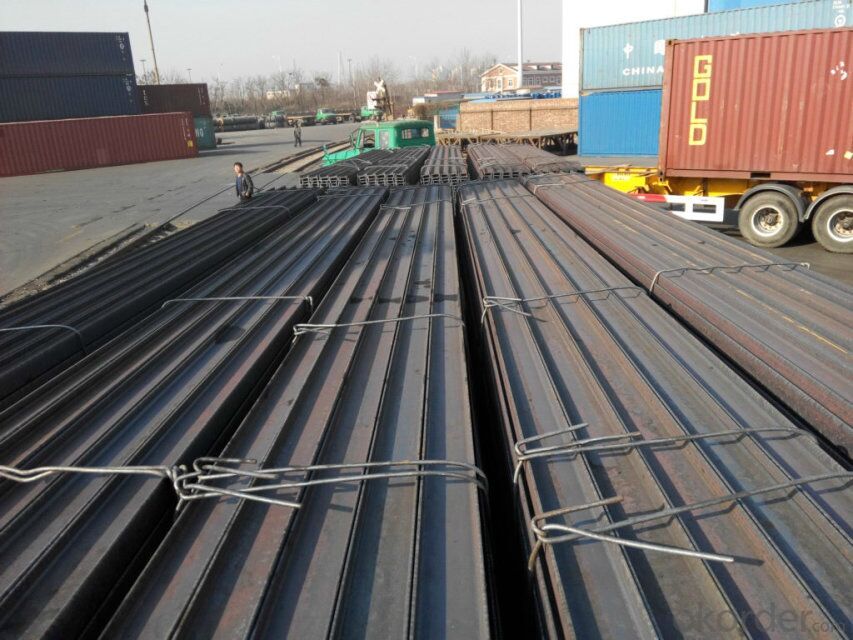

OKorder is offering high quality Hot Rolled Steel I-Beams at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beams are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

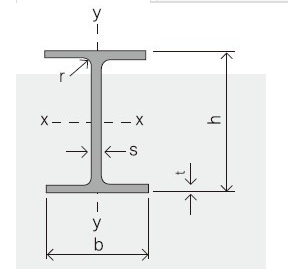

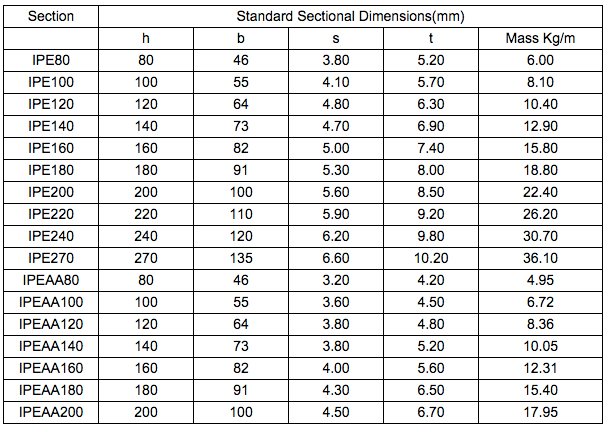

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: The products are invoicing on theoritical weight or on actual weight?

A2: We can do it in both manners, according to the customers' request.

Q3:What's your payment terms ?

A3:Mostly,we collect the money by T/T and LC at sight . We also accept time LC at 90/120 days sigh

.

Images:

- Q: How do steel I-beams perform in areas with high levels of seismic activity?

- Steel I-beams are well-suited for areas with high levels of seismic activity due to their superior strength and flexibility. These beams have excellent resistance to lateral forces and can withstand the shaking and vibrations caused by earthquakes. Their robust construction and ability to dissipate energy make them a reliable choice for structural support, ensuring the safety and stability of buildings in seismic-prone regions.

- Q: What are the different types of steel I-beam profiles?

- In construction and engineering projects, a variety of steel I-beam profiles are commonly utilized. Some of the frequently encountered profiles are as follows: 1. W shape: This particular I-beam profile is widely employed due to its wide flanges and straight web. It offers exceptional strength and stability, making it suitable for a broad range of applications. 2. S shape: The S shape I-beam exhibits tapered flanges and a thinner web in comparison to the W shape. It is often employed in scenarios where lighter weight and flexibility are necessary, such as architectural and aesthetic applications. 3. HP shape: The HP shape I-beam, standing for "H-pile," is primarily used in deep foundation applications. Its distinguishing features include wide flanges and a thick web, providing remarkable load-bearing capacity in situations where high strength and stability are critical. 4. M shape: The M shape I-beam, also referred to as a "miscellaneous" shape, is less commonly encountered and typically utilized for specialized applications. It possesses unequal flanges and a thinner web, rendering it suitable for unique structural requirements. 5. L shape: The L shape I-beam, also known as angle iron, is characterized by its 90-degree angle and is commonly employed in smaller-scale structural applications, such as framing and support brackets. These examples represent a mere fraction of the diverse array of steel I-beam profiles that are available. The choice of profile depends on the specific project requirements, encompassing load-bearing capacity, size limitations, and aesthetic considerations.

- Q: Relationship between H steel and I-beam, C section steel and channel steel

- Difference: 1. Under the condition of the same amount of steel, H steel can do more rigidity and stability than I-beam, and its resistance to bending and bending is better than that of I-beam2, the shape of H steel on the lower flange far wider than I-beam3, the process of H steel can be rolled or welded, steel are rolled

- Q: What are the typical installation methods for steel I-beams?

- The typical installation methods for steel I-beams involve lifting and positioning the beams into place using cranes or hoists, securing them with bolts or welding, and ensuring proper alignment and support through the use of temporary braces or shoring.

- Q: How do you anchor steel I-beams to the foundation?

- To anchor steel I-beams to a foundation, there are several methods commonly used in construction. One common technique is to use anchor bolts or anchor rods. These bolts or rods are typically embedded into the foundation during its construction. The I-beams are then positioned on the foundation, and holes are drilled through the flange plates of the beams to correspond with the anchor bolt locations. The beams are then bolted down to the foundation using nuts and washers, ensuring a secure connection. Another method is the use of epoxy anchors. Epoxy anchors are installed by drilling holes into the foundation and then injecting epoxy resin into the holes. Once the epoxy has cured, steel rods or threaded rods are inserted into the epoxy-filled holes. The I-beams are then secured to these rods using nuts and washers, providing a strong and reliable anchor. In some cases, welding may also be employed to anchor steel I-beams to the foundation. This method involves welding steel plates to the foundation and then welding the I-beams to these plates. Welding provides a permanent and robust connection, but it requires skilled welders and proper welding techniques to ensure structural integrity. The specific method chosen for anchoring steel I-beams to a foundation depends on various factors, such as the load requirements, the foundation type, and the construction regulations applicable in the area. It is crucial to consult with structural engineers and adhere to local building codes to ensure the correct and safe installation of steel I-beams on a foundation.

- Q: Demolition of rural cottage bearing wall, take reinforced beam OK?

- It's more feasible to make reinforced concrete beams. When the bottom formwork, the tie bar, the vertical measuring die, the pouring funnel of the inclined funnel and the concrete are poured, when the concrete strength reaches a certain strength, the funnel concrete is timely removed, the design age is disassembled, the bottom mold is taken, the safety measures are carried out, and the bearing wall is disassembled, and the work is done.To remind you whether or steel reinforced concrete beam, to ask a professional architectural design consulting and design personnel to the scene, not to engage in their own, you live than the new building is complex, cumbersome, safety risk, be careful! Earnestly!

- Q: Can steel I-beams be used in data center or technology facility construction?

- Yes, steel I-beams can be used in data center or technology facility construction. Steel I-beams are commonly used in construction due to their strength and durability, making them suitable for supporting heavy loads and ensuring the structural integrity of the facility. Additionally, steel I-beams can be easily fabricated to meet specific design requirements, making them a viable choice for data center or technology facility construction where precision and stability are crucial.

- Q: Can steel I-beams be used for architectural facades?

- Yes, steel I-beams can certainly be used for architectural facades. Steel I-beams offer several advantages that make them a popular choice for this application. Firstly, steel I-beams are known for their strength and durability. They can withstand heavy loads and provide structural support, making them suitable for large-scale architectural projects. Additionally, steel I-beams are resistant to weathering and corrosion, ensuring their longevity and reducing maintenance requirements. Furthermore, steel I-beams offer design flexibility. They can be fabricated in various sizes and shapes, allowing architects to create unique and visually appealing facades. The sleek and modern look of steel I-beams can add an industrial or contemporary aesthetic to a building's exterior. In terms of installation, steel I-beams are relatively easy to work with. They can be prefabricated off-site, saving time and reducing construction costs. The lightweight nature of the steel also simplifies the installation process. Lastly, steel is a sustainable material choice. It is highly recyclable, reducing the environmental impact of construction projects. Moreover, steel I-beams can be designed to maximize energy efficiency, incorporating insulation and other features to improve a building's overall performance. Overall, steel I-beams offer numerous advantages for architectural facades, including strength, durability, design flexibility, ease of installation, and sustainability. Architects and designers can leverage these benefits to create visually striking and functional building exteriors.

- Q: How do I weld 3 steel plates into I-beam?

- Welded I-beam is generally used to take the load of the beam, most of the plate using low alloy high strength steel. The welding process is to prevent the occurrence of cracks, and the bending deformation of the welded I-beam is sure to happen.

- Q: How do steel I-beams perform in high-wind stadium applications?

- Steel I-beams perform well in high-wind stadium applications due to their strength and stiffness. The structural integrity and load-bearing capacity of I-beams make them capable of withstanding the wind forces exerted on the stadium. Additionally, the design and placement of these beams are carefully engineered to ensure optimal performance and safety, making them a reliable choice for such applications.

Send your message to us

Hot Rolled Steel I-Beam in European Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords