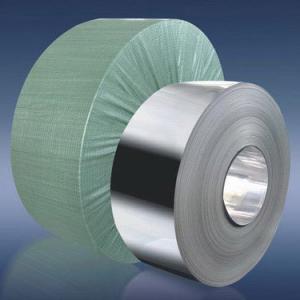

Higher Finishing Surface CRC Coil 0.4-2.0mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Thickness: 0.4-2.0mm

2. Width: 900-1250mm

3. Inner Diameter: 508 & 610mm

4. Weight of Steel Coil: 3-15MT

5. Heat Treatment: Annealed + Smoothed

6. Margin Status: EC & EM

7. Surface Quality: FC & FD

8. Surface Treatment: Oiling

9. Surface Status: Bright

Chemical Components

Grade | Chemical Components | ||||

C | Mn | P | S | Alt | |

St12 | ≤0.10 | ≤0.50 | ≤0.035 | ≤0.025 | ≥0.020 |

St13 | ≤0.08 | ≤0.45 | ≤0.030 | ≤0.025 | ≥0.020 |

St14 | ≤0.08 | ≤0.40 | ≤0.025 | ≤0.020 | ≥0.020 |

Mechanical Properties

1. Yield Strength: ≤320MPa

2. Tensile Strength: ≤370MPa

3. Elongation (L=50mm, b=25mm) When:

(1) Nominal Thickness<0.25mm: 30%

(2) Nominal Thickness 0.25mm-<0.40: 32%

(3) Nominal Thickness 0.40-<0.60mm: 34%

(4) Nominal Thickness 0.60-<1.0mm: 36%

(5) Nominal Thickness 1.0-<1.6mm: 37%

(6) Nominal Thickness >1.6mm: 38%

- Q: How do steel products contribute to the construction of dams and reservoirs?

- Steel products play a vital role in the construction of dams and reservoirs due to their durability, strength, and versatility. Steel is used extensively in the structural components of dams, such as gates, spillways, and penstocks, as it can withstand high pressures and heavy loads. Additionally, steel reinforcement bars are incorporated into the concrete to enhance its tensile strength, ensuring the structure's stability. Steel sheets and plates are also employed for lining tunnels and creating watertight barriers. Overall, steel products provide the necessary strength and reliability required for the successful construction and long-term functionality of dams and reservoirs.

- Q: How does steel sheet metal fabrication work?

- Steel sheet metal fabrication involves the process of shaping and manipulating steel sheets into desired forms and structures using various techniques such as cutting, bending, and assembling. This is typically done through the use of specialized machinery and tools, such as laser cutters, press brakes, and welders. The steel sheets are first cut into the required shape, either manually or through automated processes. Then, they are bent or formed using press brakes to achieve the desired angles or curves. Finally, the individual parts are assembled together through welding, fastening, or other joining methods, resulting in a finished steel sheet metal product.

- Q: What are the different methods of testing the quality of steel products?

- There are several methods of testing the quality of steel products, including destructive and non-destructive testing methods. Destructive testing involves subjecting the steel to extreme conditions, such as tension, compression, or bending, to determine its mechanical properties and strength. Non-destructive testing methods include visual inspection, ultrasonic testing, magnetic particle testing, and radiographic testing, which allow for the detection of defects or irregularities in the steel without causing any damage. These testing methods help ensure that steel products meet the required quality standards and are fit for their intended applications.

- Q: What are the advantages of using steel wire ropes?

- There are several advantages of using steel wire ropes. Firstly, steel wire ropes have high strength and durability, making them suitable for heavy lifting and pulling tasks. They can handle high loads and provide excellent resistance to wear and tear. Secondly, steel wire ropes have excellent flexibility, allowing them to be used in various applications and easily maneuvered around corners and obstacles. Thirdly, steel wire ropes have a long lifespan, requiring less frequent replacements compared to other materials. Lastly, steel wire ropes have high resistance to corrosion, making them suitable for outdoor and marine environments.

- Q: What are the common types of steel products used in the pet food and supplies industry?

- Some common types of steel products used in the pet food and supplies industry include stainless steel bowls, food storage containers, and grooming tools such as scissors or brushes.

- Q: How is steel used in the manufacturing of textile materials?

- Steel is not typically used in the manufacturing of textile materials. Instead, textiles are usually made from natural fibers like cotton or synthetic fibers like polyester. Steel, on the other hand, is commonly used in the construction of textile machinery or equipment, such as looms or knitting needles.

- Q: How is steel plate produced?

- Steel plates are produced through a process called steelmaking, where iron ore is melted in a blast furnace along with other elements like limestone and coke. This molten iron is then refined and converted into steel by removing impurities through various methods such as oxygen blowing or electric arc furnaces. The steel is then cast into slabs or billets, which are further rolled into desired thicknesses and shapes to produce steel plates.

- Q: How does steel pipe welding work?

- Steel pipe welding works by using heat to melt the edges of two steel pipes together, creating a strong and continuous joint. The process involves applying a high-temperature heat source, such as an electric arc or flame, to the pipes' ends, causing them to reach their melting point. As the edges melt, a filler material, often in the form of a welding rod or wire, is added to the joint to reinforce and fuse the pipes together. This molten filler material solidifies upon cooling, forming a durable and reliable bond between the pipes.

- Q: How does steel compare to other materials like aluminum or wood?

- Steel is generally stronger and more durable than both aluminum and wood. It has a higher tensile strength, making it better suited for structural applications. Steel is also more resistant to fire, pests, and rotting compared to wood. On the other hand, aluminum is lighter and more corrosion-resistant than steel, making it preferable for certain applications like aerospace or marine industries. Ultimately, the choice between steel, aluminum, or wood depends on the specific requirements and characteristics needed for a particular project.

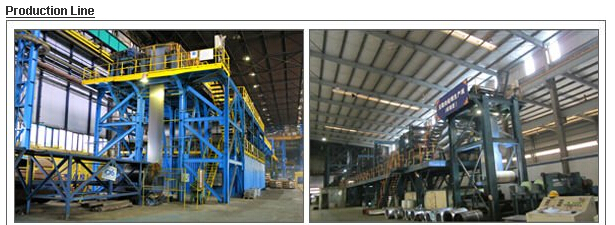

- Q: How is steel coil produced?

- Steel coil is produced through a process called hot rolling, where a slab of steel is heated and passed through a series of rolling mills to reduce its thickness and increase its length. The steel is first cleaned and descaled, then heated to an extremely high temperature. It is then passed through a series of rolling mills that gradually decrease the thickness of the steel, while increasing its length. Finally, the steel is cooled and coiled into large rolls, known as steel coils, ready for further processing or shipment.

Send your message to us

Higher Finishing Surface CRC Coil 0.4-2.0mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords