Hot-Dip Galvanized Steel Coil Used for Industry with Our Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

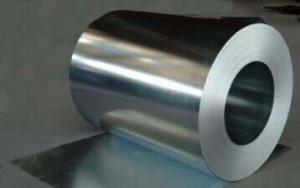

The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

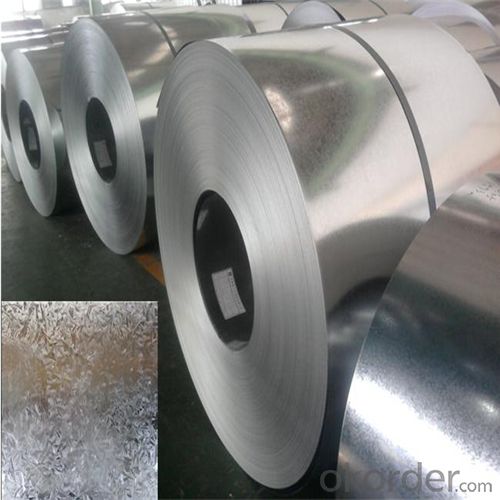

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

- Q: How are steel coils used in the packaging industry?

- Steel coils are used in the packaging industry to create sturdy and durable packaging materials, such as metal drums, cans, and containers. The coils are unwound and shaped into the desired form, providing a strong and protective barrier for various products during storage and transportation.

- Q: How are steel coils used in the production of oil and gas equipment?

- Steel coils are used in the production of oil and gas equipment primarily for their strength, durability, and corrosion resistance. These coils are utilized to manufacture various components such as pipes, valves, fittings, and storage tanks that are required in the exploration, drilling, and transportation of oil and gas.

- Q: What is stainless steel coil used for?

- Stainless steel coil is highly valued in numerous industries for its long-lasting nature, ability to resist corrosion, and attractive appearance. One of its most frequent uses occurs in the manufacturing and construction fields, where it is employed in the creation of a wide array of products such as kitchen appliances, cutlery, automotive components, and architectural structures. Its resistance to corrosion makes it especially suitable for applications that necessitate protection against moisture, chemicals, and harsh environmental conditions. Moreover, the strength and ability to withstand high temperatures make stainless steel coils well-suited for use in industrial equipment, heat exchangers, and piping systems. Furthermore, the sleek and contemporary look of stainless steel is often preferred in the design and production of consumer goods like furniture, jewelry, and decorative items. In summary, stainless steel coil is a versatile material that is extensively utilized in a variety of industries due to its exceptional mechanical properties, ability to resist corrosion, and its versatility in terms of appearance.

- Q: What are the factors affecting the price of steel coils?

- There are several factors that can affect the price of steel coils. These include the cost of raw materials used in the production of steel, such as iron ore and coal. Additionally, the global supply and demand for steel can also impact prices. Other factors can include currency exchange rates, trade policies, transportation costs, and market competition. Overall, the price of steel coils is influenced by a combination of economic, environmental, and geopolitical factors.

- Q: How are steel coils used in the production of steel latches?

- Steel coils are used in the production of steel latches as they serve as the raw material for manufacturing these components. The coils are processed through various manufacturing steps, such as cutting, stamping, and forming, to shape them into the desired latch design. These transformed steel coils are then further treated with coatings or finishes to enhance their durability and corrosion resistance. Ultimately, steel coils play a crucial role in providing the base material necessary for creating sturdy and functional steel latches.

- Q: This needs to be in a percentage by mass. Could you please also reference where this info has come from. Thanks.

- Steel is almost all elemental Iron (Fe) with a small percentage of carbon (about 0.2 percent) and other alloying metals if required. Iron as in cast iron just has more carbon which lowers the melting point to where it can be cast with lower technology (it was discovered first). Bessemer developed a process to remove most of the carbon and increase the furnace heat, resulting in a tougher metal called steel.

- Q: What are the different methods of edge trimming steel coils?

- Manufacturers have various methods at their disposal for edge trimming steel coils, which are chosen based on their specific preferences and requirements. Some commonly used methods include: 1. Slitting: This method involves passing the coil through rotating circular blades to precisely cut the edges. It is suitable for different thicknesses of steel coils. 2. Milling: By using milling cutters, excess material is removed to achieve the desired edge finish. Milling is often employed for thicker steel coils or when a specific edge profile is needed. 3. Shearing: A sharp blade is used to cut the steel coil along a straight line, providing a clean and straight edge. This method is commonly used for thinner steel coils. 4. Laser cutting: Edge trimming is achieved by utilizing a focused laser beam to melt or vaporize the excess material, resulting in a precise and smooth edge. Laser cutting is often preferred for thinner gauges or when intricate shapes or patterns are necessary. 5. Water jet cutting: This method involves a high-pressure stream of water mixed with abrasive particles to trim the edges of the steel coil. Water jet cutting offers a versatile and precise cutting solution, particularly for thicker steel coils and complex shapes. Manufacturers should carefully assess their specific requirements, including coil thickness, desired edge finish, speed, and cost, to choose the most suitable edge trimming method for their steel coils.

- Q: I bought my Gerber Scout for 29 bucks at the local Walmart a couple months ago, and so far it's performed better than any of my previous knives (a couple of low quality Bucks, and a Winchester). However, my friend just bought a 50 dollar Buck knife and I absolutely love it, so I'm debating trading mine in and pitching in a bit of cash for the same kind.What troubles me is the fact that everybody seems to be bashing 440A steel. I hear a lot of bad things about it; how it is soft, chips easy, dull quickly, etc. How bad is 440A steel really, and would it be worth trading in my Gerber plus about 30 cash for a Buck Vantage Pro? Apparently the Vantage Pro uses S30V steel, so is it really that big of an upgrade, from 440A to S30V? Thank you.

- Its the standard for most knives and its the easiest to sharpen, I have a couple 440 steel knives and they have never failed me, my oldest one is 11 years old and I have stabbed multiple people(in self defense, cut open backpacks, seat belts, fishing string, limes, thin rope, jeans, jackets, pockets, seats, popped tires, moved hot charcoal and other stuff, it just has to be sharpened every now and then. Although I really like carbon knives like KA-BAR's those are amazing and are the only fixed blade knife I would ever buy.

- Q: What are the different types of steel coil surface finishes?

- There exist various options for steel coil surface finishes, each possessing distinct characteristics and uses. Some of the most frequently seen types are as follows: 1. Hot rolled: Achieved by subjecting the steel to high temperatures, resulting in a rough and textured surface. Hot rolled steel coils are commonly employed in applications where aesthetics are not a priority, such as structural or industrial projects. 2. Cold rolled: In contrast to hot rolled steel, cold rolled steel coils are processed at lower temperatures, resulting in a smoother and more refined surface. This finish is suitable for applications where a clean and polished appearance is desired, such as automotive parts, appliances, and furniture. 3. Galvanized: These steel coils are coated with a layer of zinc to safeguard against corrosion. This finish provides excellent rust resistance and can be utilized in various outdoor applications, including roofing, fencing, and signage. 4. Stainless steel: Stainless steel coils possess a unique finish that is resistant to corrosion, staining, and rust. Due to this, they find great versatility and suitability across a wide range of applications, including kitchen appliances, medical equipment, and architectural projects. 5. Coated: Coated steel coils are treated with a protective layer of paint or other coatings to enhance durability and aesthetic appeal. This finish is commonly employed in the construction industry for applications such as roofing, siding, and garage doors. 6. Pre-painted: Before being formed into the final product, pre-painted steel coils are coated with a layer of paint or resin. This finish offers a wide range of colors and finishes, making it popular for applications such as building cladding, appliances, and automotive parts. In summary, the selection of a steel coil surface finish relies on the specific requirements of the project, including aesthetics, corrosion resistance, and durability. Each finish has its own advantages and disadvantages, and it is crucial to consider these factors when choosing the appropriate type of steel coil surface finish for a particular application.

- Q: How are steel coils weighed?

- Steel coils are typically weighed using industrial weighing scales or load cells. These devices are capable of accurately measuring the weight of the coils, whether they are small or large in size. The coils are placed on the scale or load cells, and the weight is digitally displayed or recorded for further analysis or documentation.

Send your message to us

Hot-Dip Galvanized Steel Coil Used for Industry with Our Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords