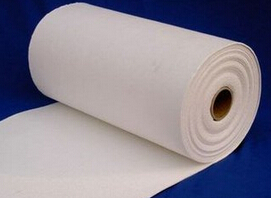

High-Temperature Ceramic Fiber Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of High Temperature Paper

1.Uniform thickness and smooth appearance;

2.Contains no asbestos and anticorrosion; No action with aluminum fluid;

3.Low heat storage;

4.Low thermal conductivity;

5.Good flexibility and toughness and resistance to avulsion;

6.Excellent chemical stability;

7.Excellent machining property;

8.Excellent electric insulation and sound insulation;

9.Excellent thermal shock resistance

Typical Application of High Temperature Paper

1.Appliance heat seals

2.Parting plane in refractory linings

3.Combustion chamber liners

4.Backup lining for metal troughs

5.Hot top linings

6.Thermal and electrical insulation

7.Refractory backup insulation

8.Coke oven door shook absorption medium

9.Kiln car deck covering

Technical Data of High Temperature Paper

Grade | Standard | High Pure | High Aluminium | Zirconium | |||

Max. Temperature (°C) | 1050 | 1150 | 1260 | 1430 | |||

Shrinkage on Heating (%) | 800°C×24h≤-3 | 1000°C×24h≤-3 | 1280°C×24h≤-3 | 1400°C×24h≤-3 | |||

Organic Content (%) | ≤5 | ≤5 | ≤5 | ≤5 | |||

Thermal conductivity by mean temp. (W/m.k.) (250kg/m3) | 200°C | 0.055~0.065 | 0.060~0.070 | ||||

400°C | 0.110~0.120 | 0.105~0.125 | |||||

600°C | 0.160~0.170 | 0.170~0.180 | |||||

Chemical Composition (%) | AL2O3 | 43 | 47 | 55 | 38 | ||

SiO2 | 53 | 51 | 44 | 44 | |||

Fe2O3 + Ti2O3 | ≤1.2 | ≤0.3 | ≤0.3 | ≤0.2 | |||

CaO + MgO | ≤0.3 | ≤0.3 | ≤0.3 | ≤0.2 | |||

NaO + KO2 | ≤0.5 | ≤0.3 | ≤0.3 | ≤0.2 | |||

Density (kg/m3) | 170~230 | ||||||

Size (mm) | Length: 60000/40000/30000/20000/15000/12000 Width: 1220/610 Thickness: 1~6 (Other sizes and shapes on request. ) | ||||||

Package |

Carton box | ||||||

Certificates |

ISO9001-2000; ISO14001-2000 | ||||||

- Q: Which is the best insulation effect of ceramic fiber paper and XPE insulation film?

- The insulation effect depends on the temperature. The same material, the temperature is different, thermal conductivity is not the same. At low temperatures, I suggest you use XPE. Ceramic fiber paper is generally used for hundreds of degrees or even thousands of degrees of high temperature.

- Q: What are the materials for making ceramic fibers?

- The main raw material for the production of ceramic fiber cotton is mainly three two aluminum oxide, and silicon dioxide production process through the silk process, Wuhan, Kyrgyzstan rnd-digital ceramic fiber and ceramic foam with instructions on

- Q: The condition of ceramic glass fiber at high temperature

- This can only say that in general, but there are special circumstances, such as carbon fiber as a special case of ceramic fiber, it can form a fabric, its wide range of applications, from high temperature refractory materials, friction materials, insulation materials, structure of rocket radar stealthy materials to civilian fishing have its place to display.

- Q: How are ceramic fiber papers attached to the interior wall?

- Ceramic fiber paper afraid of water, and no adhesion, putty powder is difficult to hang, it is almost impossible to wallpaper, ceramic fiber paper with ceramic fiber mortar by vacuum filtration process, the surface will remain part of the fiber powder, suggest that you make ceramic fiber paper on the walls of the inner layer. From Ji'nan dragon hot ceramics limited liability company, refractory materials chapter.

- Q: Do ceramic fiber paper smell at high temperature?

- If the ceramic fiber paper in a high temperature environment, the bond will gradually volatile, volatile initial will have a certain odor, and so volatile, there will be no flavor. The binder is a series of organic rubber, and the smell remains as little as possible.

- Q: Where is the best packing area for ceramic fibers?

- As the temperature continues to rise, the products will gradually become white, organic fiber has been completely carbonized products completely for the high temperature inorganic ceramic fiber resistant ceramic fiber (standard type) white maximum temperature ceramic fiber cloth content index color 1260 C fiber diameter 1-4 m thermal shrinkage (1232 C, 24h) 3.5% transmission rate (at 538 8pcf) three 0.130w/m.k two aluminum oxide content 45-48% 0.7-1.2% ferric oxide content of calcium oxide and sodium oxide content of 0.43% slag ball content <8.5% breakdown voltage 5 kv/mm resistance of 5 * 1010 ohm 3w.xxceramic content index white color thickness 1.5mm--6.0mm single 0.5 3kg/ square meters of organic fiber content <20% content <2% strengthening materials alkali glass fiber nichrome wire (1Cr18Ni9Ti)

- Q: What is ceramic fiber paper? What is ceramic fiber paper for?

- In order to understand what ceramic fiber paper can do, it is necessary to know what product characteristics it has. Only by knowing these advantages can we make accurate judgments about what we can do.The ceramic fiber paper is made of ceramic fiber, so the ceramic fiber paper itself contains no asbestos and can replace the carcinogenic asbestos products on the market.The raw material of the ceramic fiber paper is longer, low density, high strength, and has a certain elasticity, so it is easy to carry out stamping, cutting, winding and other construction operations. It is because of the ceramic fiber paper after high temperature firing process, so it has high temperature resistance, chemical corrosion, thermal shock, low thermal conductivity, good dielectric strength and high elastic modulus and high performance.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper?

- Appearance。 The ceramic fiber cloth has an obvious grid like appearance, and the ceramic fiber paper is very few or even mesh like.Density. The density of ceramic fiber paper is greater than that of ceramic fiber cloth.Thickness. Ceramic fiber paper, the thinnest can do 0.5mm, ceramic fiber paper can not do so thin, generally thin, there are also 2mm.Stand upright。 Ceramic fiber paper can be like in our life that can be placed on the A4 paper, mold, stand up. The ceramic fiber cloth is like the cloth used in our life. It is very soft and has no standing.Tear resistance. The toughness of the ceramic fiber paper is not as good as that of the ceramic fiber cloth.

- Q: What's the difference between ceramic fiber paper gasket and ceramic fiber gasket?

- Price: ceramic fiber gasket of the same size and thickness, ceramic fiber paper gasket is lower than ceramic fiber cloth gasket, although both are charged by weight, but the density difference is too big.

- Q: How high is the temperature resistance of the ceramic fiber gasket?

- Ceramic fiber gasket to see what you are using material, usually refers to ceramic fiber paper made of high temperature gasket

Send your message to us

High-Temperature Ceramic Fiber Paper

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords