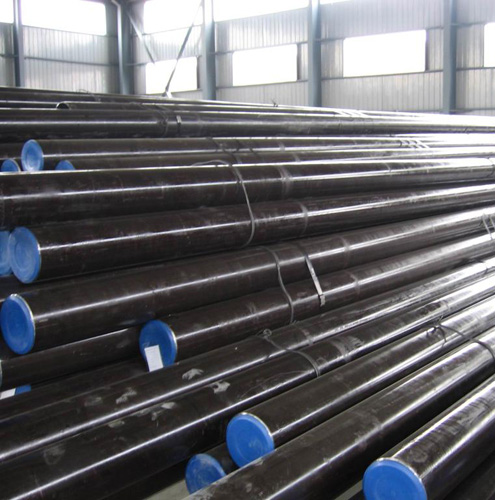

Hot rolled High Quality Bearing Special Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot rolled Bearing Special Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Product Advantages:

OKorder's Hot rolled Bearing Special Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Bearing Steel

1. Dimensional sizes: Thickness: 14~100mm.Length:3000~5800mm,Diameter :14-500mm

2.Chemical composition:

C | Si | Mn | Cr | Ni | Cu |

Equal or less than | |||||

0.95-1.05 | 0.15-0.35 | 0.20-0.40 | Cr:1.30-1.65 | 0.30 | 0.25 |

3. Grade: SAE51200/ GCr15 / 100cr6

4. Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

5. Surface requirements: Black, grinding, bright, polish

6. Characters:

1) Comprehensive properties

2) Good performance in cutting and processing after spheroids annealing

3) High hardness and homogenization after quenching and tempering

4) High abrasive resistance and fatigue resistance

7. Payment terms: T/T or L/C at sight

Packaging & Delivery of Bearing Steel

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

Note:

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electro-slag re-melting (ESR)steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: What are the different forging techniques used for special steel?

- There are several forging techniques used for special steel, including open die forging, closed die forging, and ring rolling. Open die forging involves shaping the steel between flat dies, allowing for flexibility in the size and shape of the final product. Closed die forging, on the other hand, uses shaped dies to shape the steel into a specific form. Ring rolling is a technique used to produce seamless rings by rolling a heated steel billet between two rotating rolls to achieve the desired shape. These techniques ensure the production of high-quality, customized special steel products for various applications.

- Q: How does special steel contribute to the power generation machinery industry?

- Special steel plays a crucial role in the power generation machinery industry by contributing to the efficiency, reliability, and durability of power generation equipment. Firstly, special steel possesses exceptional mechanical properties, such as high strength, toughness, and temperature resistance. These properties make it ideal for manufacturing key components of power generation machinery, such as turbines, generators, and boilers. The superior strength and toughness of special steel enable these components to withstand high pressures, extreme temperatures, and harsh operating conditions, ensuring the safe and efficient operation of power plants. Moreover, special steel alloys can be specifically designed to resist corrosion, erosion, and wear, which are common challenges faced by power generation equipment. Corrosion can be caused by the chemical reactions between metals and the environment, while erosion and wear result from the high-speed flow of steam, water, or gases. By utilizing corrosion-resistant and wear-resistant special steel, power generation machinery can operate for longer periods without significant degradation, reducing maintenance requirements and downtime. Another significant contribution of special steel to the power generation machinery industry is its ability to retain magnetic properties at elevated temperatures. This property is crucial for electrical generators, as it ensures optimal performance and efficiency. Special steel with excellent magnetic properties enables generators to produce electricity with minimal energy losses due to heat, resulting in higher power output and reduced energy consumption. Furthermore, the design flexibility of special steel allows for the production of customized components, tailored to the specific requirements of different power generation technologies. For instance, in nuclear power plants, special steel alloys with high resistance to radiation and neutron embrittlement are used for the construction of reactor pressure vessels and other critical components. In renewable energy systems like wind turbines, special steel with superior fatigue resistance is utilized to withstand the cyclic loading experienced by turbine blades. In summary, special steel significantly contributes to the power generation machinery industry by enhancing the efficiency, reliability, and durability of power generation equipment. Its exceptional mechanical properties, corrosion resistance, wear resistance, magnetic properties, and design flexibility make it indispensable for manufacturing components that can withstand extreme conditions and ensure the continuous and efficient generation of electricity.

- Q: How is special steel used in the construction manufacturing process?

- Special steel is used in the construction manufacturing process for its unique properties such as high strength, durability, and resistance to corrosion. It is commonly used to fabricate structural components, reinforcement bars, and other critical elements in buildings, bridges, and infrastructure projects. Additionally, special steel alloys are utilized in the production of specialized tools and machinery used in the construction industry.

- Q: How does special steel perform in high-pressure and high-temperature environments?

- Special steel performs exceptionally well in high-pressure and high-temperature environments due to its unique composition and properties. It exhibits excellent strength, toughness, and resistance to corrosion, making it ideal for withstanding extreme conditions. Additionally, special steel can maintain its mechanical properties, structural integrity, and dimensional stability even under intense heat and pressure, ensuring reliable performance and longevity in such environments.

- Q: Can special steel be used in mining applications?

- Yes, special steel can be used in mining applications. Special steel, also known as alloy steel, is specifically designed to have enhanced properties such as increased strength, durability, and resistance to wear and corrosion. These properties make it highly suitable for various mining applications where the equipment and machinery are subjected to extreme conditions, including heavy loads, abrasive materials, and exposure to water or chemicals. In mining, special steel is commonly used for manufacturing drill bits, cutting tools, crushing and grinding equipment, conveyor belts, and structural components of mining machinery. For example, drill bits made from special steel alloys have improved hardness and toughness, allowing them to effectively penetrate hard rock formations. Similarly, crushing and grinding equipment that utilizes special steel components can withstand the high stress and impact forces encountered during the extraction and processing of minerals. Moreover, special steel alloys provide better resistance to corrosion and wear, which are common challenges in mining environments. This helps to extend the lifespan of mining equipment, reduce maintenance costs, and enhance operational efficiency. Additionally, special steel can be tailored to meet specific requirements, allowing manufacturers to optimize the performance of mining equipment for different mining applications and conditions. Overall, the use of special steel in mining applications offers numerous benefits in terms of improved performance, durability, and cost-effectiveness. Its unique properties make it an essential material in mining operations, enabling the extraction and processing of minerals in a more efficient and sustainable manner.

- Q: What are the properties of wear-resistant stainless steel?

- Wear-resistant stainless steel possesses properties such as high hardness, excellent corrosion resistance, and good toughness. It is designed to withstand abrasion, erosion, and wear caused by friction, making it ideal for applications where durability and long-lasting performance are crucial, such as in industrial machinery, cutting tools, and automotive components.

- Q: What are the different medical grades of special steel?

- Special steels used in the medical field are typically classified into different grades based on their unique properties and characteristics. These grades are specifically designed to meet the stringent requirements of medical applications, such as surgical instruments, implants, and medical devices. Some of the commonly known medical grades of special steel include: 1. Stainless Steel: Stainless steel is the most widely used medical grade of special steel due to its excellent corrosion resistance and biocompatibility. It contains high amounts of chromium and nickel, which provide resistance against corrosion and make it suitable for use in implants and surgical instruments. 2. Titanium Alloys: Titanium alloys are lightweight yet strong, making them ideal for medical applications such as orthopedic implants, dental implants, and cardiovascular devices. These alloys exhibit high biocompatibility and have excellent resistance to corrosion and fatigue, ensuring long-term durability. 3. Cobalt-Chromium Alloys: Cobalt-chromium alloys possess exceptional strength, wear resistance, and high-temperature stability, making them suitable for implantable devices like hip and knee replacements. They have excellent biocompatibility and offer a good balance between strength and flexibility. 4. Nitinol: Nitinol is a shape memory alloy composed of nickel and titanium. It displays unique properties, such as superelasticity and shape memory effect. Nitinol is commonly used in medical devices like stents, orthodontic wires, and vascular closure devices due to its excellent biocompatibility and ability to adapt to various physiological conditions. 5. High Carbon Stainless Steel: High carbon stainless steel is a specialized grade used in surgical instruments that require exceptional sharpness, hardness, and wear resistance. This grade allows for the production of extremely fine and precise cutting edges, making it suitable for delicate procedures. These are just a few examples of the medical grades of special steel used in the healthcare industry. Each grade offers specific advantages depending on the intended application, and their selection is crucial to ensure optimal performance, biocompatibility, and patient safety.

- Q: How does special steel meet the requirements of specific industries?

- Special steel meets the requirements of specific industries by offering exceptional strength, durability, and resistance to corrosion, heat, and wear. Its unique composition and manufacturing process allow it to withstand extreme conditions and perform efficiently in diverse applications such as automotive, aerospace, energy, construction, and manufacturing. Additionally, special steel can be tailored to meet the specific needs of each industry, ensuring optimal performance and reliability in their respective operations.

- Q: How are cobalt-based alloys used in dental applications?

- Cobalt-based alloys are commonly used in dental applications due to their high strength, corrosion resistance, and biocompatibility. These alloys are used in dental prosthetics, such as crowns, bridges, and dentures, to provide durability and stability. Additionally, cobalt-based alloys are often used in orthodontic appliances, implants, and surgical instruments due to their excellent mechanical properties and resistance to wear and deformation.

- Q: How does special steel perform in high-temperature creep resistance?

- Special steel is known for its exceptional performance in high-temperature creep resistance. Creep refers to the tendency of a material to deform or strain under constant stress when exposed to elevated temperatures. In such conditions, ordinary steels may exhibit significant creep, leading to a loss of mechanical properties and potential failure. However, special steels are specifically designed to withstand high-temperature creep, making them ideal for applications where resistance to time-dependent deformation is critical. These steels are often alloyed with elements such as chromium, molybdenum, and vanadium, which enhance their high-temperature properties. The alloying elements in special steels form stable carbides and nitrides, which act as strengthening agents, inhibiting grain growth, and preventing dislocation movement. This results in improved creep resistance and structural stability even at extreme temperatures. Additionally, special steels often undergo heat treatment processes such as quenching and tempering, which further enhance their creep resistance and overall mechanical performance. Furthermore, the microstructure of special steels is carefully controlled during the manufacturing process to ensure optimal creep resistance. Fine-grained structures with a high density of precipitates or second-phase particles are typically developed, which hinder dislocation movement and improve creep strength. In summary, special steels exhibit exceptional high-temperature creep resistance due to their alloying elements, heat treatment processes, and controlled microstructures. These steels can reliably withstand prolonged exposure to elevated temperatures without significant deformation or loss of mechanical properties, making them invaluable in industries such as aerospace, power generation, and petrochemicals where high-temperature applications are common.

Send your message to us

Hot rolled High Quality Bearing Special Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords