High Silica Fiberglass Fabrics - Good Quality and Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction:

High silica fabrics can be used for a long period of time without changing their properties perat the temperature of 1000℃ as it contains more than 96% silica.

2.Properties

No asbestos orceramic,no harm to human

Low thermal conductivity,excellent thermal insulation,high resistance to thermal shock

Superb electric insulation

Inert to majority of chemical reagents

Good flexibility

3.Application

Aerospace,nuclear

Shipbuilding,machinery industry

Refinery

Metallurgy, auto industry

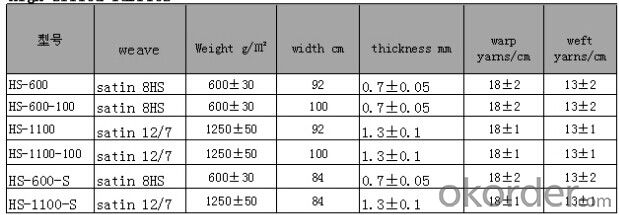

4.Specification

5.Package and Delivery Time.

Packed with carton and pallets.The products will be ready in 15-20 days after the order confirmation.

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Can fiberglass fabrics be used for reinforcement in composites?

- Composites utilize fiberglass fabrics for reinforcement purposes. These fabrics consist of woven or knitted strands of glass fibers, renowned for their remarkable tensile strength and stiffness. They are frequently employed as reinforcing materials during the manufacturing processes of composites. Composites refer to materials created by amalgamating two or more dissimilar materials, resulting in a novel material with enhanced properties. Fiberglass fabrics are typically combined with a matrix material, like epoxy resin, to form a robust and lightweight composite structure. The utilization of fiberglass fabrics as reinforcement in composites offers several benefits. Firstly, they exhibit exceptional durability and mechanical properties, including high tensile strength and stiffness. Consequently, they are suitable for applications necessitating a high strength-to-weight ratio, such as the aerospace, automotive, and marine industries. Furthermore, fiberglass fabrics possess the capability to be easily molded into intricate shapes, making them versatile for various purposes. They also exhibit resistance to corrosion, in addition to possessing commendable thermal and electrical insulation properties. Moreover, fiberglass fabrics can be customized to meet specific design requirements by adjusting the orientation of the fibers, fabric weight, and resin system. This allows for the optimization of strength, stiffness, and other mechanical properties, depending on the intended application. In conclusion, fiberglass fabrics are widely used as reinforcement in composites due to their exceptional strength, lightweight nature, durability, and versatility. They provide numerous advantages and are an indispensable component in the manufacturing of sturdy and lightweight composite structures across various industries.

- Q: Can fiberglass fabrics be used for reinforcement in furniture or fixtures?

- Yes, fiberglass fabrics can be used for reinforcement in furniture or fixtures. The strength and durability of fiberglass make it an excellent choice for adding structural support to various types of furniture and fixtures, ensuring their longevity and stability.

- Q: Can fiberglass fabric be used for insulation in pharmaceutical facilities?

- Yes, fiberglass fabric can be used for insulation in pharmaceutical facilities. It is a commonly used material due to its excellent thermal insulation properties, fire resistance, and ability to withstand high temperatures. Additionally, it is lightweight, durable, and cost-effective, making it suitable for various applications in pharmaceutical facilities.

- Q: Can fiberglass fabric be used for making backpacks or luggage?

- Yes, fiberglass fabric can be used for making backpacks or luggage. Fiberglass fabric is known for its strength and durability, making it an excellent choice for creating sturdy and long-lasting bags. It is lightweight, resistant to tear and abrasion, and can withstand heavy loads. Additionally, fiberglass fabric is often used in industries where strength and durability are essential, such as aerospace and automotive, further highlighting its suitability for backpacks and luggage. However, it is worth noting that fiberglass fabric may not be as flexible or moldable as other materials, so it may be more suitable for rigid or structured bag designs rather than soft or collapsible styles.

- Q: What are the environmental considerations of using fiberglass fabric?

- Some of the environmental considerations of using fiberglass fabric include the potential release of hazardous chemicals during production, the energy-intensive manufacturing process, and the difficulty of recycling fiberglass materials. Additionally, fiberglass fabric is not biodegradable and can contribute to landfill waste if not properly disposed of. Overall, the use of fiberglass fabric raises concerns regarding its environmental impact and sustainability.

- Q: What is the typical width of fiberglass fabrics?

- The typical width of fiberglass fabrics can vary depending on the specific application and manufacturer. However, standard widths for fiberglass fabrics range from 36 to 60 inches (91-152 cm). These widths are commonly used in industries such as aerospace, automotive, construction, and marine. It is important to note that custom widths can also be produced for specific requirements if needed.

- Q: Is fiberglass fabric resistant to chemicals in automotive fluids?

- Yes, fiberglass fabric is generally resistant to chemicals found in automotive fluids. Fiberglass itself is a highly durable and versatile material that is known for its resistance to a wide range of chemicals, including those typically found in automotive fluids such as gasoline, diesel, oil, and antifreeze. It is commonly used in automotive applications where resistance to chemicals is required, such as in the production of gaskets, seals, and insulation materials. However, it is important to note that the specific chemical resistance of fiberglass fabric can vary depending on the type of resin used in its production and the specific composition of the automotive fluid. Therefore, it is always recommended to consult the manufacturer's specifications or conduct compatibility tests to ensure the optimal performance of fiberglass fabric in contact with automotive fluids.

- Q: Is fiberglass fabric suitable for making protective clothing?

- Yes, fiberglass fabric is suitable for making protective clothing. Fiberglass fabric is known for its excellent heat resistance and flame retardant properties, making it an ideal choice for protective clothing in industries where workers are exposed to high temperatures, sparks, and flames. The fabric is also lightweight and durable, providing comfort and long-lasting protection. Furthermore, fiberglass fabric has good insulation properties, protecting the wearer from extreme cold or hot environments. It is also resistant to chemicals, making it suitable for use in industries where workers are exposed to hazardous substances. However, it is important to note that fiberglass fabric can irritate the skin and cause respiratory issues if not properly handled or sealed, so proper precautions should be taken when working with this material.

- Q: What is the typical lead time for ordering fiberglass fabrics?

- Lead times for ordering fiberglass fabrics can vary depending on various factors. Typically, the range can span from a few days to a few weeks. The availability of the specific fiberglass fabric you require is the first factor that influences lead time. Some types may be readily accessible in stock, while others might necessitate manufacturing or importing, thereby increasing the lead time. The quantity of fiberglass fabric you order is another factor. Larger orders may necessitate additional time for production and processing, particularly if customization or specific dimensions are required. Furthermore, the supplier's location can impact lead time. If the supplier is situated far from your location, the shipment and delivery of the fabrics may take longer. It is also crucial to consider potential delays that may arise during the shipping process, such as customs clearance or unforeseen transportation issues. For a more accurate estimation of the lead time for ordering fiberglass fabrics, it is advisable to directly contact the supplier. They can provide specific information based on their inventory, production capabilities, and shipping options.

- Q: Is fiberglass fabric flame resistant?

- Yes, fiberglass fabric is flame resistant.

Send your message to us

High Silica Fiberglass Fabrics - Good Quality and Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000kg kg

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords