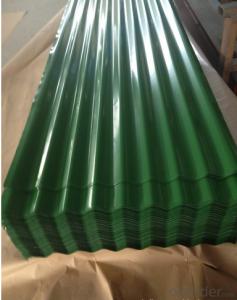

Hot DIP Galvanized Steel Coils Regular 1000mm 1219mm 1250mm Z60-Z120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Type:Steel Coil

Technique:Cold Rolled

Standard:ASTM, AISI, GB, JIS, DIN, BS

Surface Treatment:Galvanized

Special Use:Wear Resistant Steel

Application:Ship Plate, Boiler Plate, Container Plate, Flange Plate

Steel Thickness:0.12-3mm

Width:300 to 1500

Export Markets:Global

Additional Info.

Packing:Standard Package

Standard:PRIME

Production Capacity:10000 Tons Per Month

Product Description

Description:

EN 10147 Structure hot dip galvanized steel coil S250GD+Z, S350GD+Z (SGC340, SS275, SS340)/Custom Deep drawing hot dip galvanized steel coil DX52D+Z, DX53D+Z, S

Galvanized steel is taken cold rolled steel as the base metal, after continuous hot dip galvanizing process, the product produced is an excellent resistance to atmospheric corrosion coating steel coil, as the steel gets coated in layers of zinc and rust won't attach this protective metal

For countless outdoor, marine, or industrial applications, galvanized steel is an essential fabrication component. Hot dip galvanized steel is used in applications where steel may be exposed to weather, but where stainless steel is too expensive.

Application:

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

| andard | EN 10142 EN 10147 | DX51D+Z, DX52D+Z, DX53D+Z SS250GD+Z, SS350GD+Z |

| JIS G3321 | SGCC, SGCD, SGCDD, SGC400 | |

| ASTM A792M | CS type C, CS type B, DS, SS250 | |

| Base Metal | Cold rolled steel coils SPCC, SPCD, SPCE, DC01, DC03, DC04, CS, DS, DDS, Q195, Q250, Q350 | |

| Thickness | 0.14mm-3.0mm | |

| Width | 600mm-1600mm | |

| Coil ID | 508mm, 610mm | |

| Zinc coating | 60g/m2-450g/m2 | |

| Surface treating | chromium free passivation, chromium passivation, fingerprint resistant, oiled | |

| Spangle types | Minimal spangle, zero spangle, regular and big spangle | |

- Q: Are steel coils used in HVAC systems?

- Yes, steel coils are commonly used in HVAC systems. They are typically used in the construction of heating and cooling coils, which play a crucial role in the heat transfer process to provide conditioned air for buildings. Steel coils are used for their durability, thermal conductivity, and ability to withstand high temperatures and pressure.

- Q: Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- This Site Might Help You. RE: what is the elastic limit of steel in Nm^2? Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- Q: I had heard of steel braided fuel lines but ive also seen some air and coolant lines that are steel braided. Are these commonly used? I guess what I'm asking is if its a good idea to use them.

- Steel braided line are mainly use in turbulence areas, where they need to be protected. i would recommend replacing your brake line with it but not your coolant or air lines. there are other materials that are well suitable for coolant and air lines.

- Q: pros and cons of stainless steel and carbon steel swords

- Well generally Stainless steel blades are machine made and are of a display quality.. so expect looks, but don't expect quality or functionality from one. From carbon steel, I'd say you'd be looking at swords for practitioners of a sword art, reenactment, and collector quality blades. Stainless Steel Pros: Good for short blades like kitchen knives, cheap, won't easily rust or corrode. Cons: Long blades like swords become increasingly brittle and can snap with light use, most lack actual tangs(part of the blade that keeps the blade in the handle.) and are just welded onto a wire that[if broken} will send the blade out like a missile when swung, these are cheap display quality only. Carbon Steel Pros: Are usually much stronger and of a higher quality than their stainless counterparts, are often handmade by professional sword-smiths, no two blades are alike, fully functional work of art. Cons: Requires responsible care and maintenance, will corrode and rust easier, can be much more expensive.

- Q: How can the outer diameter and weight of steel coil be converted?

- To obtain the outer diameter of the steel coil is calculated according to the density of 7850, according to the density, in general, hot-rolled is 0. 96~0, 98, cold rolled, according to 0. 98~0. Ninety-nine

- Q: How much do steel coils weigh?

- The weight of steel coils can vary depending on several factors such as the thickness, width, and length of the coil, as well as the specific type of steel being used. Generally, steel coils can weigh anywhere from a few hundred pounds to several tons. It is important to note that steel coils are typically measured in terms of their weight per unit area, known as the coil's "basis weight" or "coil weight".

- Q: What are the challenges in coil slitting?

- Coil slitting, a method used to divide large metal coils into narrower strips of desired widths, has its advantages in terms of efficiency and flexibility. However, it also comes with several challenges. One of the primary obstacles in coil slitting is the need to ensure consistent strip width accuracy. To achieve this, it is crucial to maintain uniform width measurements throughout the process. Any deviation in strip width can have downstream effects on the production line, impacting the quality and functionality of the final product. Overcoming this challenge requires the use of precise slitting equipment and careful monitoring of process parameters. Another challenge lies in managing the quality of the strip edges. The edges of the slit strips play a critical role, particularly in applications where they must be free from imperfections like burrs. Attaining clean and smooth edges necessitates proper blade selection, positioning, and maintenance. Any defects or irregularities on the strip edges can affect subsequent processes such as bending, welding, or coating. Additionally, the type of material being slit can pose challenges. Certain metals, such as high-strength steels or alloys, may be more difficult to cut due to their hardness or brittleness. Slitting these materials can result in blade wear and premature failure, leading to increased downtime and maintenance costs. Moreover, the presence of contaminants or surface defects on the coil can also impact the slitting process, requiring additional cleaning or preparation steps. Handling and processing large coils present another significant challenge. Coils can be cumbersome and heavy, necessitating proper equipment and procedures to ensure safe handling. Furthermore, the slitting process generates a significant amount of scrap material, which needs to be efficiently managed and disposed of. Proper storage, transportation, and recycling of the scrap are essential to minimize waste and maintain a clean and organized working environment. In conclusion, coil slitting offers benefits in terms of customization and productivity. However, it also poses challenges in maintaining strip width accuracy, managing edge quality, dealing with difficult materials, and handling large coils and scrap. Overcoming these challenges requires expertise, precision equipment, and careful process control to ensure the desired quality and efficiency in coil slitting operations.

- Q: Is steel cut really better? The nutritional profiles are nealy identical. Which one has the best flavor??Thanks!

- Steel cut oats taste the best but rolled oats will do just fine too.

- Q: What is the maximum length of a steel coil?

- The maximum length of a steel coil can vary depending on various factors such as the type of steel, manufacturing capabilities, and transportation logistics. However, in general, steel coils can be several hundred meters long, with some specialty coils exceeding a kilometer in length.

- Q: How are steel coils used in the manufacturing of solar panels?

- Steel coils are commonly used in the manufacturing of solar panels to provide structural support and stability. These coils are typically used to create the framework of the solar panel, ensuring that it remains rigid and durable. Additionally, steel coils can be used to create the mounting structures that hold the solar panels in place, allowing for easy installation and maintenance.

Send your message to us

Hot DIP Galvanized Steel Coils Regular 1000mm 1219mm 1250mm Z60-Z120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords