Hot Dip Galvanizing Steel Coils with GB3091-84 and BA139 Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Hot Dip Galvanizing Steel Coils:

Hot galvanizing (also called hot dip galvanizing) is a kind of effective metallic anti-corrosion mode and mainly applied to metallic structure facilities in various industries. A steel piece subjected to rust removal is dipped into melted zinc at the temperature of nearly 500℃, and a zinc layer is coated on the surface of the steel structure piece, so that the aim of resisting corrosion is achieved. The flow of the hot galvanizing: acid cleaning of finished products—water washing—adding of auxiliary plating solution—drying—rack plating—cooling—medicinal chemistry—cleaning—grinding—finishing of hot galvanizing. The hot dip galvanizing process is developed from old hot plating methods, and it has a history of over 140 years since its application to the industry of France in 1836. However, the hot dip galvanizing industry has been greatly developed in recent three decades with the quick development of cold-strip steel.

2.Main features of Hot Dip Galvanizing Steel Coils:

With excellent cold-rolling steel strips as a base material, it has the advantages of

.Good manufacturing performance

.High impact resistance

.Uniform plating thickness

.High adhesive force

.No peeling after forming

.High corrosion resistance

3.Hot Dip Galvanizing Steel Coils Images:

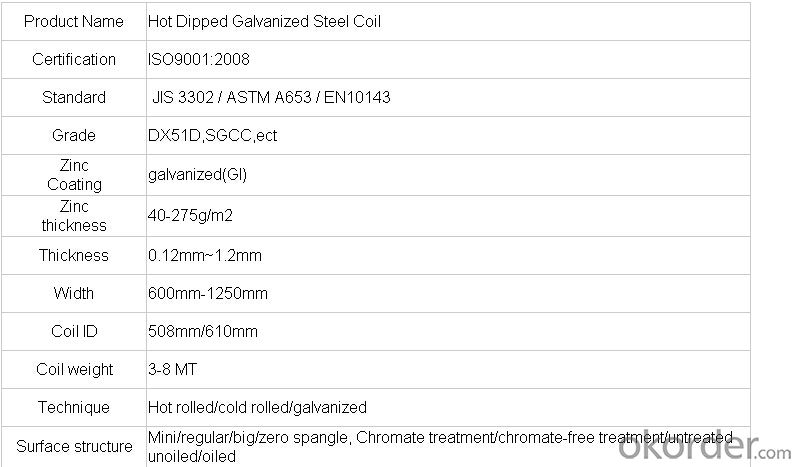

4.Hot Dip Galvanizing Steel Coils Specification:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Ok I have a neodymium magnet, stuck to my fridge holding a old bottle cap opener for my beer it works fine. At the local rummage sale there was a beautiful cap opener my freind was selling for $0.25 she said had never beenUsed it was like 40 years old it is made a stainless steel. The magnet will not stick to it. I don't understand this looked this up and certain steels are not magnetic, I tried a experiment with my compass it don't point north as should it follows the bottle opener as I move it around it. If not magnetic why is this happening? Also tried placing near another neodymium magnet with a pull of about 200 lbs. Not I tiny bit of attraction to the metal. If so why is the tiny magnet in the compass attracted to it. But not a huge powerfull magnet.

- That's interesting that it caused deflection in the compass. A lot of stainless steels may be SLIGHTLY magnetic, because they have small amounts of ferrite or alpha-iron in them. Ferrite is one of the crystal phases of steel. It has a body-centered cubic (BCC) structure and it's responsible for the magnetism of ordinary steels. Adding certain elements like nickel, manganese, or molybdenum, changes the crystal structure of the steel to a face-centered cubic (FCC) structure, which is NOT magnetic. This crystal phase is known as Austenite or gamma-iron. However most iron alloys contain some impurities that may cause the steel to be not completely transformed into the FCC austenite phase, small areas remain as ferrite.

- Q: hello friends, I have some old 7.62x54r on stripper clips its nasty gunk on it can i use steel wool to glean it and still have it fire safely?

- * Yes, but I use both fine steel wool and Liquid Brasso Metal Polish on mine.* You can buy it at any Hardware and I believe Walmart carries it.* Great stuff.*

- Q: if steel is heated from room temperature (20c) to (500c) what would be the change in density?coefficient for linear expansion of steel 12x10^-6 k density of steel 7800 kg

- First you have to convert the coefficient of linear expansion to a coefficient of volumetric expansion. Multiply the coefficient of linear expansion by 3: Coefficient of expansion of steel,β:12E-6/°K x 3 = 36E-6/°K Difference in temperature: 480°K ΔV = VoβΔT ΔV = Vo x (0.000036) x 480 ΔV = 1m? x 0.017 ΔV = 0.017m? Originally, the steel was at 7800 kg/m? Now, the steel was at 7800 kg/ 1.017m?, or 7670 kg/m? Change in density = 7670 - 7800 = -130kg/m?

- Q: Can steel coils be customized in terms of size and shape?

- Yes, steel coils can be customized in terms of both size and shape to meet specific requirements and applications.

- Q: How are steel coils coated?

- Steel coils are typically coated through a process known as coil coating, which involves applying a protective layer to the surface of the steel. This is done by passing the coil through a series of rollers that apply the coating material evenly across the entire surface. The coating can be applied using various methods such as roll coating, spray coating, or electrostatic coating, depending on the desired finish and properties. The coated steel coils are then cured or baked to ensure the coating adheres properly and provides the desired level of protection and durability.

- Q: What kind of steel should be used for constructing a steel building?

- Quality okorder /

- Q: How are steel coils used in the production of steel containers?

- Steel coils are an essential component in the production of steel containers. These coils, made from flat-rolled steel, are used to create the main body of the container. Firstly, the steel coils are unwound and fed into a rolling mill, where they undergo a series of processes to shape and form the steel. This includes heating the coils to a specific temperature to make them more malleable and easier to work with. The hot coils are then passed through a series of rollers that gradually reduce their thickness and lengthen them to the desired size. This process is known as hot rolling. Once the steel coils have been rolled to the required thickness, they are then cooled and cut into sheets. These sheets are then further processed to remove any imperfections or irregularities, ensuring a smooth and uniform surface. This is done through processes such as pickling, where the sheets are treated with acid to remove any scale or rust, and cold rolling, where the sheets are passed through rollers at room temperature to achieve the desired thickness and surface finish. After the sheets have been cleaned and smoothed, they are then formed into the shape of the container. This is typically done through a process called stamping, where the steel sheets are pressed into a mold using a hydraulic press. The mold determines the shape and size of the container, and the steel sheets are pressed against it with immense force, resulting in the desired container shape. Once the containers have been formed, they undergo various finishing processes such as welding, painting, and coating to enhance their durability, appearance, and resistance to corrosion. These final touches ensure that the steel containers are of high quality and meet the required standards for their intended use. In summary, steel coils play a crucial role in the production of steel containers by providing the raw material from which the containers are formed. Through a series of processes, the steel coils are shaped, cut, and formed into sheets, which are then further processed and transformed into the desired container shape. The result is a durable and reliable steel container that can be used for various applications across industries.

- Q: Hi! does anyone know where can i find a building with a structure of steel frames, i need to do an analysis for school so i need joint details, girder details and such! PLEASE help me! thanks

- if u need to analyse a steel framed structure for joint details the best example would be of a mechanic workshop...the truss of such a workshop is always supported on a portal frame and in most of the case thats a steel structure...do keenly observe the joints at the footing plates that is connected to the girder section...nd also observe the joints in truss of such a frame....myslf m a civil engg. student.

- Q: I have steel on my 9.5 ti now.. ive heard about synthetic being stronger but it snaps when it hits something sharp.. opinions people?

- Steel is more dangerous, both in a fatal metal whip way and a metal splinters in my hand way. Steel weighs more. So why would anyone continue to use steel? Cost and care. Care: Steel can sit for years without having to worry about dry rot (as long as it's not out in too horrible of weather conditions). Steel is much more resistant to fraying. You don't have to baby steel so much to keep it in good conditions. Cost: As of right now, steel is less than half the cost of synthetic. A synthetic rope can cost as much as many electric winches which include a steel cable. I find that I don't use my winch nearly enough to warrent the extra care or cost of a synthetic. The weight savings would be nice, but I kind of ruined that a long time ago with the winch bumper, rock sliders, plate steel fenders/flares, belly armor and frame plating.

- Q: Can steel coils be used in the production of furniture?

- Furniture production can incorporate steel coils, which offer strength, durability, and stability. This raw material is commonly utilized in manufacturing different types of furniture like chairs, tables, and bed frames. Steel coils enable heavy-duty usage by providing the necessary resilience. Furthermore, their adaptability allows for various designs and sizes, granting versatility in furniture production. Transforming the coils into components such as frames or support structures establishes a solid foundation. Additionally, the use of steel coils in furniture production enhances aesthetics as they can be finished in diverse colors and coatings to match the desired style. Overall, steel coils are a prevalent and pragmatic choice for furniture manufacturers due to their strength, durability, and design potential.

Send your message to us

Hot Dip Galvanizing Steel Coils with GB3091-84 and BA139 Standards

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords