Higher Finishing Surface CRC Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

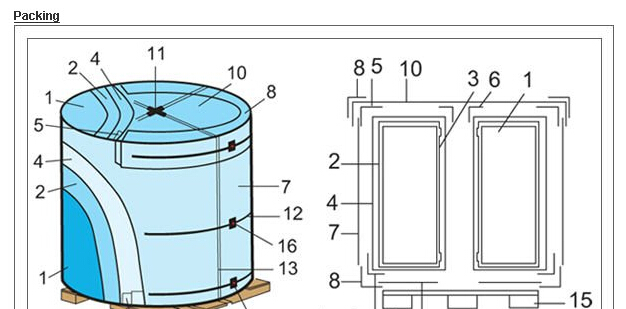

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508&610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

DC01 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

DC03 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

DC04 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness <0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: What are the different types of steel sheets and their uses in the packaging industry?

- There are various types of steel sheets used in the packaging industry, including tinplate, galvanized steel, and stainless steel. Tinplate is commonly used for food packaging due to its corrosion resistance and ability to maintain product freshness. Galvanized steel sheets are used for heavy-duty packaging, such as shipping containers, as they provide strength and durability. Stainless steel sheets are often used in the pharmaceutical industry for packaging sensitive or corrosive substances, thanks to their resistance to chemical reactions and contamination.

- Q: How does steel pipe threading work?

- Steel pipe threading is a process where a steel pipe is cut with a specialized tool to create external threads, which allows for the connection of fittings and other pipes. The threading tool, typically a die, is applied to the pipe, and as it is rotated, it gradually cuts grooves into the pipe's surface, forming the threads. This threading process ensures a secure and leak-free connection when joining pipes together.

- Q: How do steel products contribute to the infrastructure development of cities and urban areas?

- Steel products play a crucial role in the infrastructure development of cities and urban areas. Due to their high strength, durability, and versatility, steel products are widely used in the construction of buildings, bridges, roads, and other essential structures. Steel's ability to withstand heavy loads and extreme weather conditions makes it an ideal choice for constructing tall buildings and long-span bridges, ensuring the safety and longevity of these structures. Additionally, steel's recyclability and sustainability make it an environmentally-friendly choice, contributing to the sustainable development of cities and urban areas. Overall, steel products are essential in creating robust and resilient infrastructure that supports the growth and development of cities and urban areas.

- Q: What are the different types of steel wire and cables available?

- There are several types of steel wire and cables available, including galvanized steel wire, stainless steel wire, carbon steel wire, and alloy steel wire. Each type has its own unique properties and characteristics, making them suitable for various applications such as construction, automotive, electrical, and telecommunications.

- Q: What are the different types of steel coils and their uses?

- There are several different types of steel coils that serve various purposes in different industries. Some common types include hot-rolled coils, cold-rolled coils, galvanized coils, and stainless steel coils. Hot-rolled coils are used in construction, automotive, and manufacturing industries for applications such as structural components and machinery parts. Cold-rolled coils are known for their precision and smooth surface finish, making them suitable for industries like appliances, automotive, and electrical equipment. Galvanized coils are coated with a layer of zinc, providing corrosion resistance, and are commonly used in construction, roofing, and outdoor applications. Stainless steel coils, which are highly resistant to corrosion and heat, find extensive use in kitchen appliances, automotive parts, and medical equipment.

- Q: How are steel forgings used in the aerospace industry?

- Steel forgings are used in the aerospace industry for various critical components such as landing gear, engine parts, turbine discs, and structural components. These forgings offer superior strength, durability, and resistance to high temperatures, making them ideal for withstanding the extreme operating conditions of aircraft. With precise shaping and rigorous quality control, steel forgings ensure the safety and reliability of aerospace systems.

- Q: How is steel used in the production of musical instruments?

- Steel is commonly used in the production of musical instruments due to its strength and versatility. It is often used in the construction of guitar strings, drum cymbals, and certain parts of brass and woodwind instruments. Steel provides a bright and vibrant sound, making it a popular choice in the manufacturing process.

- Q: How is steel used in the production of storage tanks and containers?

- Steel is commonly used in the production of storage tanks and containers due to its strength, durability, and resistance to corrosion. It is used to construct the shells and structural components of the tanks, providing a reliable and long-lasting solution for storing various liquids and gases. Additionally, steel can be easily fabricated and welded, allowing for customization and efficient manufacturing processes.

- Q: What are the challenges faced in the welding of steel products?

- Some challenges faced in the welding of steel products include ensuring proper joint preparation, maintaining the correct temperature and heat input, managing distortion and warping, preventing weld defects such as porosity or cracking, and ensuring proper shielding gas coverage. Additionally, factors such as the type and thickness of the steel, the welding technique used, and the skills and experience of the welder can also impact the challenges faced in the welding process.

- Q: How do steel products contribute to the construction of data centers and IT facilities?

- Steel products play a significant role in the construction of data centers and IT facilities by providing structural support, durability, and safety. Steel is widely used in the construction of the building's framework, ensuring the facility can withstand the weight of heavy equipment and support the complex infrastructure required for data storage and processing. The use of steel also allows for flexible and scalable designs, accommodating future expansions or modifications. Additionally, steel's fire-resistant properties help protect critical IT equipment from potential hazards, making it an essential component in ensuring the reliability and security of data centers and IT facilities.

Send your message to us

Higher Finishing Surface CRC Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords