Hot-dip Aluzinc Steel from High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

4)Farm: barn, sheds, silos, piping and other greenhouse.

5)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

• High temperature oxidation resistance

• Excellent corrosion resistance

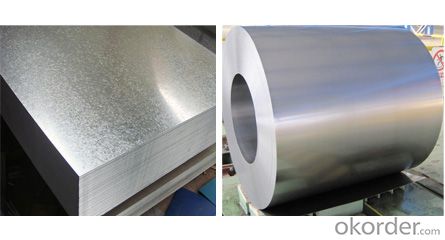

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

Available Specification

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the production of kitchen appliances?

- Steel coils are used in the production of kitchen appliances as they are transformed into various components such as panels, doors, and frames. These coils are typically cut, shaped, and welded into desired forms, providing strength, durability, and a sleek finish to the appliances.

- Q: What are steel coils?

- Steel coils are large, flat sheets of steel that have been rolled into a circular shape. They are commonly used in various industries, including automotive, construction, and manufacturing, for purposes such as making pipes, tubes, and sheet metal products.

- Q: What are the dimensions of steel coils used in the automotive industry?

- The dimensions of steel coils used in the automotive industry can vary depending on the specific application and requirements. However, typical dimensions for steel coils used in the automotive industry range from 0.5mm to 3mm in thickness and from 500mm to 2000mm in width. The length of the coils can vary depending on the production process and customer specifications. Additionally, the weight of the coils can range from a few hundred kilograms to several tons. It is important to note that these dimensions are general guidelines and can vary depending on the specific needs of the automotive manufacturer.

- Q: How are steel coils used in the manufacturing of automotive chassis?

- Steel coils are used in the manufacturing of automotive chassis as they provide the necessary strength and durability required to support the vehicle's structure. These coils are used to form various components of the chassis, such as frame rails, cross members, and suspension mounts, ensuring optimal stability and safety of the vehicle.

- Q: How are steel coils inspected for weldability using welding tests?

- Steel coils can be inspected for weldability using various welding tests. One common method is the bend test, where a sample of the coil is bent to evaluate the ductility and resistance to cracking. Another test is the tensile test, which measures the strength and elongation of the steel under tension. Additionally, the charpy impact test assesses the steel's toughness by measuring its ability to absorb energy during impact. These tests help determine the suitability of the steel coils for welding applications and ensure the quality of the welds.

- Q: Steel steps steel guard rail steel chair. You see where I'm going with this.

- The guard rails have to be steel or fans would tear them apart. The steps have to be steel..( although they are not 'solid steel'), in order to hold all that weight of people going up and down them for an entire show. The chairs are very forgiving. All in all, I can see where you are going with this, however it has been this way for decades now. Notice there are no steel tables or steel announcers desks?

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are processed and shaped into long sections known as rails. These coils are first uncoiled and then heated, allowing them to be rolled and formed into the desired rail shape. The resulting rails are then cut to the required length and undergo further processes such as straightening and finishing to ensure their strength, durability, and suitability for use in railways.

- Q: How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils are both widely used in various industries for their strength and durability. However, there are some key differences between the two that should be considered when choosing the appropriate material for a specific application. One of the main distinctions between steel coils and stainless steel coils is the composition of the materials. Steel coils are made primarily of iron and carbon, with other elements added to enhance specific properties. On the other hand, stainless steel coils are made of iron, carbon, and a significant amount of chromium, which gives them their unique corrosion-resistant properties. Due to the presence of chromium, stainless steel coils offer superior resistance to corrosion, tarnishing, and rust compared to regular steel coils. This makes stainless steel coils particularly suitable for applications in environments with high humidity, moisture, or exposure to corrosive substances. In contrast, steel coils are more prone to rust and may require additional protective coatings or treatments to prevent corrosion. Another significant difference is the appearance of the two materials. Stainless steel coils have a shiny and reflective surface, giving them an aesthetically pleasing look. They are commonly used in applications where appearance is important, such as kitchen appliances, architectural structures, or decorative purposes. Steel coils, on the other hand, have a matte or dull finish and are often used in industrial applications where appearance is not a primary concern. In terms of strength, both steel and stainless steel coils offer excellent mechanical properties. However, stainless steel coils generally exhibit higher tensile strength and greater resistance to high temperatures. This makes them suitable for applications that require strength, such as construction, automotive, or aerospace industries. Lastly, cost is a factor that should be considered when comparing steel coils to stainless steel coils. Steel coils are generally more cost-effective than stainless steel coils due to the lower cost of raw materials and simpler manufacturing processes. However, when the added value of corrosion resistance and longevity is taken into account, stainless steel coils may prove to be a more economical choice in the long run, as they require less maintenance and replacement. In conclusion, steel coils and stainless steel coils have different properties and characteristics that make them suitable for specific applications. Stainless steel coils offer superior corrosion resistance, a shiny appearance, and higher tensile strength, while steel coils are more cost-effective. The choice between the two ultimately depends on the specific requirements of the application, such as the environment, aesthetics, strength, and budget.

- Q: Corten steel tends to overheat in hot environments? (for example copper heats up under the sun)

- Bill summed it up pretty quick and provided a link. For some reason you are focusing on the copper content when it really is insignificant in the overall picture of the sun hitting its surface. If you could elaborate more, maybe we could offer a better answer.

- Q: What are the different methods of coil flattening for steel coils?

- Coil flattening for steel coils can be achieved through various methods, each having its own advantages and limitations. Some commonly employed techniques are as follows: 1. Roller leveling: By passing the steel coil through a series of rollers that exert pressure, this method flattens the coil. The rollers can be adjusted to achieve the desired level of flatness. Roller leveling is a versatile approach capable of handling a wide range of coil sizes and thicknesses. 2. Precision leveling: This method employs a more advanced leveling machine that applies pressure to specific areas of the coil to eliminate any waviness or defects. Precision leveling is commonly used for high-quality steel coils that require exceptionally flat surfaces. 3. Stretch leveling: Also known as tension leveling, this technique involves stretching the steel coil beyond its yield point, causing permanent deformation and flattening. Stretch leveling is frequently used for thinner gauge coils and effectively eliminates coil set and crossbow defects. 4. Temper rolling: This method subjects the steel coil to a controlled low-temperature heat treatment followed by cold rolling. The combination of heat and cold rolling helps relieve internal stresses and improve flatness. Temper rolling is particularly suitable for coils that require enhanced surface quality. 5. Laser flattening: This advanced method utilizes laser technology to selectively heat and flatten specific areas of the coil. Laser flattening is highly precise and capable of correcting localized defects or unevenness. However, due to its higher cost, it is typically used for smaller coils. It is essential to consider various factors, such as desired flatness requirements, coil dimensions, material properties, and production budget, when selecting the most appropriate coil flattening method.

Send your message to us

Hot-dip Aluzinc Steel from High Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords