High Temperature Resistance Silica Chopped Fiberglass Fabric Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Image:

Product Description & Application:

It is high temperature resistant product.Mixed a ratio of organic fiber in the chopped silica fiberglass and put into fiberglass or stainless steel wire as reinforcement to spun the yarn,and then woven into the cloth.(stainless steel wire or fiberglass reinforced)

Application:

As the external insulation layer for industrial furnaces and other external heat preservation and heat insulation for a variety of mechanical equipment and pipeline;

As welding spark cloth for building,ship,large construction equipment industry;

Fireproof and heat indulation for rail vehicle,vehicle transportation insulation parts;

Can be processed into the fire-proof curtain in the building ,fireproof garment( covered aluminum),fireproof gloves,fireproof shoes,etc.

Product Capability:

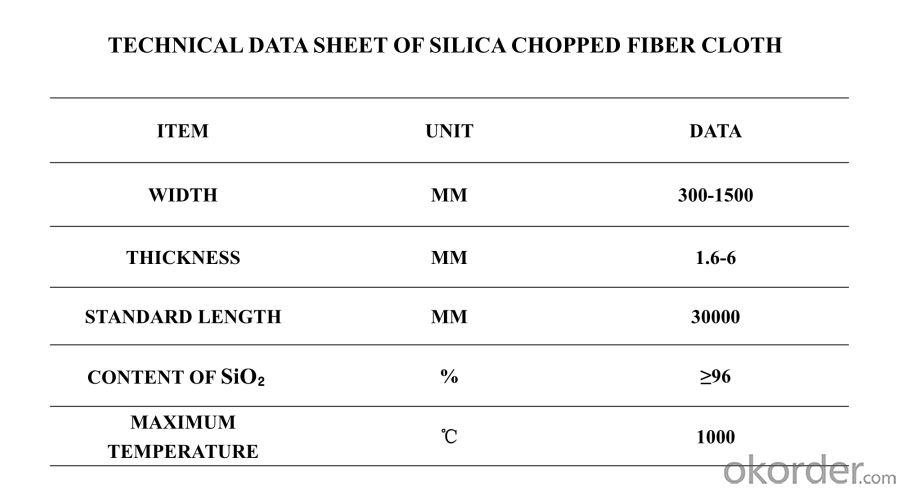

SiO2>=96%;

Compared with the traditional high silica fiberglass cloth,the advantage of this cloth is that can be reinforced with stainless steel wire,have strong resistance performance,can be folded,thick and light weight,high air tightness;

The skin irritation is very small,no dust,can replace the traditional ceramic fiber cloth;

Higher temperature resistant,insulation,low heat conduction rate;

High thermal and chemical stability,good dielectric properties.

Data Sheet:

Silica fiber products:

A kind of inorganic high temperature resistance fiber with the content of SiO₂ higher than 95%, its soften temperature can nearly reach to 1700℃.It can be used in high temperature environment below 900℃ for a long time.

- Q: Is fiberglass fabric suitable for making backpacks and bags?

- While fiberglass fabric can indeed be used for creating backpacks and bags, it does not rank as the most prevalent or favored material. Renowned for its robustness, endurance, and fire resistance, fiberglass fabric proves to be an excellent option for applications that necessitate these qualities. Nevertheless, it may lack the flexibility and lightweight nature commonly found in backpacks and bags fashioned from polyester or nylon, materials more frequently utilized for this purpose. Moreover, fiberglass fabric tends to be pricier and less skin-friendly. In addition, precautionary measures must be taken during manufacturing to prevent the release of loose fibers, which can cause skin and respiratory irritations. Therefore, while fiberglass fabric can be deemed suitable for certain scenarios, it may not be the most practical or comfortable choice for everyday use or individuals with specific needs or sensitivities.

- Q: What is the heat resistance of fiberglass fabric?

- The heat resistance of fiberglass fabric is quite high. It can withstand temperatures up to 1000 degrees Fahrenheit (537 degrees Celsius) without any significant damage or degradation. This makes it an excellent choice for applications that involve exposure to intense heat, such as welding blankets, insulation materials, and fire-resistant clothing. Additionally, fiberglass fabric has a low thermal conductivity, meaning it does not conduct heat well, providing an added layer of protection in high-temperature environments.

- Q: Can fiberglass fabric be used for welding blankets?

- Indeed, welding blankets can make use of fiberglass fabric. Possessing heat-resistant qualities and remarkable fire-retardant features, fiberglass fabric proves itself as an ideal choice for safeguarding against sparks, slag, and molten metal during welding procedures. Its ability to endure high temperatures without succumbing to melting or burning establishes it as a dependable shield between the welding area and nearby objects. Moreover, fiberglass fabric's lightweight and pliable nature make it effortless to handle and maneuver. Its durability and resilience against abrasion additionally enhance its aptness for welding blankets, guaranteeing enduring protection and safety within welding environments.

- Q: Is fiberglass fabric suitable for use in protective masks?

- Yes, fiberglass fabric is suitable for use in protective masks. It is known for its high strength, durability, and resistance to heat, chemicals, and abrasion. Additionally, fiberglass fabric can provide excellent filtration properties, making it an effective barrier against airborne particles and contaminants. However, it is important to note that proper precautions should be taken during the manufacturing process to prevent the release of loose fibers, which can be harmful when inhaled.

- Q: The influence of bag dust removal on dust filtration

- In flannel cloth through teaseler pull scrape with fluff fabric. When the dust is filtered, the dust particles are first captured by a porous layer of fluff, and most of them are supported by a force of latitude and latitude. Subsequently, a dense and dense porous dust layer is formed on the undercoat layer. Due to the large amount of dust cloth Bisubu, so Bisubu high efficiency dust filter. Which is porous media by single fiber, disorderly deposits thicker, has the characteristics of internal filter in a certain extent. Not only the felt itself has a certain ability to filter dust, but also a large amount of dust, so even if the surface does not form a dust layer, but also to ensure a higher dust filter efficiency.

- Q: What are the different finishes available for fiberglass fabric rolls?

- Some of the different finishes available for fiberglass fabric rolls include plain weave, leno weave, satin weave, twill weave, and herringbone weave. These finishes determine the pattern and texture of the fabric and can impact its strength, flexibility, and durability. Additionally, there are finishes that can be applied to fiberglass fabric rolls to enhance properties such as fire resistance, water repellency, and chemical resistance.

- Q: Can fiberglass fabric be used for making insulation blankets?

- Indeed, insulation blankets can be manufactured using fiberglass fabric. Renowned for its remarkable thermal insulation qualities, fiberglass fabric proves to be a perfect material for crafting insulation blankets. These blankets are specifically engineered to confine heat and hinder its transmission, ensuring efficient insulation across diverse contexts like residential abodes, industrial environments, as well as aerospace and automotive sectors. Typically, the fiberglass fabric employed in insulation blankets is woven or knitted, rendering it supple and effortlessly modifiable to suit various shapes and dimensions. Moreover, fiberglass fabric exhibits traits of being lightweight, fireproof, and resistant to both chemicals and moisture, thereby establishing itself as a dependable option for insulation purposes.

- Q: How do fiberglass fabrics perform in terms of UV resistance?

- Fiberglass fabrics generally have excellent UV resistance due to the inherent properties of the material. The fibers used in fiberglass fabrics are typically made of glass, which is naturally resistant to UV rays. This resistance allows fiberglass fabrics to withstand prolonged exposure to sunlight without significant degradation or weakening. As a result, these fabrics are often used in outdoor applications where UV protection is crucial, such as in awnings, sunshades, or boat covers.

- Q: What are the maintenance requirements of fiberglass fabric?

- Compared to other materials, fiberglass fabric has relatively low maintenance requirements. However, there are a few factors to consider in order to ensure its longevity and optimal performance. To begin with, it is necessary to regularly clean the fabric to remove any accumulated dirt, dust, or debris. This can be achieved by gently vacuuming or using a soft brush to remove loose particles. It is important to avoid using harsh chemicals or abrasive cleaners, as they have the potential to damage the fabric. Alongside cleaning, it is crucial to periodically inspect the fabric for any signs of wear or damage. Look out for fraying, tears, or loose threads, and address them promptly to prevent further deterioration. If repairs are necessary, it is recommended to seek professional advice or follow the manufacturer's instructions for proper repair techniques. Additionally, protecting the fiberglass fabric from excessive sunlight exposure is advisable. Prolonged exposure to UV rays can lead to fading or discoloration. Using UV-resistant coatings or treatments can help mitigate this issue and extend the fabric's lifespan. Lastly, proper storage of fiberglass fabric when not in use is essential for maintaining its quality. It should be stored in a clean and dry environment, away from moisture or extreme temperatures. Rolling or folding the fabric neatly and avoiding any sharp objects or heavy items on top of it will help prevent creasing or damage during storage. By adhering to these maintenance requirements, fiberglass fabric can retain its durability, appearance, and functionality for an extended period of time, making it a reliable choice for various applications.

- Q: How does fiberglass fabric perform in high-vibration environments?

- Due to its unique properties, fiberglass fabric is highly effective in high-vibration environments. It possesses inherent stiffness and a high strength-to-weight ratio, making it resistant to vibrations and mechanical stress. When exposed to vibrations, fiberglass fabric efficiently absorbs and disperses the energy, minimizing potential damage and reducing impact. One of the main advantages of fiberglass fabric is its excellent ability to dampen vibrations. It can absorb and dampen vibrations, preventing them from spreading and intensifying throughout the structure. This characteristic is especially important in high-vibration environments, as excessive oscillations can lead to structural fatigue, decreased performance, or even failure. Furthermore, fiberglass fabric is known for its exceptional durability and resistance to corrosion, enhancing its performance in high-vibration environments. It can withstand prolonged exposure to intense vibrations without experiencing degradation or loss of mechanical properties. Additionally, fiberglass fabric offers versatility in design and application. It can be easily molded or woven into various shapes and sizes to meet specific requirements in high-vibration environments. Whether used as a reinforcement material in composites or as a standalone fabric, fiberglass provides reliable and long-lasting performance in demanding conditions. In conclusion, fiberglass fabric is an ideal choice for high-vibration environments due to its stiffness, strength, damping properties, durability, and resistance to corrosion. Its ability to absorb and dissipate vibrations, combined with its design versatility, makes it well-suited for applications where mitigating vibration-related issues is crucial.

Send your message to us

High Temperature Resistance Silica Chopped Fiberglass Fabric Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords