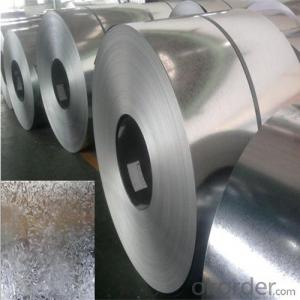

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | China (Mainland) | Brand Name: | N/M | Model Number: | ssp-226 |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: How are steel coils used in the production of agricultural systems?

- Due to their durability and strength, steel coils are frequently employed in the production of agricultural systems. Specifically, these coils are commonly utilized in the creation of machinery and equipment essential for agricultural operations. One prevalent use of steel coils lies in the manufacture of farming machinery such as tractors, plows, and cultivators. These machines necessitate robust components capable of enduring the challenging conditions present in the agricultural environment. Steel coils are employed to fabricate the frames, chassis, and other structural parts of these machines, providing the necessary strength and support. Additionally, steel coils are employed in the creation of irrigation systems, which play a crucial role in efficient water management within agriculture. These coils are employed in the construction of pipes, valves, and fittings, ensuring the durability and long-lasting nature of the irrigation system. Furthermore, steel coils are employed to fabricate storage tanks and silos, which serve as vital tools for storing and preserving agricultural products like grains, seeds, and fertilizers. Moreover, steel coils find application in the construction of greenhouses and agricultural buildings. These coils are used to fabricate the structural framework, providing stability and resistance against environmental factors. Steel coils are also employed in the production of fencing and enclosures to safeguard crops and livestock from external threats. In conclusion, steel coils play a significant role in the production of agricultural systems by delivering the necessary strength, durability, and stability required for farming machinery, irrigation systems, storage facilities, and agricultural structures. Their utilization ensures that these systems can withstand the demanding conditions of the agricultural industry and contribute to efficient and sustainable farming practices.

- Q: How do steel coils contribute to the agricultural sector?

- The agricultural sector benefits greatly from the use of steel coils in various ways. To begin with, these coils are instrumental in the production of agricultural machinery and equipment such as tractors, harvesters, and irrigation systems. These machines are indispensable for carrying out farming operations efficiently, thereby helping farmers increase productivity and cut down on labor costs. The robustness and durability of steel coils ensure the machinery's ability to endure the harsh conditions of the agricultural environment. Furthermore, steel coils find application in the construction of storage facilities and warehouses for agricultural products. To safeguard crops from damage, these structures must be strong and resistant to external elements. Steel coils provide the required strength and stability for the construction of such storage facilities, thereby ensuring the secure storage of agricultural produce. In addition, steel coils are employed in the fabrication of fencing and other agricultural infrastructure. Fencing is of utmost importance in protecting crops from animals and trespassing. Steel coils serve as a robust material for fencing, guaranteeing the security and protection of agricultural lands. Moreover, steel coils are utilized in the manufacture of irrigation pipes and systems. Efficient irrigation is crucial for the growth and yield of crops, particularly in areas with limited water resources. Steel coils are used to create pipes capable of withstanding high pressure and resistant to corrosion, thereby ensuring the effective distribution of water throughout agricultural fields. In conclusion, steel coils play a vital role in the agricultural sector, providing the necessary materials for manufacturing machinery, constructing storage facilities, fencing, and irrigation systems. The strength, durability, and resistance to harsh conditions make steel coils an essential component in enhancing agricultural productivity, protecting crops, and ensuring efficient farming practices.

- Q: What are the different methods of perforating steel coils?

- Various techniques are employed to perforate steel coils, each possessing unique merits and applications. 1. Mechanical Punching: One frequently employed method for perforating steel coils is mechanical punching. This involves utilizing a mechanical press, punch, and die set to puncture holes in the coil. Customization of hole size and shape is achievable by designing the punch and die set accordingly. Mechanical punching is efficient and generates consistent results, producing high-quality holes. 2. Laser Cutting: For intricate designs or complex hole patterns, laser cutting is a sought-after technique to perforate steel coils. A powerful laser beam is employed to precisely and cleanly cut through the coil, creating holes. Hole size, shape, and spacing flexibility are offered by laser cutting, which can be computer-controlled for precise and repeatable outcomes. 3. CNC Plasma Cutting: This method leverages a high-velocity plasma jet to cut through the steel coil and create perforations. CNC technology guides the plasma cutter, ensuring precise and accurate hole patterns. CNC plasma cutting is ideal for thicker steel coils and can generate larger holes compared to laser cutting. 4. Waterjet Cutting: The use of a high-pressure jet of water mixed with an abrasive substance characterizes waterjet cutting for perforating steel coils. This technique allows versatility in terms of hole dimensions, shapes, and compatibility with different materials. Waterjet cutting is renowned for its capability to produce intricate and precise perforations without causing heat-affected zones or distortion. 5. Electrical Discharge Machining (EDM): EDM is an approach that employs electrical discharges to erode the material, forming perforations in the steel coil. It involves the use of a conductive electrode and dielectric fluid to generate controlled sparks, removing material and creating holes. EDM is suitable for creating complex shapes and patterns, particularly on hard materials. The choice of method depends on various factors, including desired hole size and shape, steel coil thickness and type, required precision, and production volume. Each method has its own strengths and limitations, necessitating the selection of the most appropriate technique based on the specific requirements of the perforated steel coils.

- Q: ok I got a dpms ar 15 and all i have put though it is good brass 223 ammo but is it ok to shoot the old crappy steel cased wolf ammo out of it will it hurt its function or will it hurt it cosmetically?

- The Wolf ammo and the rest of its ilk also has steel bullet jackets, so it will wear your barrel faster than copper jacketed ammo. Plus you can't reload it. I've also seen a few manufacturers say not to use it as pressures may be erratic. I wouldn't buy it to shoot unless I was shooting it in someone else's rifle, I would buy it to stash though.

- Q: How are steel coils used in the manufacturing of cables?

- Steel coils are used in the manufacturing of cables as the core material around which the cable is wrapped. The high tensile strength of steel provides durability and stability, allowing the cable to withstand tension and pressure. The steel coils also help in preventing the cable from stretching or bending excessively, ensuring its structural integrity.

- Q: They are showing on tv a special on how the new World Trade Center, building 1, is being built. Focusing on the steel and the guys fitting everything together.Where do builders go to buy all that steel framing? We do not build really tall buildings where I live so most of the steel is cut and welded on the job site. At World Trade Center 1, they seem to get the steel on trucks; already cut and welded.

- Most of the parts are cut, welded, and fabricated indoors in a welding shop at another location. Then they're trucked to the site and simply need to be bolted together. This is made possible through the use of computer aided design and modeling programs, so that parts can be made to fit almost presciently in the field. They buy the steel from steel companies. I couldn't tell you exactly where it comes from, you'd have to ask the contractors themselves.

- Q: How are steel coils used in the production of automotive parts?

- Steel coils are used in the production of automotive parts as they provide a durable and flexible material for making various components such as body panels, chassis, and suspension parts. The coils are processed through specialized machinery to cut, shape, and form the steel into the required parts, ensuring strength and precision. Additionally, the coils can be treated or coated to enhance corrosion resistance, further improving the longevity and performance of automotive parts.

- Q: How are steel coils used in the production of shelving units?

- Steel coils are used in the production of shelving units by being processed and formed into various components such as shelves, brackets, and support beams. These coils are typically cut, bent, and welded to create the necessary shapes and sizes required for the shelving unit. The steel material provides strength and durability to the shelves, ensuring they can hold heavy items and withstand the weight placed on them.

- Q: Steel being my favorite type, I just picked up Heart Gold today, my gf got Soul Silver...I was wondering which steel types are available and somewhat easily obtainable in HG (and/or what is the earliest steel type I can get?)

- Magnemite is the first steel type you can obtain. Get it by going to the Safari Zone in the mountain area. Magnetons are also found there. You can also evolve a Pineco into a Forretress. You can find Pineco by headbutting trees. Unfortunately, those are the only easy-to-find steels before the Pokemon league. Afterwards, you can obtain a Bronzor, Metagross, Steelix*, and Scizor*. Your girlfriend can trade you a Skarmory as well. Of all the ones listed, Forretress is probably the easiest to obtain, but Metagross is the best. I hope that helped. Contact me if you want more info! *Steelix and Scizor are obtained by trading an Onix or Scyther while holding a Metal Coat. Technically, you can get them before the Elite Four. However, you would need a friend to give you their Metal Coat, or get lucky and find one on a wild Pokemon, becaue the only one you get in-game is obtained after you beat the Elite Four.

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils include assessing the extent of the damage, ensuring proper storage conditions, using appropriate lifting equipment, and implementing safety measures to prevent injuries or further damage. It is crucial to follow manufacturer recommendations and consult with experts in the field for specific guidelines based on the type and severity of the damage.

Send your message to us

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords