Honeycomb Aluminum Sheets Weight - Color Coated Aluminum Embossed Coil Foil Roll for Food 2024 China Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

(4),Color coating steel is cold rolled steel sheet and galvanized steel substrate, after surface pretreatment (degreasing, cleaning, chemical conversion treatment), with the method of continuous coated with paint (roller coating method), after baking and cooling and manufactured products.

3. Feature of Aluminum

1100-H14-DIAMOND EMBOSSED ALUMINUM SHEET

Thickness:1.2mm---4mm,

width:1000mm---1500mm

Product code: 618 a - 33 y titanium matte aluminum plate

Technical parameters

Aluminum alloy/material: 1100

Tensile strength N/was: 115-125

The yield strength of N/was: 150-150

Elongation % : 3 or more

Rainbow degrees: no

Process: light oxidation process

Product description: surface "colored metal silken face" as the main characteristics of the product, completely metal texture, color variety, products can be mild tensile and bending.

Product use: can be used to directly shape stamping, screen printing, thermal transfer two composite process, etc.Used in architectural decoration, household appliances, switch panel, auto parts, lamps lighting, electronic hardware and other industries.

Supply scope of coil or sheet

Mm thickness specification: 0.4 1

Maximum width mm: 1250

The tolerance range

Mm thickness: 0.02 mm

The width of the mm: 2 -

Mm length: 2 -

Actual weight kg: plus or minus 2

Protective film

Protective film on the surface of the aluminum quality assurance period for six months, aluminum is kept dry and ventilated, avoid heat and direct sunlight.If the aluminium material stored in high temperature or direct sunlight can cause protective film, or unable to tear in addition to wait for a phenomenon.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

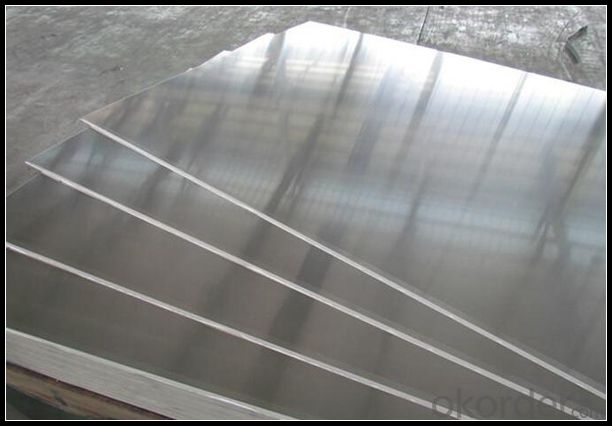

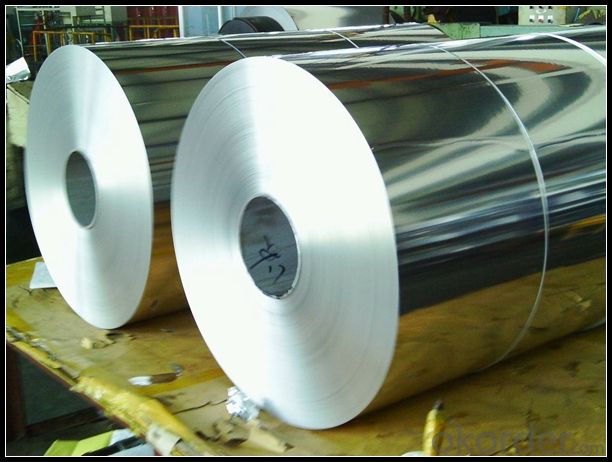

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Can aluminum sheets be used for bus shelters?

- Yes, aluminum sheets can be used for bus shelters. Aluminum is a lightweight and durable material that is commonly used in construction projects, including bus shelters. It offers excellent resistance to corrosion, making it suitable for outdoor applications where it may be exposed to harsh weather conditions. Additionally, aluminum sheets can be easily formed and fabricated into various shapes and sizes, allowing for customized designs and easy installation. The use of aluminum sheets for bus shelters also provides a cost-effective solution as it requires minimal maintenance and has a long lifespan.

- Q: What is the difference between aluminum plate and aluminum-plastic plate?

- Simply put, aluminum plate is pure metal, aluminum plate is only the surface of metal (surface metal processing), and the middle is polyethylene plastic.In the same thickness and specifications, the aluminum plate is heavier than the aluminum-plastic plate, and the price is generally higher than that of the aluminum plate. 2.5mm aluminum plate to see, polyester or fluorocarbon, aluminum material, machining drawings, are often n flat at around 250, aluminum plate, aluminum depends on the thickness of the plastic type and so on normal inner wall 40 yuan a square, 100 yuan per square wall aluminum plate and aluminum plate installation is a kind of the aluminum is only good processing and molding to the site, and then to the site after the aluminum plate molding, aluminum plate manufacturer's website will generally some. There are also some details please consult the steel E station through

- Q: Hey I just noticed that my deodorant/antiperspirant has aluminum in it. I remember reading that this is bad for you. My question is, will this be dangerous for my health in the long run?

- Deodorants do not contain aluminum, only antiperspirants do. The aluminum is used to stop sweating from occurring. There are natural antiperspirants (example Tom's of Main) that claim to stop sweat without the use of aluminum. Aluminum based products have been associated with quite a few health problems: Seizures Breast Cancer Alzheimer's Disease Bone Formation Disorders Kidney Problems Hope this helps.

- Q: Are aluminum sheets suitable for electrical transformers?

- Yes, aluminum sheets are suitable for electrical transformers. Aluminum has excellent electrical conductivity, lightweight properties, and good thermal conductivity, making it an ideal choice for transformer applications. Additionally, aluminum is cost-effective and readily available, further contributing to its suitability for use in electrical transformers.

- Q: Are aluminum sheets resistant to impact?

- Aluminum sheets, in general, have a resistance to impact. With its lightweight nature, aluminum is a metal that possesses both strength and toughness, enabling it to endure impact forces. It boasts remarkable energy absorption qualities, facilitating the absorption and dispersion of impact-generated energy, thereby reducing harm to the sheet. Moreover, aluminum sheets can be fortified further through techniques like heat treatment or alloying, enhancing their impact resistance. Nonetheless, the impact resistance of aluminum sheets may fluctuate based on the particular alloy and thickness employed.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- If you are using tinfoil it is because it is coated with aluminum oxide which has a melting point of 2,000 degrees celcius.

- Q: What is the typical density of aluminum sheets?

- The typical density of aluminum sheets is approximately 2.7 grams per cubic centimeter (g/cm³). Aluminum is a lightweight metal with a relatively low density compared to other commonly used metals such as steel. This low density makes aluminum sheets suitable for various applications where a lightweight material is desired, such as in the aerospace industry, automotive manufacturing, and construction.

- Q: How do aluminum sheets perform in terms of fatigue resistance?

- Aluminum sheets are known for their excellent fatigue resistance. This means they are capable of withstanding repeated cycles of stress and strain without experiencing significant deterioration in their mechanical properties. Fatigue resistance in aluminum sheets is primarily attributed to their microstructure, which consists of small and uniformly distributed grains. This microstructure helps in distributing the applied stress more evenly throughout the material, preventing the formation and propagation of cracks. Additionally, aluminum sheets can be further enhanced for fatigue resistance through various processing techniques such as heat treatment, alloying, and surface treatments. These techniques can refine the microstructure, increase the strength, and improve the overall fatigue performance of the material. Moreover, aluminum has a relatively low density compared to other metals, which contributes to its superior fatigue resistance. The low density allows for better energy absorption during cyclic loading, reducing the likelihood of crack initiation and propagation. However, it is important to note that fatigue resistance can vary depending on the specific alloy, temper, and thickness of the aluminum sheet. Different aluminum alloys have different mechanical properties and fatigue limits, so it is crucial to select the appropriate alloy and temper based on the specific application requirements. Overall, aluminum sheets are well-regarded for their excellent fatigue resistance, making them a popular choice in industries requiring materials that can withstand cyclic loading and extended service life.

- Q: Can aluminum sheets be used for decorative wall panels?

- Aluminum sheets are indeed suitable for decorative wall panels. As a versatile material, aluminum offers a wide array of design options for wall panels. It is lightweight, durable, and resistant to corrosion, making it perfect for both indoor and outdoor applications. Aluminum sheets can be easily cut, formed, and fabricated into various shapes, patterns, and finishes, allowing for limitless design possibilities. Moreover, aluminum can be enhanced in appearance and provided with extra protection against wear and tear through powder-coating or anodizing. Whether it's for residential or commercial spaces, aluminum sheets can impart a modern and stylish touch to any wall, rendering them a highly sought-after choice for decorative wall panels.

- Q: There are about 200 holes on the aluminum plate to be machined. There are 100 M12 thread holes, and the rest are 15MM through holes. The tolerance is +0.02. Seeking detailed processing technology, is the first hole or first processing plane, how to control the amount of deformation of the plate, if the milling process can not guarantee flatness, on the grinder, then the 2 surfaces to stay 2MM margin? Are there any 15MM through holes that can be used to maintain tolerances, or do they need to be boring?. Great God advice, the best detail. Aluminum so much done before, no experience, if it does it scrapped.

- Brother, I want to tell you first, the aluminum grinding machine is very rare! Because the aluminum sticky grinding wheel!No money, people are: 1., flying base level, thickness to 26.5 low point! 2. turn the face, press 4 sides, drill rough. The 3. lock bolt is in the hole you hit! Notice here that the lock must be locked one by one! Do you think the workpiece completely tied to lock dead in the fixture, and then processing the thickness to 25.6, the Kong Xian crude drilling reamer locking bolt end processing in place, lock 4. replacement bolts, the original lock bolt hole processing in place! 5., the final flying surface, according to each side of the 0.3 to fly surface, flying surface fixed method, you can use hot melt adhesive or hard rubber mud to fix the workpiece 4 sides and forming the inner hole!The rich person is the vacuum sucker, the base level as much as 26.5, turn over the surface of the vacuum sucker, forming directly!Hope to adopt, typing hard enough!

Send your message to us

Honeycomb Aluminum Sheets Weight - Color Coated Aluminum Embossed Coil Foil Roll for Food 2024 China Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords