HOT- DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120 Dx51d+Z, DC01

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

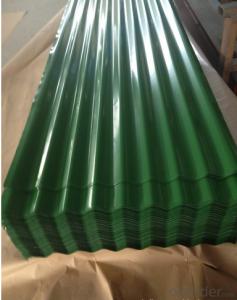

Hot DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120 Dx51d+Z, DC01

Description:

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal; Cold rolled plate by hot-dip galvanizing may extend the service life of 15-20 years.

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Application:

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

andard | EN 10142 | DX51D+Z, DX52D+Z, DX53D+Z |

JIS G3321 | SGCC, SGCD, SGCDD, SGC400 | |

ASTM A792M | CS type C, CS type B, DS, SS250 | |

Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

Thickness | 0.14mm-3.0mm | |

Width | 600mm-1600mm | |

Coil ID | 508mm, 610mm | |

Zinc coating | 60g/m2-450g/m2 | |

Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

Spangle types | Minimal spangle, zero spangle, regular and big spangle | |

FAQ

1. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

2.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

3. Is the sample available?

Yes, samples can be sent for test if you need.

- Q: What are the common methods of testing the durability of steel coils?

- Steel coils undergo various testing methods to assess their durability, strength, and resistance to different stresses and conditions. Some commonly used techniques include: 1. Tensile testing: This method measures the maximum stress a coil can bear before breaking or deforming by subjecting it to tension. It provides valuable insights into the strength and ductility of steel coils. 2. Bend testing: This method evaluates the flexibility and resistance to deformation of steel coils by bending them to a specific angle and checking for cracks or fractures. It is essential for assessing coil durability in industries like construction or automotive. 3. Impact testing: This method determines the ability of steel coils to withstand sudden shocks or impacts. It involves striking the coil with a heavy object and measuring energy absorption or deformation. Impact testing helps identify coil toughness and resistance to sudden loading conditions. 4. Corrosion testing: Steel coils often face corrosive environments like moisture or chemicals. Corrosion testing examines the resistance of steel to degradation caused by these agents. Salt spray or electrochemical testing simulates and evaluates coil durability in corrosive conditions. 5. Fatigue testing: This method assesses the ability of steel coils to endure repeated loading and unloading cycles. It subjects the coil to cyclic stresses until failure. Fatigue testing is crucial in machinery or infrastructure applications where coils experience repetitive loading. 6. Hardness testing: This method gauges the resistance of steel coils to indentation or scratching, providing information about their strength and wear resistance. Common hardness tests include Brinell, Rockwell, and Vickers methods. 7. Non-destructive testing: In addition to the destructive methods mentioned above, non-destructive techniques like ultrasonic testing, magnetic particle inspection, or X-ray testing are used to detect internal defects or flaws without damaging the coil. By utilizing these testing methods, manufacturers and industries can ensure that steel coils meet the required durability standards and perform reliably in their intended applications.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are highly regarded for their exceptional strength and durability, making them superior to other types of metal coils. Steel is known for its high tensile strength, allowing it to withstand heavy loads and resist deformation. This makes steel coils ideal for applications that require a high level of structural integrity, such as in the construction and automotive industries. In addition to their strength, steel coils also offer excellent corrosion resistance. Various protective layers, such as zinc or paint, can be applied to steel to prevent rusting and ensure longevity. This makes steel coils suitable for outdoor and marine environments where exposure to moisture and harsh weather conditions is common. Furthermore, steel coils have a diverse range of mechanical properties that can be customized through different manufacturing processes. This allows for the production of steel coils with specific characteristics, including high ductility, heat resistance, or electrical conductivity, to meet the requirements of various industries. When compared to other metal coils, such as aluminum or copper, steel coils often have a lower cost. Steel is one of the most economical metals available, and its abundance in nature contributes to its affordability. This makes steel coils a cost-effective choice for many applications, especially when large quantities are required. Overall, steel coils are distinguished by their exceptional strength, durability, corrosion resistance, versatility, and affordability. These qualities make steel coils the preferred choice for a wide range of industries, including construction, manufacturing, transportation, and energy.

- Q: What are the factors affecting the corrosion resistance of steel coils?

- The factors affecting the corrosion resistance of steel coils include the chemical composition of the steel, the presence of impurities or alloying elements, the surface condition and quality of the coils, the environmental conditions, such as humidity, temperature, and exposure to corrosive substances, and the presence of protective coatings or treatments.

- Q: What are the different methods of cutting edge trimming for steel coils?

- There exist multiple techniques for trimming steel coils, each with unique benefits and applications. Some of the frequently employed methods are as follows: 1. Shearing: This method entails cutting the steel coil's edge using sharp blades. It is a quick and efficient technique suitable for high-volume production. However, shearing may lead to slight distortion or burrs along the cut edge. 2. Slitting: Slitting involves passing the steel coil through rotating circular blades, resulting in narrower strips. This method is commonly adopted when precise width control is necessary, such as for the production of narrow strips or coils with multiple widths. 3. Laser cutting: Laser cutting is a highly precise technique that employs a laser beam to cut through the steel coil. It offers the advantage of producing clean and precise cuts without any distortion or burrs. Laser cutting is frequently used for intricate or complex shapes that require high accuracy. 4. Plasma cutting: Plasma cutting utilizes an ionized gas jet to cut through the steel coil. It is particularly suitable for thicker materials or applications where high cutting speeds are required. Plasma cutting can generate clean and smooth cuts, although a slight bevel may be present on the edge. 5. Waterjet cutting: Waterjet cutting employs a high-pressure jet of water mixed with an abrasive substance to cut through the steel coil. This technique is highly versatile and can be used for various materials and thicknesses. Waterjet cutting is renowned for producing precise cuts without any heat-affected zone. 6. Sawing: Sawing is a traditional method that involves using a rotating saw blade to cut through the steel coil. It is commonly used for thicker materials or when a rougher cut is acceptable. Sawing can be performed manually or with the assistance of automated sawing machines. Each method possesses its own advantages and considerations, and the selection depends on factors such as required accuracy, production volume, material thickness, and desired edge quality.

- Q: given the buoyant economic growth of india, what you guys think about steel industry? what can be the major issues in this industry in the coming days

- NAFTA became a unfastened commerce contract it is fairly a lot a republican proper. unfastened markets are a sturdy element. each and every so often unfastened markets deliver approximately the shortcoming of jobs in one sector yet that would not advise unfastened commerce is undesirable. opposition like that ensures that capital is spent in it is best way. Proping up death industries isn't a sturdy concept. i know it is not a favored element to declare, even though it is the certainty. would desire to we've propped up the horse and carriage marketplace while autos got here alongside so as that horse handlers did not lose thier jobs? in all risk not. unfastened commerce is a sturdy element. That being mentioned, i don't think of that Obama will merely blanketly wipe out any coverage by means of fact it became a Bush coverage. he isn't that stupid. If it became a sturdy coverage that labored, i'm particular it will be retained.

- Q: i got a strip of steel from lowes how to sharpen it its not that thick its kinda slim but its heavyish its around 4'2 feet tall i cant get a whetstone or anything elsei have a brick , sand paper , and a hammer and some charcoal i was heating it up and trying to pound a edge into italso how to cut the steel to make a pointy curved tip any help appreciated and please tell me easy methodsplus its not sharp at all

- Comp is right- Lowe's sold you mild steel. Good for a lot of things, but holding an edge isn't one. If you want to make some sort of edged tool, try something like Smokey Mountain Knife Works or another online vendor. They have better blades, even some Damascus blades which will hold an edge much better. If you want to make your own blades, you'll need to start with better steel and build your own forge. I made one from a brake drum and a vacuum with a dimmer switch. You'll also need an anvil, something that may be a bit tough to locate. A couple of hammers and you can start forging blades. For something simpler, locate a place where you can learn blacksmithing and forging. Some art classes teach this at a community college, but not many. Check the site below and see if you can go with ABANA. ... Good luck!!

- Q: How do steel coils contribute to the automotive aftermarket?

- The automotive aftermarket heavily relies on steel coils to manufacture a wide range of automotive parts and components. This secondary market deals with the sale of vehicle parts, accessories, and services after the initial purchase of the vehicle. Steel coils find their application in the production of several automotive aftermarket products, including springs, suspension components, chassis parts, and body panels. These coils are typically made from top-notch steel alloys that possess the desired characteristics of strength, durability, and performance. Springs are one of the primary uses of steel coils in the automotive aftermarket. These coiled springs play a crucial role in various automotive systems like suspension, brakes, and clutches. They provide the necessary support, stability, and shock absorption to ensure smooth and safe vehicle operation. Not only that, but steel coils also contribute to the manufacturing of chassis parts, which are vital for maintaining the vehicle's structural integrity and safety. Chassis parts made from steel coils include frame components, cross members, and reinforcement panels, which greatly enhance the overall stability and durability of the vehicle. Moreover, steel coils are extensively utilized in the production of body panels, such as doors, hoods, fenders, and roofs, which are commonly replaced or customized in the automotive aftermarket. These body panels, manufactured from steel coils, not only enhance the vehicle's aesthetics but also provide protection and resistance against impacts. In conclusion, steel coils play a critical role in the automotive aftermarket by facilitating the production of various parts and components necessary for vehicle repair, customization, and improvement. Their high strength, durability, and versatility make them an indispensable raw material, perfectly meeting the demanding requirements of the automotive industry.

- Q: What are the current trends in the steel coil industry?

- Some current trends in the steel coil industry include an increased focus on sustainability and environmental impact, the adoption of advanced technologies for improved efficiency and productivity, growing demand for high-strength and lightweight steel coils for automotive and construction sectors, and the emergence of new markets in developing countries. Additionally, there is a shift towards digitalization and automation in order to streamline operations and reduce costs.

- Q: How do steel coils contribute to strength and durability in manufacturing?

- Steel coils contribute to strength and durability in manufacturing in several ways. Firstly, steel is an inherently strong material due to its high tensile strength, which allows it to withstand heavy loads and resist deformation. When steel is coiled, it undergoes a process called hot rolling or cold rolling, which further enhances its strength and durability. During hot rolling, the steel is heated to high temperatures and then passed through a series of rollers, which compress and shape it into a coil. This process aligns the grain structure of the steel, making it more uniform and reducing internal stresses. The result is a stronger and more resilient material that can withstand the rigors of manufacturing processes such as bending, stamping, and forming without losing its structural integrity. Cold rolling, on the other hand, involves passing the steel through rollers at room temperature. This process not only increases the strength and hardness of the steel but also improves its surface finish. Cold-rolled steel coils are known for their smooth and uniform appearance, making them ideal for applications where aesthetics are important. Furthermore, steel coils can be coated with various protective layers to enhance their durability. These coatings, such as zinc or polymer-based coatings, act as barriers against corrosion, moisture, and other environmental factors that can weaken the steel. By preventing rust and degradation, these coatings extend the lifespan of steel coils and the products they are used in, making them more durable and cost-effective in the long run. In summary, steel coils contribute to strength and durability in manufacturing by providing a strong and resilient material that can withstand heavy loads and resist deformation. The hot rolling and cold rolling processes further enhance the strength and uniformity of the steel, while protective coatings help to prevent corrosion and extend the lifespan of the coils. Overall, steel coils are essential components in manufacturing that contribute to the strength and durability of a wide range of products.

- Q: How do steel coils compare to other materials?

- There are multiple advantages to using steel coils instead of other materials. Firstly, steel is renowned for its strength and durability, which makes steel coils highly resistant to wear and tear. This quality allows them to be used in a wide range of applications. Additionally, steel coils have excellent heat resistance, making them ideal for high-temperature environments. Furthermore, steel coils offer superior corrosion resistance compared to many other materials. This is especially important in industries like construction and automotive, where exposure to moisture and chemicals is common. Steel coils can withstand these harsh conditions, ensuring long-lasting performance and reliability. Another benefit of steel coils is their versatility. Steel can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. As a result, steel coils are suitable for a wide range of applications in manufacturing, construction, transportation, and energy industries. Moreover, steel coils provide good value for money. Despite their numerous benefits, steel coils are generally more affordable than materials like aluminum or copper. This makes steel coils a cost-effective choice for businesses and industries seeking high-quality and reliable materials. In summary, steel coils offer multiple advantages over other materials. They possess high strength, durability, and heat resistance, along with superior corrosion resistance. Steel coils are also versatile and easily customizable for different applications. Additionally, they provide good value for money. Overall, steel coils are a dependable and efficient option for various industries and applications.

Send your message to us

HOT- DIP Galvanized Steel Coils Regular 1000mm 1250mm Z60-Z120 Dx51d+Z, DC01

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords