All Categories

- - Steel Wire Rod

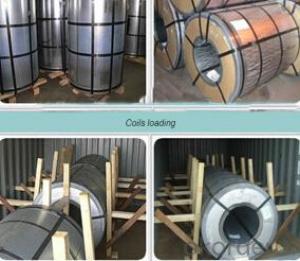

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do steel coil properties change when used in the aerospace industry for aircraft components and structural members?

When steel coils are used in the aerospace industry for aircraft components and structural members, their properties undergo significant changes. Firstly, the steel undergoes rigorous testing and quality control to ensure it meets the stringent standards required for aerospace applications. This includes testing for strength, durability, and resistance to extreme temperatures and corrosion.

Additionally, the steel is often subjected to various treatments and processes such as heat treatment, surface coating, and precision machining to enhance its mechanical properties and performance. These processes aim to increase the strength-to-weight ratio, improve fatigue resistance, and enhance the material's ability to withstand high stress and impact loads.

Furthermore, the steel coils used in the aerospace industry are typically manufactured to precise specifications, ensuring consistency in dimensions and mechanical properties. This allows for better integration and compatibility with other aircraft components, leading to improved performance and safety.

In summary, when steel coils are employed in the aerospace industry for aircraft components and structural members, their properties are carefully optimized and tailored to meet the demanding requirements of the industry, resulting in enhanced strength, durability, and performance characteristics.

What are the innovations in coil processing technology for enhanced product quality and efficiency?

Some innovations in coil processing technology for enhanced product quality and efficiency include advancements in automation and control systems, precision leveling techniques, improved edge trimming methods, and enhanced material handling and transportation systems. These innovations help to optimize production processes, reduce material waste, enhance product consistency, and improve overall operational efficiency in coil processing industries.

How are steel coils inspected for surface defects in the production of metal containers?

Steel coils are inspected for surface defects in the production of metal containers using various techniques such as visual inspection, magnetic particle inspection, eddy current testing, and ultrasonic testing. These methods help to identify any surface abnormalities or defects on the steel coils, ensuring the production of high-quality metal containers.

What is the maximum coil weight for handling and transportation?

The maximum coil weight for handling and transportation depends on various factors such as the type of coil, the equipment being used, and the regulations in place. However, in general, coil weights typically range from a few hundred pounds to several tons.

Wholesale Steel Coils from supplier in Czech Republic

Our team of dedicated professionals is committed to providing excellent customer service and technical support throughout the entire procurement process. From initial inquiries and quotations to logistics and after-sales support, we ensure a smooth and efficient experience for our customers.

We understand that each project is unique, and we take pride in our ability to offer customized solutions. Our steel coil products are available in various grades, sizes, and finishes to meet the specific needs of different industries and applications. We work closely with our customers to understand their requirements and recommend the most suitable steel coils for their projects.

Furthermore, as a subsidiary platform of CNBM, we have access to a vast network of resources and expertise. CNBM is a Fortune Global 500 company with extensive experience in the steel industry. This allows us to leverage global best practices, cutting-edge technologies, and efficient supply chain management to deliver high-quality steel coils at competitive prices.

In conclusion, our company is your trusted partner for all your steel coil needs in the Czech Republic. With our comprehensive product range, market experience, and commitment to customer satisfaction, we are confident in our ability to exceed your expectations. Contact us today to discuss your requirements and let us help you achieve success in your projects.

We understand that each project is unique, and we take pride in our ability to offer customized solutions. Our steel coil products are available in various grades, sizes, and finishes to meet the specific needs of different industries and applications. We work closely with our customers to understand their requirements and recommend the most suitable steel coils for their projects.

Furthermore, as a subsidiary platform of CNBM, we have access to a vast network of resources and expertise. CNBM is a Fortune Global 500 company with extensive experience in the steel industry. This allows us to leverage global best practices, cutting-edge technologies, and efficient supply chain management to deliver high-quality steel coils at competitive prices.

In conclusion, our company is your trusted partner for all your steel coil needs in the Czech Republic. With our comprehensive product range, market experience, and commitment to customer satisfaction, we are confident in our ability to exceed your expectations. Contact us today to discuss your requirements and let us help you achieve success in your projects.