Hot-Dip Aluzinc Steel Coil Used for Industry with Our Good and High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Galvanized Steel Coil Used for Industry

1.Structure of Hot-Dip Galvanized Steel Coil Description

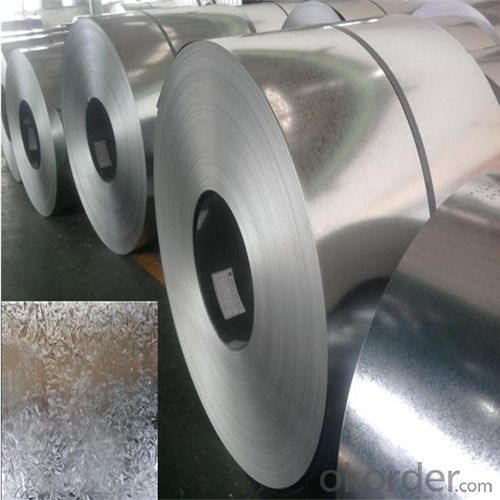

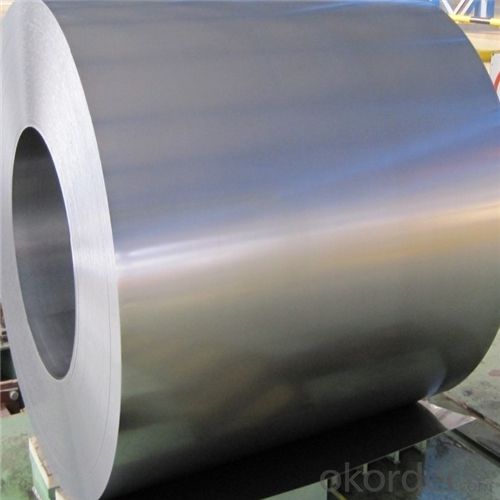

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful countless outdoor and industrial applications.

2.Main Features of the Hot-Dip Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Galvanized Steel Coil Images

4. Hot-Dip Galvanized Steel Coil Specification

Hot-Dip Galvanized Steel Coil | |

Thicknenss | 0.10mm-5.00mm |

Width | 2000mm max |

Coating mass | 30-600g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

We can supply galvanized corrugatedsheet with high quality and competitive price. Our corrugated board is a high strength, durable and generally used for a steel building decoration. As a result of high strength steel, plus a reasonable size design make it widely used in a variety of architectural roof, walls, easy installation, flexible, no building restrictions on any factors.

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

- Q: How are steel coils inspected for surface quality?

- To ensure that steel coils meet the required standards and are defect-free, a meticulous inspection process is carried out using various methods and technologies. The following steps are involved in inspecting the surface quality of steel coils: 1. Visual Inspection: Trained personnel visually examine the entire surface of the coils to detect any visible defects such as scratches, dents, or irregularities. This step allows for the identification of obvious issues through visual observation. 2. Magnetic Particle Inspection: This non-destructive testing method involves applying a magnetic field to the surface of the steel coil and then adding a magnetic particle solution. Any surface cracks or defects cause the magnetic particles to cluster, making them visible under appropriate lighting. This technique effectively detects surface cracks and abnormalities. 3. Eddy Current Testing: Electromagnetic induction is used in this inspection method to identify surface defects. An eddy current probe is moved over the surface of the steel coil, and any variations in the electrical current induced by the magnetic field are detected. This technique is especially useful for detecting surface cracks, pits, or corrosion. 4. Ultrasonic Testing: Ultrasonic waves are employed to inspect the surface of the steel coil for hidden defects like subsurface cracks or inclusions. High-frequency sound waves are transmitted into the material, and any changes in the reflected sound wave pattern indicate the presence of defects. Ultrasonic testing is highly reliable and can detect even the smallest defects within the steel coil. 5. Surface Roughness Measurement: Specialized equipment is used to measure the surface roughness of the steel coil. This measurement helps determine if the surface meets the required smoothness standards. The equipment scans the surface and provides detailed information about the roughness, allowing the inspector to ensure it falls within an acceptable range. In summary, the inspection of steel coils for surface quality involves a comprehensive process that combines visual examination with advanced testing methods such as magnetic particle inspection, eddy current testing, ultrasonic testing, and surface roughness measurement. These inspection techniques effectively identify and evaluate potential defects or surface irregularities, ensuring that the steel coils meet the necessary surface quality standards.

- Q: Should I stick with the all steel kit over the acrylic tapers and steel plugs? or would the acrylic be ok? I keep hearing that steel is the best and acrylic can cause problems. I just want to do it correctly and take my time with it, no rushing.thanks

- It depends on your body and what you prefer. If you body is allergic to one of them you would have to chose for another one. If it's not allergic to any, than you can use whatever you like the most, just try both.

- Q: Can steel coils be customized in terms of size and shape?

- Yes, steel coils can be customized in terms of both size and shape to meet specific requirements and applications.

- Q: A song by brokencyde is called Blue Steel.... a verse in it says Don't make me show you blue steel.

- Reference is to a gun which is typically the process of Bluing the steel of the guns metal parts.

- Q: How are steel coils used in the production of steel latches?

- Steel coils are used in the production of steel latches as they serve as the raw material for manufacturing these components. The coils are processed through various manufacturing steps, such as cutting, stamping, and forming, to shape them into the desired latch design. These transformed steel coils are then further treated with coatings or finishes to enhance their durability and corrosion resistance. Ultimately, steel coils play a crucial role in providing the base material necessary for creating sturdy and functional steel latches.

- Q: How are steel coils used in the manufacturing of springs?

- Steel coils are used in the manufacturing of springs by being formed into a helical shape, allowing them to store and release energy when subjected to force or pressure.

- Q: Are steel coils corrosion-resistant?

- Yes, steel coils can be made corrosion-resistant through various methods such as galvanization or coating them with protective layers.

- Q: who, when and where was dual phase steel invented?

- Looking okorder /... but I would note that this stuff seems an awful lot like the techniques that have been used for making high quality swords and cutting tools for thousands of years including the famed Damacas steel. In these, the steel is heated and slowly cooled (annealed) to produce the tough matrix, then the piece is reheated and quenched to produce the hard edge. What Dual-phase seems to do is bring the process to bulk manufacture.

- Q: What are the best types of steel for swords

- steel is the best material for a real sword

- Q: Can steel coils be coated with magnetic materials?

- Yes, steel coils can be coated with magnetic materials. The coating process typically involves applying a thin layer of magnetic material, such as nickel or zinc, to the surface of the steel coils. This coating enhances the magnetic properties of the steel, making it more suitable for specific applications that require magnetism.

Send your message to us

Hot-Dip Aluzinc Steel Coil Used for Industry with Our Good and High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords