Ceramic Fiber Paper (1000C-1260C-1350C-1600C)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Fiber Paper (1000C-1260C-1350C-1600C)

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes .Ceramic fiber bulk shows a high temperature stability ,low weight and heat capacity and an outstanding sound absorption is complemented by their resistance to oxidation and reduction

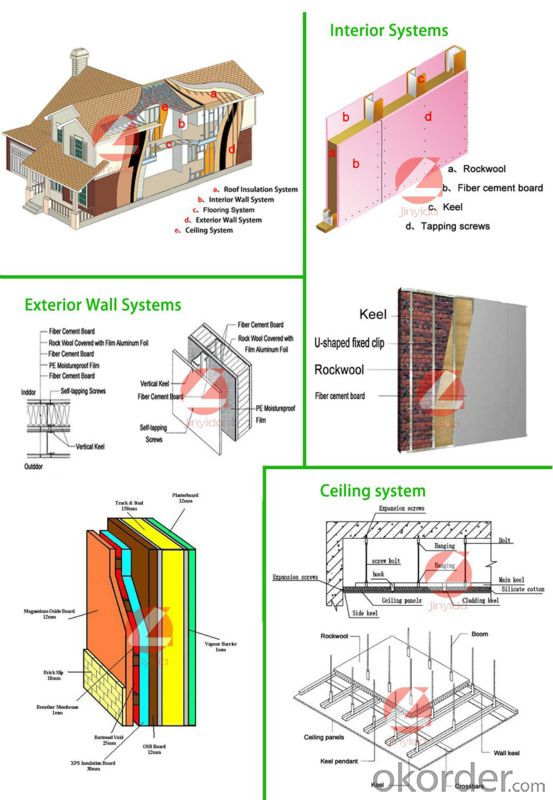

Product Applications:

Ceramic Fiber Bulk are ideal for use in the below applications

The industry kiln, heating device, high temperature pipe lining

Power boiler,gas turbine and heat and nuclear power insulation

Chemical industrial high temperature equipment and heating

equipment lining

Fireproof and heat insulation for high building

Heat insulation for Kiln door and roof.

High-grade household appliances thermal insulation device

High temperature filtration etc

Product Advantages:

CNBM has success in its ceramic fiber products due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in ceramic fiber blankets application and would like to assist you in product selection, system design, and installation techniques.

Main Product Features:

•Easy twisting, shaping and cutting

•Excellent machining performance

•Excellent tensile strength

•Acoustic performance

•Good anti-spalling properties

•Low thermal conductivity, low thermal capacity

•Resistance to wind and erosion, long service life

•Excellent thermal insulation, fire protection,

•Thermal insulation and acoustic performance

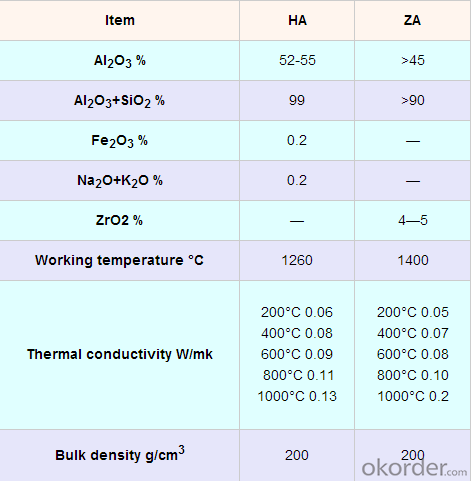

Product Specifications:

FAQ:

Q1.What is your MOQ?

A1 :MOQ may vary by customer's special requirement; we try our best to meet your business requirement.

Q2.Can you provide sample?

A2: Yes, we can offer sample , and some samples are free

Q3:Can you delivery by express?

A3: Yes, we can delivery by any express

Q4.Can you accept OEM ?

A4: YES! We can according your demand to produce.

Product Picture

Produce Processing

Product Picture

Produce Processing

- Q: Are ceramic fiber paper permeable?

- Ceramic fiber paper is said to be paper, in fact, is relatively large density, but still cotton like, it is permeableCeramic fiber composite board is able to play a certain waterproof effect

- Q: Is the slag ball of the ceramic fiber useful?

- There's not much use value, the only effect is recycled to reduce waste, prevent pollution two.

- Q: Is everybody ceramic fiber cotton poisonous?

- Depends on the production process is the above kind, the province may not, but the production process may have some problems.

- Q: Where is the best packing area for ceramic fibers?

- As the temperature continues to rise, the products will gradually become white, organic fiber has been completely carbonized products completely for the high temperature inorganic ceramic fiber resistant ceramic fiber (standard type) white maximum temperature ceramic fiber cloth content index color 1260 C fiber diameter 1-4 m thermal shrinkage (1232 C, 24h) 3.5% transmission rate (at 538 8pcf) three 0.130w/m.k two aluminum oxide content 45-48% 0.7-1.2% ferric oxide content of calcium oxide and sodium oxide content of 0.43% slag ball content <8.5% breakdown voltage 5 kv/mm resistance of 5 * 1010 ohm 3w.xxceramic content index white color thickness 1.5mm--6.0mm single 0.5 3kg/ square meters of organic fiber content <20% content <2% strengthening materials alkali glass fiber nichrome wire (1Cr18Ni9Ti)

- Q: What is the essential difference between the standard of ceramic fiber and ordinary aluminium silicate?

- However, insulating bricks and refractory fibers can not be abused at will. So far as the basic oxygen furnace, cement rotary kiln lining, due to the high temperature chemical erosion, temporarily cannot be used for lining fiber. Ceramic fiber products (aluminum silicate fiber products) for continuous heating equipment such as ceramic tunnel kiln, has already achieved by ceramic fiber products (aluminum silicate fiber products) for continuous heating equipment lining, according to relevant reports, quickly push board kiln and tunnel kiln in the energy saving effect of fire resistant ceramic fibers are very significant. In particular, ultra high temperature heating, such as burning temperature in 1538 to 1649 degrees of furnace, the use of refractory fiber energy saving effect is best. Ceramic fiber products (aluminum silicate fiber products) at present, Europe and the United States and Japan all ceramic kiln equipment using ceramic fiber products (aluminum silicate fiber products) lining. Not long ago, Japan will be decomposed into compartments such as gas tunnel kiln structure, and then to the segmented manufacturing factory construction site assembly, all of this is due to the use of ceramic fiber material, greatly saves the cost of more convenient because of the kiln. The research on energy saving effect of ceramic fiber products is also being carried out from the aspects of material modification. Ceramic fiber products (aluminium silicate fiber products)

- Q: What can I do to get the clothes off the ceramic fiber?

- Remove pen marks from clothes easilyFirst of all, the alcohol evenly sprinkled on the pen printed on the pen, alcohol should be used at a concentration of not less than 75% of the alcohol used in medicine. Remember to put on this side of the garment that has been poured down. Do not touch other surfaces of the garment. Otherwise, the color of the pen may be stained with other parts of the garment.Prepare most of the water, and then pour two full bottle of bleach water in the water, stirring, and a little washing powder, so that the laundry powder can be fully dissolved in water. Soak your clothes completely in water for twenty minutes. Washing clothes, there is no mark!Clothes stained with pens, ball pen marks, there is another way to solve: that is, do not rush to the clothes into the water, but first wash with gasoline, washed parts of the re wash.

- Q: Do fiberglass or ceramic fiber paper have insulation effect?

- Second, in the case of temperature can be met, glass fiber cotton insulation better. The main advantage of ceramic fiber is to make gaskets and the like.

- Q: How to paste the ceramic fiber paper on the iron plate?

- Stick on the plate for what you see over the place, or if used in high temperature place, we recommend a special high temperature fireproof glue;

- Q: What's the difference between ceramic fiber paper gasket and ceramic fiber gasket?

- Effect: Although both are high temperature heat insulation gasket, but HLGX ceramic fiber paper on high temperature heat insulation gasket gasket, HLGX ceramic fiber cloth pads are more focused on the high temperature gasket wear resistance and repeated use.

- Q: What fiber glass made of ceramic fiber paper?

- The raw material of the ceramic fiber paper is the ceramic fiber cotton as the basic raw material, and the unique injection process cotton is preferred.

Send your message to us

Ceramic Fiber Paper (1000C-1260C-1350C-1600C)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords