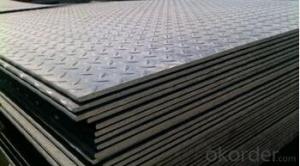

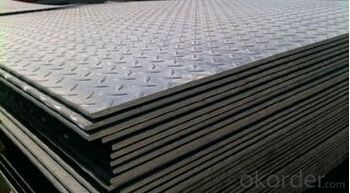

Hot rolled checkered steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: | Hot Rolled Steel Coils/Sheets |

Material: | Q195,Q235,A36,SS400,S235JR,Q345,ST37-2, CCSB etc |

Standard : | JIS G3002 GB/T251B |

Technique: | hot rolled |

Thickness | 1.2mm to 200mm |

Tolerance of thickness: | :+/-0.03mm |

Width: | 750mm-2000mm |

Tolerance of width: | :+/-5.00mm (aiming to +/-2.00mm) |

Normal width: | 914mm, 1000mm, 1200mm, 1219mm, 1250mm,1500mm |

Length: | According to requirement |

Coil ID: | 508mm-610mm |

Coil Weight: | 10-25 Metric Tons |

Surface: | Black, Chromate, fingerprint resistant treatment, slight oiled or non-oiled, dry |

Port of Loading: | Tianjin/Shanghai port |

Packaging Details: | Standard export packing or according to the clients required |

Delivery Time | Within 30 days after received 30% deposit or workable L/C |

Payment Terms: | L/C,T/T |

|

|

- Q: What are the dimensions of steel coils?

- The dimensions of steel coils can vary depending on the specific application and industry. However, they are typically available in widths ranging from 0.5 inches to 72 inches and thicknesses ranging from 0.005 inches to 0.5 inches. The length of steel coils can vary as well, but they are commonly found in lengths of 100 feet to 1000 feet.

- Q: There's this huge community of steelians (steelites?) in my town. Has anybody heard of this Dr. Steel?

- Here are twenty that I grew up listening to, such a lot of them within the loved ones auto in which I had 0 manage over what used to be performed. But I nonetheless love each one in every of them to nowadays... Sea Cruise- Frankie Ford Walk Don't Run- The Ventures Don't Worry Baby- The Beach Boys Bus Stop- The Hollies These Boots Are Made For Walking- Nancy Sinatra I Saw Her- Mamas Papas A Taste Of Honey- Herb Alpert Everybody's Talking At Me- Nilsson Superstar- The Carpenters Indian Reservation- Paul Revere The Raiders Come And Get It- Badfinger Tell Me Something Good- Rufus Come And Get Your Love- Redbone Higher Ground- Stevie Wonder Waterloo- ABBA How Long (Has This Been Going On)- Ace The Hustle- Van McCoy More More More- Andrea True Connection Shining Star- Earth, Wind Fire Got To Give It Up- Marvin Gaye

- Q: I am going to be working as a mechanic at my school and I just wanted to know if I should get the steel toe boots or regular. I heard that steel toe boots can be dangerous and uncomfortable. The mechanics recommended getting steel toe to be safe but i'm not sure.

- Steel toe boots they protect your feet and toes a lot better and if u are going to be working they would be better to have than soft toe boots

- Q: What are the dimensions of steel coils used in the construction equipment industry?

- The dimensions of steel coils used in the construction equipment industry can vary depending on the specific application and requirements. However, there are common standard dimensions that are often used. Steel coils used in the construction equipment industry typically have a width ranging from 600mm to 2000mm. The thickness of these coils can range from 0.5mm to 25mm or even higher, depending on the intended use and structural requirements. The weight of steel coils used in construction equipment industry can vary significantly, ranging from a few hundred kilograms to several tonnes. The weight is typically determined by the dimensions and thickness of the coil, as well as the specific grade and type of steel being used. It is important to note that these dimensions are not fixed and can be customized based on the specific needs of the construction equipment industry. Manufacturers and suppliers can provide steel coils in various dimensions to meet the specific requirements of construction equipment manufacturers and contractors.

- Q: What are the different types of steel coil recoiling methods?

- There are several different types of steel coil recoiling methods, including oscillating recoiling, flying shear recoiling, and rotary recoiling.

- Q: How are steel coils inspected for width?

- To ensure compliance with the necessary specifications, various techniques are employed to inspect the width of steel coils. Among these methods, a commonly used one is the utilization of a caliper gauge, also referred to as a micrometer. This gauge makes direct contact with the coil edges to measure its width. The operator places the gauge at multiple points along the width and records the measurements. This approach guarantees precise measurements and facilitates the identification of any inconsistencies or deviations in the desired width. Another technique employed for width inspection is laser measurement. In this method, laser sensors are positioned on both sides of the coil, emitting a laser beam that scans across the width. By detecting the distance between the edges of the coil, the sensors provide accurate width measurements. This non-contact approach is highly efficient, swiftly inspecting the coil's width without causing any physical damage or requiring physical contact. Moreover, advanced systems employ computer vision technology for width inspection. This involves the use of cameras and image processing software to capture images of the coil's edges. The software then analyzes these images and calculates the width based on the detected edges. This method enables rapid inspections and can identify any irregularities in the coil's width. In conclusion, the inspection of steel coil width involves a combination of physical gauges, laser sensors, and computer vision technology. These methods ensure that the coils conform to the required width specifications and play a crucial role in maintaining quality control throughout the steel manufacturing process.

- Q: which type of carbon steel does not have manganese

- None. Mn is a trace impurity in all steels, if you look carefully enough. If you want to find a steel where Mn is not intentionally added, start looking at the alloy composition specifications, there are hundreds of steels. Why are you worried about Mn? Mn is typically added to steels for a very good reason.

- Q: How are steel coils used in the manufacturing of shipbuilding?

- Steel coils are used in shipbuilding for several purposes. They are primarily used to fabricate the hull and structural components of ships. Steel coils are cut, shaped, and welded to form various ship sections, such as the hull plates, bulkheads, and decks. These coils provide the necessary strength, durability, and corrosion resistance required for marine applications. Additionally, steel coils are also used to manufacture other shipbuilding components like piping, machinery, and equipment, ensuring the overall integrity and functionality of the vessel.

- Q: every time i look for steel over the internet like to build cars motorcycles ect i only get steel pipes where can i get steel sheets

- This okorder /... Most towns have a steel supply house/ business, check your yellow pages. Also check with local welding and machine shops. They can give you ideas and or their suppliers. They often have bits and pieces that you might buy, instead of ordering a full sheet of material. Wingman

- Q: What are the common welding methods used for steel coils?

- There are several common welding methods used for steel coils, depending on the specific requirements and applications. Some of the most widely used methods include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW uses an electrode coated in flux to create an arc between the electrode and the base metal. This method is commonly used for its simplicity and versatility, making it suitable for a wide range of steel coil welding applications. 2. Gas Metal Arc Welding (GMAW): Also known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. This method is favored for its high welding speed and excellent control over the welding process. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a continuously fed tubular electrode filled with flux to protect the weld pool. This method is often preferred for its high deposition rates and ability to weld thicker steel coils, making it ideal for heavy-duty applications. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an inert gas shield to protect the weld pool. This method is commonly used for its precise control, high-quality welds, and ability to weld thin materials. 5. Submerged Arc Welding (SAW): SAW involves the formation of an arc between a continuously fed wire electrode and the steel coil, while a granular flux covers the arc and weld area. This method is frequently used for its high productivity and ability to weld thick materials. Each of these welding methods has its own advantages and limitations, and the choice of method depends on factors such as the thickness of the steel coil, desired welding speed, weld quality, and application requirements.

Send your message to us

Hot rolled checkered steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords