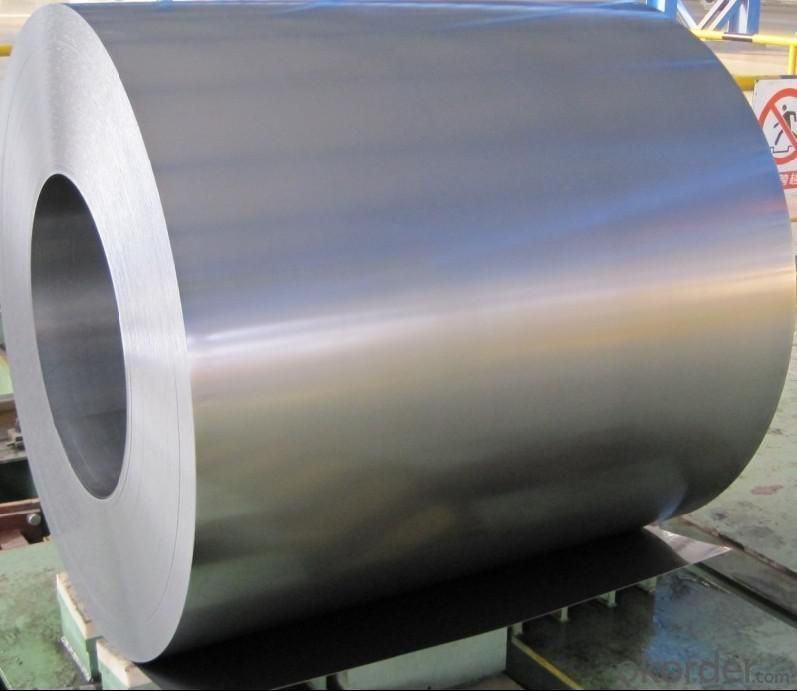

Hot-dip Zinc Coating Steel Coil Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls with Best Quality

Product Description:

Structure:

Hot-dip galvanized steel coils It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Main Features:

• Excellent anticorrosive property

• High strength

• Good formability

Specifications:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Processability | Yield strength | Elongation % | 180°cold-bending | |

Common PV | - | 270-500 | d=0,intact,no zinc removal | |

Mechanical interlocking JY | - | 270-500 | d=0,intact,no zinc removal | |

Structure JG | >=240 | >=370 | d=0,intact,no zinc removal | |

Deep drawn SC | - | 270-380 | d=0,intact,no zinc removal | |

EDDQ SC | - | 270-380 | d=0,intact,no zinc removal |

- Q: Are steel coils used in the aerospace industry?

- Yes, steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, structural parts, and engine components.

- Q: Steel seems to be much less expensive. What is the reason why? I've heard steel will ruin a barrel after time....is that true? But with the price difference maybe it don't matter? Is steel reliable? What are the negatives about steel I should know before buying?

- steel bore - brass copper chrome-lined steel bore - steel is fine. steel jacketed bullets are harder than copper jacketed bullets and would result in higher pressure, more wear in a steel barrel than a chrome-steel barrel. chrome-lined steel is roughly 2X as hard as 4140 steel. even better, nitrated chrome steel is roughly 3-4X harder than 4140 steel. but it s fairly new is a bit pricey. most AR barrels are chrome-lined. you can tell easily if the chamber and bore has a silvery look. regular steel is just black. steel cased rounds are reliable, however plain, uncoated steel cases may feed with some difficulty due to a rougher case finish that results in more friction than the polished, smooth brass cases. cheap ammo (doesn't matter if steel or brass) always shoots more dirty. aside from that I would recommend you try a bit of each of go with whatever shoots most accurate and feeds without problem.

- Q: How are steel coils used in the manufacturing of pipelines?

- Steel coils are used in the manufacturing of pipelines as they are rolled into sheets to form the base material for the pipes. These coils are uncoiled and passed through a series of machines where they are cut, shaped, and welded together to create the desired length and diameter of the pipeline.

- Q: What are the main challenges in handling and processing steel coils?

- The main challenges in handling and processing steel coils include their large size and weight, which require specialized equipment and techniques for safe transportation and storage. Coils also tend to have sharp edges, posing a risk of injury. Additionally, maintaining the integrity and quality of the steel during processing can be challenging due to the potential for surface damage, rust, or deformation. Proper handling, storage, and processing techniques are crucial for minimizing these challenges and ensuring the efficient production of steel products.

- Q: Can steel coils be coated with weather-resistant materials?

- Yes, steel coils can be coated with weather-resistant materials such as zinc, aluminum, or organic coatings to enhance their resistance to corrosion and exposure to harsh weather conditions.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- There are several methods of cut-to-length shearing for steel coils, each with its own advantages and applications. Some of the commonly used methods are: 1. Rotary Shearing: This method involves the use of a rotating shear blade that cuts through the coil. It offers high precision and can handle a wide range of material thicknesses. Rotary shearing is suitable for high-volume production and can achieve high cutting speeds. 2. Guillotine Shearing: In this method, a straight blade is used to cut through the coil. It is a versatile method that can handle various material thicknesses and widths. Guillotine shearing is relatively simple and efficient, making it a popular choice for many applications. 3. Slitting: Slitting involves making multiple longitudinal cuts in the coil to create narrower strips. It is commonly used when a coil needs to be divided into several smaller coils or when narrower strips are required for specific applications. Slitting can be done using either rotary or straight blades. 4. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the material, resulting in a clean and precise cut. It is ideal for cutting complex shapes or patterns and can handle both thin and thick steel coils. Laser cutting offers high accuracy and minimal material distortion. 5. Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through the coil. This method is suitable for a wide range of materials, including steel, and can achieve high accuracy. Waterjet cutting is often used for cutting thick coils or when heat-affected zones need to be minimized. Each method has its own strengths and limitations, and the choice depends on factors such as material thickness, required precision, production volume, and specific application requirements. The selection of the most appropriate method is crucial to ensure efficient and high-quality cut-to-length shearing for steel coils.

- Q: Steel coil from vertical to horizontal, what sling needs?

- The sling has little effect, but it is easy to damage the surface of rolled steel.

- Q: Can steel coils be coated with noise-reducing materials?

- Yes, steel coils can be coated with noise-reducing materials. These materials, such as rubber or polymer coatings, are designed to dampen vibrations and reduce noise generated during steel coil movement or processing. Coating steel coils with noise-reducing materials helps minimize noise pollution in various industrial applications.

- Q: Can steel coils be customized according to specific requirements?

- Yes, steel coils can be customized according to specific requirements. Manufacturers can tailor the dimensions, thickness, width, and coating of steel coils to meet the specific needs of their customers. This customization allows for greater flexibility and ensures that the steel coils are suitable for various applications and industries.

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems primarily for their strength and durability. They form the core structure of various components such as heat exchangers, condenser coils, and evaporator coils. The steel coils provide stability and support, ensuring the longevity and efficiency of HVAC systems by withstanding high temperatures, pressure, and constant use.

Send your message to us

Hot-dip Zinc Coating Steel Coil Building Roof Walls

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords