High Temperature Ceramic Fiber Paper 1430℃ for Gaskets

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Fiber Paper

l Okorder ceramic fiber paper is manufactured with high purity refractory fiber. The advanced technology makes the distribution of fiber very even.

l Okorder ceramic fiber paper is made with minimum bond. The ceramic fiber paper will be completely burnt during the usage.

l Ceramic Fiber Paper has great flexibility, mechanical performance, and excellent refractory and high temperature insulating performance.

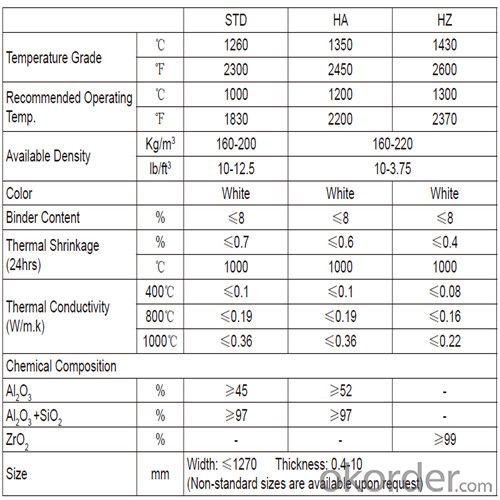

Specifications of Ceramic Fiber Paper

Width: ≤1270mm

Thickness: 0.4-10mm

(Non-standard sizes are available upon request)

Features of Ceramic Fiber Paper

Superior insulating properties

Contains no asbestos

Contains minimal bonding agent

Great white color, easy to cut, wrap or form a shape

Excellent temperature stability

Low thermal conductivity

Low heat storage

Image of Ceramic Fiber Paper

Technical Data of Ceramic Fiber Paper

Typical Applications of Ceramic Fiber Paper

High temperature gasket

Boiler door seal

Refractory expansion joint

Furnaces backup insulation

Lining for aluminum casting molds

Thermal and electrical insulation for heaters

Heat insulation for exhaust tubes and pipes

Acoustic and thermal insulation for automobile mufflers

Electrical switch box fire protection

Who We Are

l OKorder is offering high quality Ceramic Fiber Module at great prices with worldwide shipping. Our supplier is a world-class manufacturer of ceramic fiber products, with our products utilized the world over.

l OKorder annually supplies a full range of products to European, North American and Asian markets.

l We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisors.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Are ceramic fiber paper permeable?

- Ceramic fiber paper is said to be paper, in fact, is relatively large density, but still cotton like, it is permeableCeramic fiber composite board is able to play a certain waterproof effect

- Q: Is the slag ball of the ceramic fiber useful?

- According to the technical staff of Ji'nan Huolong thermal ceramics limited liability company, their company production of ceramic fiber paper and ceramic fiber board using slag ball dregs is removed, usually as raw materials into a new round of melting silk is melted again.

- Q: What's the fire resistance of the ceramic fiber?

- Because of the low heat conductivity, small density and light weight of the fiber, the light steel support structure is adopted in the design and construction of the kiln, which makes the development of the ceramic kiln into the lightweight era of the kiln. The fiber has small heat storage and is suitable for quick heating and cooling firing. Flexible fibers can be processed into products with grooves or openings, and has good resistance to mechanical shock and impact ability, chemical stability is good, these advantages for the development of new kiln, and spread to the development of ceramic industry, have an important role in promoting. The ceramic fiber products are: carpet, blanket, block, a variety of products like fiber, dispersion of fiber paper and vacuum forming, the work is generally in the range of 8711427 DEG C, under special circumstances can be short-term use in the high temperature limit temperature above the.

- Q: Can ceramic fibers be spun into fibers, please?

- TolerableToday's ceramic fiber fabrics are rope, cloth, tape, yarn, clothing, etc.

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- Ceramic fiber paper, with its superior product characteristics, has gained high status in the field of industrial high temperature insulation. It is generally used as insulation, heat preservation, sealing, electrical insulation, sound-absorbing and filtering materials. The utility model can be used not only as the inner wall of the lining, but also as the sealing material of the heat insulation material and the high temperature appliance, and can be used as the good heat insulation and cold protection material of the refrigeration equipment of the refrigerator.Ceramic fiber paper is widely used in various industrial furnace and ladle, ladle, submerged nozzle for high temperature heat insulation material; and industrial electric motor insulation and thermal insulation materials, sealing materials door and furnace expansion joints, in some high temperature instruments, equipment can also be used as insulation material; at the same time in the glass ceramics and heat melt glass film removing glass used as demoulding. Ceramic fiber paper has good sound insulation, noise reduction and noise reduction performance, so it can be used for silencer, insulation and insulation material of automobile exhaust pipe. Dragon Fire energy saving.

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- However, insulating bricks and refractory fibers can not be abused at will. So far as the basic oxygen furnace, cement rotary kiln lining, due to the high temperature chemical erosion, temporarily cannot be used for lining fiber. Ceramic fiber products (aluminum silicate fiber products) for continuous heating equipment such as ceramic tunnel kiln, has already achieved by ceramic fiber products (aluminum silicate fiber products) for continuous heating equipment lining, according to relevant reports, quickly push board kiln and tunnel kiln in the energy saving effect of fire resistant ceramic fibers are very significant. In particular, ultra high temperature heating, such as burning temperature in 1538 to 1649 degrees of furnace, the use of refractory fiber energy saving effect is best. Ceramic fiber products (aluminum silicate fiber products) at present, Europe and the United States and Japan all ceramic kiln equipment using ceramic fiber products (aluminum silicate fiber products) lining. Not long ago, Japan will be decomposed into compartments such as gas tunnel kiln structure, and then to the segmented manufacturing factory construction site assembly, all of this is due to the use of ceramic fiber material, greatly saves the cost of more convenient because of the kiln. The research on energy saving effect of ceramic fiber products is also being carried out from the aspects of material modification. Ceramic fiber products (aluminium silicate fiber products)

- Q: What are the prospects for ceramic fiber paper and how much investment will be needed?.

- It's a good prospect. I have friends around here who specialize in this. Not much investment.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper?

- Two ceramic fiber paper and ceramic fiber cloth are refractory insulation materials, both can be used for insulation and heat preservation

- Q: Carbon fiber and aluminum alloy material in the end what is the difference?

- The advantages of carbon fiber are light, excellent corrosion resistance, good elasticity and outstanding vibration absorption effect. The disadvantage is that the shock resistance is poor and the high temperature resistance is poor. It is used in a lot of planes, boats, sporting goods, such as bicycles, tennis rackets and so on. But the price is much more expensive than aluminum alloy.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Generally divided into standard type and high profile, the standard temperature of 1260 degrees to 1000 degrees of long-term use of high alumina long-term use of 1200 degrees.

Send your message to us

High Temperature Ceramic Fiber Paper 1430℃ for Gaskets

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 2000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords