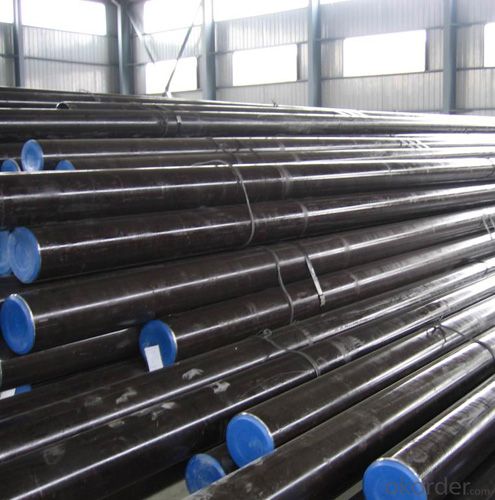

High Quality Hot rolled Bearing Special Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot rolled Bearing Special Steel Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Product Advantages:

OKorder's Hot rolled Bearing Special Steel Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Bearing Steel

1. Dimensional sizes: Thickness: 14~100mm.Length:3000~5800mm,Diameter :14-500mm

2.Chemical composition:

C | Si | Mn | Cr | Ni | Cu |

Equal or less than | |||||

0.95-1.05 | 0.15-0.35 | 0.20-0.40 | Cr:1.30-1.65 | 0.30 | 0.25 |

3. Grade: SAE51200/ GCr15 / 100cr6

4. Heat Treatment:

Soft annealing: heat to 680-720°C, cool slowly.

Hardness after annealing: Max. 241 HB

Hardening: 820 - 850 °C

Normalizing temperature: 840-880°C

Tempering: 540-680°C

5. Surface requirements: Black, grinding, bright, polish

6. Characters:

1) Comprehensive properties

2) Good performance in cutting and processing after spheroids annealing

3) High hardness and homogenization after quenching and tempering

4) High abrasive resistance and fatigue resistance

7. Payment terms: T/T or L/C at sight

Usage & Applications of Bearing Steel

Our products have been used in all kinds of areas, such as aviation, aerospace, navigation, nuclear, energy, chemical industry, electronic information, petrochemical, automotive, instrument and meter, Communication ,transportation, and medical instruments, etc. Bearing ring,steel rolling mill ,machinery, 100Cr6 bearing steel ball is widely used in high-speed and low-noise bearing, bicycle, motorcycle, automobile, bags, electronics.

Packaging & Delivery of Bearing Steel

Mark: Heat No. will be cold stamped and Steel grade, diameter (mm), length (mm), and the manufacturer LOGO and weight (kg) is painted.

Standard seaworthy packing or as customer required

Delivery time: Within 30 days after order is confirmed.

Note:

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electro-slag re-melting (ESR)steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What are the most common alloys used in special steel?

- The most common alloys used in special steel are stainless steel, high-speed steel, tool steel, and carbon steel.

- Q: What are the different peening techniques used for special steel?

- There are several peening techniques used for special steel, including shot peening, ultrasonic peening, laser peening, and cavitation peening. Each technique involves using different methods and tools to introduce controlled compressive stresses into the material's surface, improving its mechanical properties and resistance to fatigue, stress corrosion, and other forms of degradation.

- Q: Can special steel be used in the production of springs for automotive suspension?

- Yes, special steel can be used in the production of springs for automotive suspension. Special steel, such as high-strength or alloy steel, is often preferred for its improved durability, strength, and resistance to fatigue. These properties are critical for springs in automotive suspension systems, as they need to withstand the constant stress and load of the vehicle's weight and provide a smooth ride.

- Q: How does special steel contribute to reducing product failures in high-stress applications?

- Special steel contributes to reducing product failures in high-stress applications by providing enhanced mechanical properties and improved resistance to wear, corrosion, and fatigue. Its superior strength, toughness, and durability enable it to withstand extreme conditions and loads, ensuring the longevity and reliability of the products. Additionally, special steel allows for precise engineering and manufacturing, resulting in components that can withstand high stress without deformation or failure.

- Q: What is the role of heat treatment in special steel?

- Heat treatment plays a crucial role in enhancing the properties and performance of special steel. Special steel refers to alloys that are specifically designed to have unique characteristics, such as high strength, corrosion resistance, or heat resistance. Heat treatment involves subjecting the steel to controlled heating and cooling processes to alter its microstructure, resulting in desired properties. One of the key roles of heat treatment in special steel is to improve its mechanical properties. By carefully controlling the heating temperature and cooling rate, the steel's hardness, strength, and toughness can be enhanced. For example, through processes like quenching and tempering, special steel can be made significantly stronger and more resistant to wear and fatigue. This makes it suitable for applications where high strength and durability are required, such as in the construction of machinery, tools, or aerospace components. Heat treatment also helps to optimize the steel's resistance to corrosion. Special steel is often used in environments where it is exposed to harsh conditions, such as corrosive chemicals or high temperatures. By subjecting the steel to specific heat treatment processes, like annealing or precipitation hardening, the steel can develop a more stable microstructure that improves its resistance to corrosion and oxidation. This ensures that the special steel maintains its integrity and performance even in challenging environments. Furthermore, heat treatment can modify the steel's heat resistance properties. Special steel is frequently used in applications where it is exposed to high temperatures, such as in the manufacturing of turbines or exhaust systems. Through heat treatment techniques like normalization or hardening, the steel can be made more resistant to deformation, cracking, or softening at elevated temperatures. This enables the special steel to retain its strength and structural integrity even under extreme heat conditions. In summary, heat treatment plays a crucial role in optimizing the mechanical, corrosion resistance, and heat resistance properties of special steel. By carefully manipulating the steel's microstructure through controlled heating and cooling processes, heat treatment enhances the steel's strength, durability, and performance, making it suitable for a wide range of demanding applications.

- Q: What are the different defense grades of special steel?

- Enhanced properties are possessed by special steel, which is a distinct category of steel that is specifically designed. These properties include increased strength, durability, and resistance to various environmental factors. In the realm of defense applications, special steel is frequently utilized to produce armor and protective components for military vehicles, aircraft, and naval vessels. The defense grades of special steel are classified based on their specific characteristics and performance levels. One of the most commonly utilized defense grades of special steel is referred to as ballistic steel. Ballistic steel is engineered to offer exceptional resistance against ballistic threats, which encompass bullets and shrapnel. It possesses high tensile strength and hardness, which enables it to endure the impact and penetration of projectiles. Several grades of ballistic steel exist, such as MIL-A-46100, MIL-A-12560, and AR500, each providing varying levels of protection against different types of ammunition. Another defense grade of special steel is known as blast-resistant steel. This form of steel is designed to withstand explosions and minimize the damage caused by shockwaves, fragmentation, and heat. It is commonly employed in the construction of blast-resistant walls, doors, and windows for military bases, embassies, and critical infrastructure facilities. Blast-resistant steel grades are classified based on their capacity to withstand different levels of explosive forces, with higher grades offering greater protection. Furthermore, specialized grades of special steel are employed for anti-vehicle applications. These grades, such as Armox and Ramor, are engineered to resist the impact of heavy-caliber projectiles and explosive devices, making them suitable for the production of armored vehicles and personnel carriers. They possess a combination of high hardness, toughness, and energy absorption properties, ensuring the safety of military personnel on the battlefield. In conclusion, the defense grades of special steel are varied and tailored to meet the specific requirements of diverse defense applications. They provide essential protection and ensure the safety of military personnel and equipment in challenging and hostile environments. The appropriate grade is chosen based on the nature of the threat, the level of protection required, and the specific design and performance criteria of the defense application.

- Q: Can special steel be used in the chemical processing equipment manufacturing industry?

- Yes, special steel can be used in the chemical processing equipment manufacturing industry. Special steel is often preferred in this industry due to its high corrosion resistance, ability to withstand high temperatures, and excellent mechanical properties, making it suitable for handling various corrosive chemicals and harsh operating conditions.

- Q: What are the different chemical processing grades of special steel?

- There are several different chemical processing grades of special steel, including stainless steel, tool steel, high-speed steel, and alloy steel.

- Q: How is high-strength steel used in the automotive industry?

- High-strength steel is widely used in the automotive industry for its ability to enhance the safety and performance of vehicles. It is used in various components such as the frame, chassis, and body structure to improve structural integrity, reduce weight, and provide better crash protection. Additionally, high-strength steel allows automakers to design vehicles with improved fuel efficiency and increased load-carrying capacity, making it a crucial material in modern automotive manufacturing.

- Q: What is the significance of alloying elements in special steel?

- Alloying elements in special steel play a crucial role in enhancing its properties and performance. These elements, such as chromium, nickel, manganese, and molybdenum, are added to improve characteristics like strength, hardness, corrosion resistance, and heat resistance. The combination and proportion of alloying elements determine the specific properties of the steel, making it suitable for various applications, such as manufacturing aircraft parts, automotive components, or tools. Overall, alloying elements greatly contribute to the versatility and functionality of special steel.

Send your message to us

High Quality Hot rolled Bearing Special Steel Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords