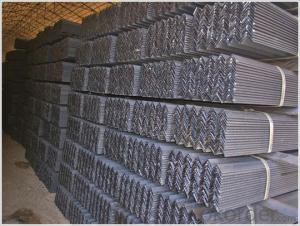

Hot Rolled Steel Angle Bar with High Quality 65*65mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 65*65*5 | 4.907 | 65*65*8 | 7.662 |

| 65*65*6 | 5.841 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customers' request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel angles be used in bridge construction?

- Yes, steel angles can definitely be used in bridge construction. Steel angles, also known as L-shaped structural steel, are commonly used as cross-sectional supports in bridge construction. They are particularly useful for providing stability, strength, and rigidity to bridge structures. Steel angles are versatile and can be used for various bridge components such as beams, trusses, and bracing systems. They are often welded or bolted together to form structural connections, ensuring the integrity and load-carrying capacity of the bridge. Steel angles offer several advantages in bridge construction, including their high strength-to-weight ratio, durability, and resistance to corrosion. Overall, steel angles are a reliable and widely used component in the construction of bridges.

- Q: What is the purpose of using steel angles in construction?

- Steel angles serve various purposes in construction. Their primary function is to offer structural support and stability to different components of a building or structure. Reinforcing corners, edges, and joints, these angles enhance the overall strength and rigidity of the structure. Moreover, steel angles play a crucial role in distributing and transferring loads or forces within the construction. They facilitate the even distribution of weight and stress across various parts of the structure, preventing the formation of weak points. Furthermore, steel angles are highly versatile and can be easily customized and fabricated to meet specific construction requirements. They can be cut, drilled, and welded, seamlessly integrating into a wide range of construction projects. Not only that, but steel angles also exhibit remarkable durability and resistance to corrosion, making them suitable for both indoor and outdoor applications. With the ability to withstand heavy loads and extreme weather conditions, they provide long-lasting support to the structure. In conclusion, the utilization of steel angles in construction aims to enhance structural integrity, provide support and stability, distribute loads, and ensure the longevity of the building or structure.

- Q: How do you protect steel angles from abrasive wear?

- There are several ways to protect steel angles from abrasive wear. One effective method is to apply a protective coating or paint to the steel surface. This coating acts as a barrier between the steel and abrasive materials, preventing direct contact and reducing wear. It is important to choose a coating that is specifically designed for abrasion resistance, such as epoxy or polyurethane coatings. Another method is to use rubber or polyurethane liners. These liners can be attached to the steel angles, providing a cushioning effect and preventing direct contact with abrasive materials. They are commonly used in applications where the steel angles are subjected to high levels of abrasion, such as in mining or bulk material handling. In some cases, it may be necessary to reinforce the steel angles with additional materials. This can be done by welding or bolting on wear plates or inserts made of hardened materials such as chromium carbide overlay or ceramic. These materials have high resistance to abrasion and can significantly extend the lifespan of the steel angles in abrasive environments. Regular maintenance and inspection are also crucial in protecting steel angles from abrasive wear. By regularly inspecting the angles for signs of wear or damage, any issues can be addressed promptly, preventing further deterioration. Additionally, implementing proper lubrication and cleaning practices can help minimize the effects of abrasion on the steel angles. Overall, protecting steel angles from abrasive wear requires a combination of preventive measures, including coatings, liners, reinforcements, and regular maintenance. By implementing these strategies, the lifespan and performance of steel angles can be significantly improved in abrasive environments.

- Q: Which is cheaper, angle iron or steel pipe?

- Steel pipe is not only used to transport fluid and powder solid, exchange heat energy, and manufacture mechanical parts and containers, but also is an economic steel. It can reduce weight and save 20 to 40% of metal by using steel pipe to make building structure, network frame, prop and mechanical support. Moreover, it can realize factory mechanization construction. Using steel pipe to manufacture road bridge can not only save steel, simplify construction, but also greatly reduce the area of coating protective layer, save investment and maintenance cost.

- Q: Are steel angles suitable for manufacturing support brackets for conduits?

- Yes, steel angles are suitable for manufacturing support brackets for conduits. Steel angles are commonly used in construction and manufacturing industries due to their strength and durability. They provide excellent structural support and can withstand heavy loads. When used to manufacture support brackets for conduits, steel angles can effectively secure and hold the conduits in place, ensuring stability and preventing any potential damage or accidents. Additionally, steel angles can be easily customized to meet specific requirements, such as size, shape, and finish, making them a versatile choice for manufacturing support brackets for conduits.

- Q: How do you calculate the torsional strength of a steel angle?

- In order to calculate the torsional strength of a steel angle, several factors must be considered. First and foremost, it is crucial to determine the moment of inertia of the steel angle's cross-section. This can be achieved by utilizing the formula for the moment of inertia of a rectangular shape, namely (b * h^3)/12. Here, b represents the base width and h stands for the angle's height. Once the moment of inertia is established, it becomes possible to calculate the maximum shear stress using the equation T = (M * c)/I. In this formula, T signifies the torsional strength, M denotes the applied torque, c represents the distance from the centroid of the angle to the outermost fiber, and I symbolizes the moment of inertia. Determining the maximum allowable shear stress for the steel angle is achievable by taking into account the material properties of the steel. This value can be retrieved from engineering handbooks or specifications. Lastly, the torsional strength of the steel angle can be calculated by multiplying the maximum allowable shear stress by the moment of inertia of the angle. It is important to note that this calculation assumes the steel angle is only subjected to pure torsion, without any bending or additional external loads. If the angle is exposed to combined loads, more intricate calculations may be necessary to determine the torsional strength.

- Q: Are steel angles suitable for earthquake-prone areas?

- Due to their exceptional structural properties, steel angles find widespread use in construction, especially in areas prone to earthquakes. The L-shaped configuration of steel angles imparts significant stability and strength, rendering them ideal for withstanding seismic forces. Renowned for their high tensile strength and resistance to bending and twisting, steel angles play a vital role in earthquake situations. Moreover, steel is a ductile material capable of undergoing substantial deformation without failing, thereby absorbing a portion of the seismic energy generated. This flexibility effectively prevents catastrophic structural collapse during earthquakes. Additionally, steel angles can be easily fastened together through bolting or welding, ensuring efficient and cost-effective construction processes. Nonetheless, it is crucial to emphasize that the design and construction of structures in earthquake-prone areas must adhere to local building codes and regulations to guarantee maximum safety.

- Q: Are steel angles suitable for outdoor staircases?

- Yes, steel angles are suitable for outdoor staircases. Steel is known for its durability, strength, and resistance to weathering, making it an excellent choice for outdoor applications. Steel angles provide structural support and stability to staircases, ensuring they can withstand heavy loads and constant use. Additionally, steel angles can be coated or painted to provide further protection against rust and corrosion, prolonging their lifespan. Overall, using steel angles for outdoor staircases is a reliable and long-lasting solution.

- Q: What are the different types of steel angles used in machinery?

- Machinery commonly utilizes various types of steel angles. Equal-leg angles, also known as L-shaped or L-angle steel, are one of the most frequently employed varieties. These angles have identical dimensions on both sides and form a 90-degree angle. Their purpose in machinery is to provide structural support, stability, and reinforcement for joints and connections. Unequal-leg angles, on the other hand, possess different dimensions on each side, resulting in an uneven angle. This type of angle is often utilized in machinery that necessitates specific weight distribution or load-bearing requirements. It allows for greater design flexibility due to its uneven nature. Rounded steel angles, also referred to as rounded corner angles or round bars, are another option. These angles have rounded edges instead of sharp corners, making them suitable for machinery applications where safety is a concern. The rounded edges reduce the risk of injuries caused by sharp corners. Slotted steel angles are also available, featuring one or more holes or slots along their length. These slots facilitate easy adjustment and mounting of components, making them appropriate for machinery that requires frequent modifications or customization. Moreover, stainless steel angles are extensively used in machinery. Stainless steel possesses excellent corrosion resistance, making it ideal for machinery operating in harsh or corrosive environments like marine or chemical applications. In conclusion, the selection of steel angle in machinery is dependent on specific application requirements, encompassing structural needs, load-bearing capacity, safety considerations, and environmental factors.

- Q: What are the different types of steel angles used in storage racks?

- Storage racks commonly utilize various types of steel angles to ensure strength and stability, facilitating efficient storage and organization of items. 1) The most frequently employed steel angle in storage racks is the equal angle. It possesses identical sides and serves as the primary support beam in the rack's structure. The balanced weight distribution and stability it offers make it ideal for this purpose. 2) Unequal angles, as the name implies, have varying side lengths. These angles find application in storage racks that necessitate specific weight distribution or load-bearing requirements. The longer side of the unequal angle provides additional support for heavier items or different storage configurations. 3) Slotted angles are versatile, allowing convenient adjustment and customization of storage rack systems. They feature slots along their length, enabling the addition of shelves, dividers, or other accessories as required. Slotted angles are commonly found in warehouses or industrial settings where frequent reconfiguration of the rack system is necessary. 4) Perforated angles contain holes punctured along their length, offering improved ventilation and visibility for stored items. They are often employed in storage racks for items that require airflow or in retail settings where product visibility holds significance. 5) Corner angles, on the other hand, are L-shaped steel angles used to reinforce and strengthen the corners of storage racks. They provide additional support and stability, preventing the rack from collapsing or tipping over when heavy items are stored on the shelves. Ultimately, the choice of steel angle for storage racks relies on specific requirements such as load-bearing capacity, customization options, ventilation needs, and visual appeal. By selecting the appropriate steel angle, storage racks can be optimized for maximum efficiency and durability.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 65*65mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords