Ceramic Fiber Paper - Thermal Shock Resilient Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Shock Resistant Ceramic Fiber Paper

Product Description:

Ceramic fiber paper is made from high quality clay, high purity alumina and silica oxides by spun or blown process. Ceramic fiber has a range of products: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products use different materials. The performance of ceramic fiber yarn is also different, and they are suitable for different working temperatures.

Ceramic fiber yarn can be used after optional cutting. When storing ceramic fiber, pay attention to moisture. The high-alumina type and containing zirconium type products can be directly used as furnace linings.

Product Features:

• Low thermal conductivity

• High tensile strength

• Resilient to thermal shock

• Corrosion resistance

Product Specifications:

Al Content (%): 32-55

Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

Density: 64-160kg/m³

Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

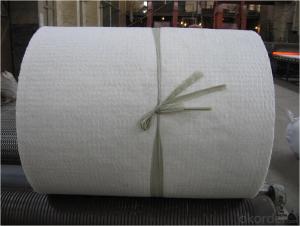

Product Packing:

Plastic bag in a carton box

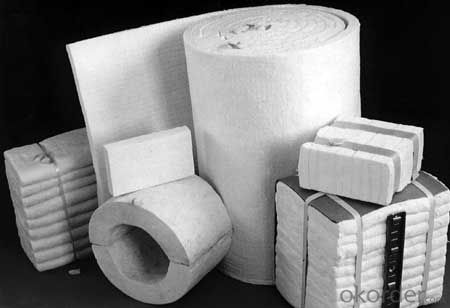

Product Images:

◆Packaging

◆Product Process

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- The insulation effect depends on the temperature. The same material, the temperature is different, thermal conductivity is not the same. At low temperatures, I suggest you use XPE. Ceramic fiber paper is generally used for hundreds of degrees or even thousands of degrees of high temperature.

- Q: What's the fire resistance of the ceramic fiber?

- Because of the low heat conductivity, small density and light weight of the fiber, the light steel support structure is adopted in the design and construction of the kiln, which makes the development of the ceramic kiln into the lightweight era of the kiln. The fiber has small heat storage and is suitable for quick heating and cooling firing. Flexible fibers can be processed into products with grooves or openings, and has good resistance to mechanical shock and impact ability, chemical stability is good, these advantages for the development of new kiln, and spread to the development of ceramic industry, have an important role in promoting. The ceramic fiber products are: carpet, blanket, block, a variety of products like fiber, dispersion of fiber paper and vacuum forming, the work is generally in the range of 8711427 DEG C, under special circumstances can be short-term use in the high temperature limit temperature above the.

- Q: Which insulation effect is better compared with ceramic fiber for STP insulation board?

- Solid energy saving STP insulation board, its insulation performance than traditional ceramic fiber insulation material is better than 3~4 times

- Q: Aluminum silicate blanket is used for heat preservation tube or aluminium silicate ceramic fiber paper

- The heat preservation of the pipe is usually made of aluminium silicate fiber blanket. The heat preservation of the base is made of aluminium silicate ceramic fiber paper. The insulation of the pipe is very little.

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- The manufacture of ceramic fiber paper was originally made of minerals! The production process is as follows: the ore is melted at high temperature, then the ceramic fiber is made by throwing the yarn, and finally, a lightweight insulating refractory material is made by wet forming process.

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- However, insulating bricks and refractory fibers can not be abused at will. So far as the basic oxygen furnace, cement rotary kiln lining, due to the high temperature chemical erosion, temporarily cannot be used for lining fiber. Ceramic fiber products (aluminum silicate fiber products) for continuous heating equipment such as ceramic tunnel kiln, has already achieved by ceramic fiber products (aluminum silicate fiber products) for continuous heating equipment lining, according to relevant reports, quickly push board kiln and tunnel kiln in the energy saving effect of fire resistant ceramic fibers are very significant. In particular, ultra high temperature heating, such as burning temperature in 1538 to 1649 degrees of furnace, the use of refractory fiber energy saving effect is best. Ceramic fiber products (aluminum silicate fiber products) at present, Europe and the United States and Japan all ceramic kiln equipment using ceramic fiber products (aluminum silicate fiber products) lining. Not long ago, Japan will be decomposed into compartments such as gas tunnel kiln structure, and then to the segmented manufacturing factory construction site assembly, all of this is due to the use of ceramic fiber material, greatly saves the cost of more convenient because of the kiln. The research on energy saving effect of ceramic fiber products is also being carried out from the aspects of material modification. Ceramic fiber products (aluminium silicate fiber products)

- Q: Do fiberglass or ceramic fiber paper have insulation effect?

- Glass fiber has low temperature resistance, preferably not higher than 550 degrees, and ceramic fiber has good temperature resistance.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper?

- Appearance。 The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.Density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.Thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.Stand upright。 Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. The ceramic fiber cloth is like the cloth used in our life. It is very soft and has no standing.Tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: What's the difference between ceramic fiber paper gasket and ceramic fiber gasket?

- Price: ceramic fiber gasket of the same size and thickness, ceramic fiber paper gasket is lower than ceramic fiber cloth gasket, although both are charged by weight, but the density difference is too big.

- Q: What fiber glass made of ceramic fiber paper?

- Ceramic fiber paper production process is:Beat out - pulp - pulp - long mesh forming - vacuum dehydration - drying - cutting - winding - packaging

Send your message to us

Ceramic Fiber Paper - Thermal Shock Resilient Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords