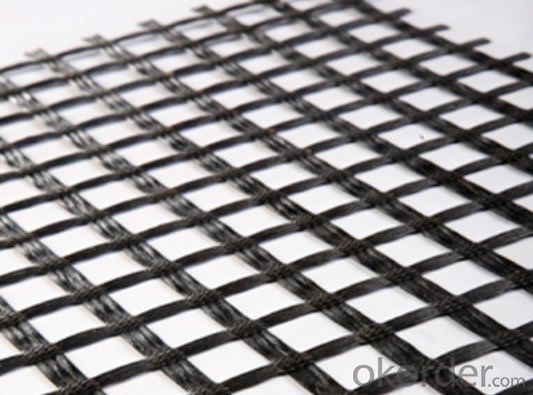

High Tensile Strength Fiberglass Geogrid Geotextile Soil Fabric for Civil Engineering

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

Type:

Geogrids

Place of Origin:

Jiangsu, China (Mainland)

Brand Name:

Lonrace

Model Number:

geogrid

Material:

Polyester

Color:

White Black Gray Etc

Tensile strength:

25Kn/m--300Kn/m

Length:

50-100m

Certification:

CE /ISO9001

Coating:

PVC

Geogrids are an economical solution for filling water stream base and creates almost an ideal surface for laying down a water resistant layer.

Slopes and subgrades with rails are a serious problem in railroad construction. Under high pressure the layers slide and deform consequently causing rail deformation, which requires closing railroad segments for a long time. Geogrid application allows carrying out comlex repair operations of the necessary road segment in shortest time (which is very essential in transportation).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geotextiles contribute to climate change adaptation?

- Geotextiles contribute to climate change adaptation by providing effective solutions for erosion control, slope stabilization, and flood prevention. By reinforcing soil and preventing erosion, geotextiles help to protect vulnerable areas from the impacts of climate change, such as increased rainfall and extreme weather events. They also aid in water management by reducing sediment runoff and improving overall drainage systems. Additionally, geotextiles can be used in the construction of green infrastructure, such as permeable pavements and green roofs, which help mitigate urban heat island effects and improve stormwater management. Overall, geotextiles play a crucial role in enhancing resilience to climate change impacts and promoting sustainable development.

- Q: Characteristics of nonwoven geotextiles

- Non-woven geotextile has many advantages: 1) air permeability 2) filterability 3) insulation 4) water absorption 5) waterproof 6) stretch 7) not disheveled 8) feel good, soft 9) light 10) Can be restored 11) without the direction of the fabric 12) compared with the textile production of high productivity, production speed 13) low prices, can be mass production and so on. Disadvantages are: 1) Compared with the textile fabric strength and durability is poor; 2) can not be washed as other fabrics; 3) fiber arranged in a certain direction, so easy to split from the right angle and so on. Therefore, the improvement of the production method has been mainly focused on preventing the improvement of the division.

- Q: What are the different installation guidelines for geotextiles in reinforcement projects?

- The installation guidelines for geotextiles in reinforcement projects typically involve the following steps: 1. Site Preparation: Clear the construction area of any vegetation, debris, or loose soil. Level the ground and remove any protrusions or sharp objects that could damage the geotextile. 2. Geotextile Placement: Unroll the geotextile over the prepared area, ensuring it covers the entire project site. Overlaps between adjacent rolls should be at least 1 to 2 feet to provide proper continuity. 3. Anchoring: Secure the geotextile at the edges using anchor trenches, stakes, or other appropriate methods to prevent movement during installation or in the long term. 4. Jointing: Overlap adjacent geotextile panels by a minimum of 1 to 2 feet, depending on the project requirements. Secure the overlap with appropriate fasteners or adhesives to ensure proper functioning. 5. Protection: If necessary, cover the geotextile with a protective layer, such as a layer of soil or aggregate, to shield it from potential damage during construction activities or exposure to UV radiation. 6. Compaction: If the project involves soil stabilization or reinforcement, follow the recommended compaction procedures to ensure proper integration of the geotextile with the surrounding soil or aggregate. 7. Quality Control: Regularly inspect the geotextile installation to ensure that it is properly placed, free of damage, and functioning as intended. Any identified issues should be addressed promptly. It is important to note that specific installation guidelines may vary depending on the project type, site conditions, and the type of geotextile being used. It is recommended to consult the manufacturer's recommendations and seek professional guidance to ensure proper installation.

- Q: Where is the geotextile in the municipal works?

- Conservation, consideration, there is more green and more Chinese geotextile material manufacturers

- Q: What glue glue is used at the seams of the impervious geotextile

- What glue glue is used at the seams of the impervious geotextile

- Q: What are the specifications for geotextiles in civil engineering projects?

- Geotextiles used in civil engineering projects have specific specifications related to their strength, permeability, durability, and filtration properties. These specifications ensure that geotextiles can effectively separate, reinforce, filter, and drain soil or other materials in various construction applications such as roads, embankments, slopes, and retaining walls.

- Q: Are geotextiles resistant to creep deformation?

- Yes, geotextiles are generally resistant to creep deformation. Geotextiles are designed to have high tensile strength and low creep properties, allowing them to withstand long-term loads and maintain their original shape and dimensions over time.

- Q: How do geotextiles help in the separation of materials?

- Geotextiles help in the separation of materials by acting as a barrier between different layers of soil or other materials. They prevent the mixing or migration of particles, such as preventing fine soil from mixing with coarse aggregate in road construction, ensuring proper drainage and stability.

- Q: Geotextile cloth and no square what meaning

- Geotextile, also known as geotextile, originated in the twentieth century, the fifties. Raw materials are polyester, polypropylene, acrylic, nylon and other polymer polymer synthetic fiber. Geotextiles are woven and non-woven. Not "Square", it is divided by the manufacturing process, the use of textile technology made of geotextile called spinning, and vice versa for non-woven geotextile. Due to the low cost of spinning geotextile, the cost is slightly higher. Most of the current engineering applications are non-woven geotextiles. They have a filter, filter, isolation, reinforcement, protection, and other functions.

- Q: What are the different weight options available for geotextiles?

- Geotextiles typically come in a range of weight options, which can vary from lightweight to heavyweight. These weight options are measured in terms of grams per square meter (gsm) or ounces per square yard (oz/yd²). The specific weight option chosen for a geotextile depends on the project requirements, such as the soil conditions, desired strength, and intended application.

Send your message to us

High Tensile Strength Fiberglass Geogrid Geotextile Soil Fabric for Civil Engineering

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords