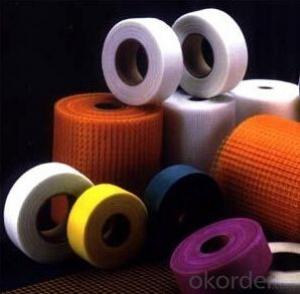

Self Adhesive Fiberglass Mesh Fabric with High Silica Texturized Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

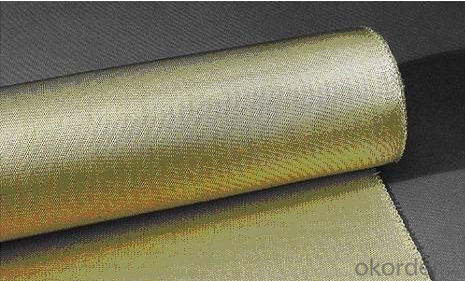

Our Silica Fibre fire Sleeve is an extreme high temperature, heat and flame resistant silica tape, and is an excellent alternative to asbestos and ceramic based textiles. The Silica Fibre Sleeve are primarily used as the thermal protection of circular items, the sleeves can be applied in aerospace (gas turbin and rocket engines), metallurgical, nuclear power, electricity generation, petrochemical industries, etc. for example, tube seals, high temperature gaskets, heaters,reformers,turbine exhaust,boilers, thermocouple wire,etc.

Applifications:

High silica texturized tapes can be used for a long period of time without changing its properties at the temperature of 1000℃,as it contains more than 96% silica.The performance of thermal insulation is excellent because of its texturized structure..

Application:Industrial wires,cables and pipes as thermal insulation material,heat gasket and seal material.

Specification:

| Product Code | SiO2 % | Working Temperature ℃ | Width mm | Thickness | Packing M/Roll |

| TSIP-32-0.8 | ≥94% | 1000 | 32-100 | 0.8 | 10,15,20 |

| TSIP-32-1.0 | ≥94% | 1000 | 32-100 | 1 | 10,15,20 |

| TSIP-32-1.5 | ≥94% | 1000 | 32-100 | 1.5 | 10,15 |

| TSIP-32-2.0 | ≥94% | 1000 | 32-100 | 2 | 10,15 |

| TSIP-32-2.5 | ≥94% | 1000 | 32-100 | 2.5 | 10,15 |

Package and delivery time

Package:Each roll in a polybag,then several rolls in one standard export carton box.

Delivery time:Within 7-15days

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Is fiberglass fabric resistant to water absorption?

- Yes, fiberglass fabric is resistant to water absorption.

- Q: What is the dimensional stability of fiberglass fabric?

- Fiberglass fabric is known for its exceptional dimensional stability. This refers to its ability to maintain its shape and size without significant stretching, shrinking, or warping under various conditions. The dimensional stability of fiberglass fabric is primarily attributed to its composition of fine glass fibers that are woven together to form a tight and uniform structure. The glass fibers used in fiberglass fabric have a high tensile strength, which means they are resistant to stretching or elongation. This property ensures that the fabric retains its original dimensions even when subjected to mechanical stress or tension. Additionally, the glass fibers have a low coefficient of thermal expansion, meaning that they do not expand or contract significantly with temperature changes. This thermal stability helps the fabric maintain its shape and size across a wide range of temperatures. Furthermore, fiberglass fabric is highly resistant to moisture absorption and chemical degradation. Moisture can cause many fabrics to swell or shrink, leading to dimensional changes. However, fiberglass fabric is hydrophobic, meaning it repels water, preventing any significant absorption and subsequent dimensional variations. Moreover, the glass fibers are chemically inert and do not react with most chemicals, making them resistant to chemical degradation that could potentially affect their dimensional stability. Overall, the dimensional stability of fiberglass fabric is excellent, making it a preferred choice in various industries such as aerospace, automotive, construction, and marine. Its ability to maintain its shape, size, and structural integrity under different conditions makes it suitable for applications that require consistent and reliable performance.

- Q: Can fiberglass fabric be used in automotive applications?

- Yes, fiberglass fabric can be used in automotive applications. Fiberglass is a versatile material known for its strength, durability, and heat resistance. It is commonly used in various automotive components such as body panels, hoods, fenders, and interior parts. Fiberglass fabric can be molded into complex shapes and has excellent structural properties, making it suitable for automotive applications where strength and lightweight design are crucial. Additionally, fiberglass fabric can be easily painted and provides a smooth finish, enhancing the aesthetic appeal of automotive parts. Overall, fiberglass fabric is a popular choice in the automotive industry due to its versatility, strength, and ability to meet the demanding requirements of automotive applications.

- Q: Can fiberglass fabric be used for reinforcing plaster or stucco?

- Fiberglass fabric, when used for reinforcing plaster or stucco, can significantly enhance the strength and stability of the surfaces. This durable and robust material is commonly employed in construction projects to prevent cracks and bolster the overall durability of plaster or stucco. Typically, the fiberglass fabric is applied to the surface prior to the application of plaster or stucco, ensuring an even distribution of stress and minimizing the likelihood of cracking or crumbling. Moreover, fiberglass fabric possesses resistance against both moisture and weathering, rendering it an ideal choice for exterior applications, where plaster or stucco may face harsh environmental conditions. Ultimately, the utilization of fiberglass fabric in reinforcing plaster or stucco contributes to the improved structural integrity and longevity of the final surfaces.

- Q: Are fiberglass fabrics resistant to water absorption?

- Yes, fiberglass fabrics are generally resistant to water absorption.

- Q: Can fiberglass fabric be used for seals?

- Yes, fiberglass fabric can be used for seals. Fiberglass fabrics have excellent thermal, chemical, and electrical resistance properties, making them suitable for various sealing applications. They can be used to create gaskets, seals, and insulation materials for a wide range of industries, including automotive, aerospace, marine, and electrical. The high strength and flexibility of fiberglass fabric allow it to conform to irregular surfaces and provide a reliable and durable seal. Additionally, fiberglass fabric is resistant to moisture, oils, and most chemicals, ensuring the longevity and effectiveness of the seals.

- Q: How does fiberglass fabric perform in flexural strength?

- Fiberglass fabric generally exhibits excellent flexural strength due to its inherent properties, such as high tensile strength and rigidity. It can withstand bending or flexing without significant deformation or failure, making it a suitable material for applications that require structural integrity and resistance to bending forces.

- Q: How does fiberglass fabric handle moisture and humidity?

- Fiberglass fabric is highly resistant to moisture and humidity due to its inherent properties. Unlike natural fibers such as cotton or wool, fiberglass is hydrophobic, meaning it repels water and does not readily absorb moisture. This feature allows the fabric to resist mold and mildew growth, making it suitable for use in humid environments. Furthermore, fiberglass fabric does not retain moisture, which prevents it from becoming heavy or sagging when exposed to water or high humidity. This characteristic is especially beneficial in applications where the fabric needs to maintain its strength and shape despite moisture exposure. Additionally, fiberglass fabric is known for its dimensional stability, meaning it does not significantly expand or contract when subjected to changes in humidity levels. This stability ensures that the fabric retains its original shape and size under varying moisture conditions, making it a reliable choice for applications that require consistent performance. Overall, fiberglass fabric's resistance to moisture and humidity makes it a durable and reliable material for a wide range of applications, including boat covers, outdoor furniture, and industrial insulation.

- Q: Can fiberglass fabrics be used for outdoor applications?

- Absolutely! Outdoor applications are perfect for fiberglass fabrics. The durability and ability to withstand harsh weather conditions are what make fiberglass an ideal material for outdoor use. It is commonly seen in outdoor furniture, awnings, canopies, and covers. Moreover, fiberglass fabrics are highly resistant to UV rays, moisture, and mildew, ensuring that they retain their strength and appearance when exposed to the elements. Additionally, their lightweight and flexible nature make fiberglass fabrics a breeze to install and work with for any outdoor project.

- Q: Is fiberglass fabric suitable for use in protective gloves?

- Fiberglass fabric is indeed a suitable option for protective gloves due to its remarkable strength and resistance to heat. This material is perfect for industries dealing with high temperatures or fire hazards. It offers exceptional safeguarding against heat, chemicals, and abrasions. Moreover, fiberglass fabric is both lightweight and flexible, enabling effortless movement and dexterity, which is vital in various work settings. Nevertheless, it is crucial to be aware that fiberglass may cause skin irritation or allergies in certain individuals. Therefore, it is advisable to take necessary precautions, such as wearing a liner glove, to minimize direct contact with the skin.

Send your message to us

Self Adhesive Fiberglass Mesh Fabric with High Silica Texturized Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords