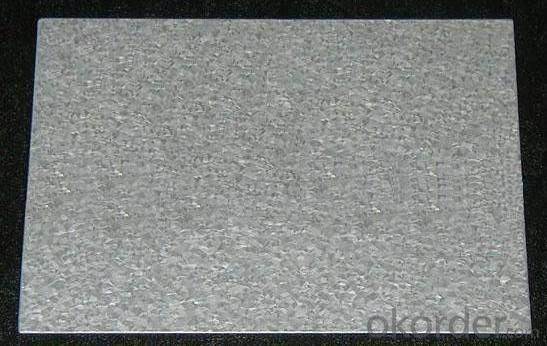

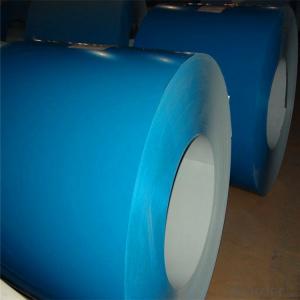

Hot-Dip Aluzinc Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluzinc Steel Coil

Steel Grade & Standard:G550

Spangle:Minimized Spangle

Aluzinc Coating Mass:AZ40

Surface Treatment:Chromated, Unoiled, NonSkinpassed, Anti-Finger Print

Size (MM) (BMT) MOQ (MTS)

0.23mm x 914 x C 60

0.25mm x 914 x C 60

0.28mm x 914 x C 60

0.30mm x 914 x C 60

0.35mm x 914 x C 60

0.40mm x 914 x C 60

0.45mm x 914 x C 60

Package Type: EYE TO SIDE

Thickness Tolerance:+/-0.01mm

Width Tolerance:0/+5mm

Quantity Tolerance: +/-10%

VALIDITY: 3 WORKING DAYSPAYMENT: T/T WITH 30% DOWNPAYMENT AND BALANCE AGAINST INVOICE & PACKING LISTSHIPMENT: 45 DAYS FOR CARGO READINESS AND 15 DAYS FOR CATCHING THE VESSEL

- Q: What is the average surface finish tolerance for steel coils?

- The average surface finish tolerance for steel coils can vary depending on the specific requirements and applications. However, commonly accepted standards for surface finish tolerance in the steel industry range between 10 to 20 microinches (0.25 to 0.5 micrometers).

- Q: So what's harder gold or steel

- steel. gold is pretty soft.

- Q: I just bought some cheap earrings from this beauty supply store but they said surgical steel So will they prevent my ears from bleeding / infection ?

- Surgical steel is a grade of steel often used in medical appliances like tweezers, forceps, etc. It's generally non-reactive and considered very safe. It doesn't contain any special properties against infection--you still have to observe basic hygiene and clean your piercings properly--but most people can wear surgical steel earrings without a problem. However, if you have a contact allergy to base metals like nickel, surgical steel may cause redness or irritation because of the metals used in it. If cheap rings or necklaces make your skin break out in a rash you should NOT wear surgical steel.

- Q: What are the common manufacturing defects in steel coils?

- Common manufacturing defects in steel coils include surface defects such as scratches, pits, and scale, as well as shape defects like buckling, waviness, and edge cracks. Additionally, internal defects such as voids, inclusions, and segregation may also be present in steel coils.

- Q: How are steel coils used in the manufacturing of medical equipment?

- Steel coils are used in the manufacturing of medical equipment as they provide strength, durability, and flexibility for various components. These coils are often used in the production of surgical instruments, medical devices, and diagnostic equipment where precision and reliability are crucial.

- Q: What are the common methods of inspecting steel coils for defects?

- The common methods of inspecting steel coils for defects include visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing.

- Q: the difference between the original steel and mild steel from percentage of carbon

- As the first answers suggest, the prolbem is that these terms are not specific, they are not scientifically or technically defined. This is like asking: what is the difference between a four door car and a sedan? There are hundreds of steel alloys ranging from Fe + a little C + very little else to alloy and tool steels with significant amounts of Cr, Ni, Si, and a number of other elements + C. And... for any given steel alloy, there are many different ways to heat treat it. A given piece of steel can be heat treated so hard and brittle that it could shatter like glass and then it could be heat treated to make it into a spring or heat treated to make it stretch like taffy. If you really want to understand steels, yes, there are lots of books on sword making (some written by people who actually understand steels) but... you need to study metallurgy. There are graduate level courses just on the metallurgy of steels. Of course to understand this course you need to understand a whole lot of fundamental metallurgy. All this stuff on steel makes perfect sense because, in terms of weight (tonage) produced, steel is, hands down, nothing else remotely comes close, the most important metal humans have.

- Q: What are the different types of steel coil surface treatments for outdoor applications?

- There are several types of steel coil surface treatments suitable for outdoor applications. These include galvanization, which involves coating the steel with a layer of zinc to protect against corrosion; zinc-aluminum alloy coating, which provides enhanced corrosion resistance; paint coating, which adds a layer of protective paint to the steel surface; and organic coating, which uses a polymer-based material to protect against weathering and corrosion.

- Q: How are steel coils inspected for straightness using laser alignment?

- The straightness of steel coils is examined using laser alignment technology in a precise and automated manner. This technology offers a non-contact approach to measuring the straightness of steel coils with high accuracy and efficiency. To begin with, a conveyor system is utilized to move the steel coil through the inspection area. As the coil passes through, a laser alignment system is set up to emit a laser beam across the width of the coil. This laser beam acts as a reference line for measuring straightness. The laser alignment system consists of a laser emitter and a receiver unit. The emitter projects a perfectly straight and parallel laser beam for alignment purposes. On the opposite side of the coil, the receiver unit captures the laser beam and analyzes its position. As the coil progresses through the inspection area, the receiver unit determines the deviation of the laser beam from the desired straight line. This is accomplished by analyzing the position of the laser beam at multiple points along the width of the coil. The laser alignment system is connected to a computerized control system that processes the data obtained from the receiver unit. The control system performs intricate calculations to determine the straightness of the coil based on the position of the laser beam. Any variations or deviations from the desired straight line are recorded and thoroughly examined by the control system. The inspection data can be viewed in real-time, enabling operators to monitor the straightness of the steel coil during the inspection process. The use of laser alignment technology for steel coil inspection offers numerous benefits. It provides highly precise measurements, ensuring that even slight deviations from straightness are detected. Furthermore, the non-contact nature of laser alignment eliminates the need for physical contact with the coil, thus reducing the risk of damage or contamination. Additionally, the automated process saves time and enhances efficiency compared to manual inspection methods. In conclusion, laser alignment technology is a dependable and efficient method for inspecting the straightness of steel coils. It guarantees that only coils meeting the required straightness criteria are approved, thereby contributing to the quality control of steel manufacturing processes.

- Q: What are the different types of steel coil surface finish treatments?

- There are several different types of steel coil surface finish treatments, including hot-dip galvanizing, electro-galvanizing, zinc plating, powder coating, and painting. These treatments are applied to steel coils to enhance their durability, corrosion resistance, and aesthetic appeal.

Send your message to us

Hot-Dip Aluzinc Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords