HIGH QUALITY GB STANDARD HOT ROLLED ANGLE BAR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Hot Rolled Steel Rebar:

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Hot Rolled Steel Rebar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

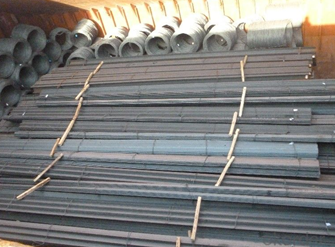

Packaging & Delivery of Hot Rolled Steel Rebar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Q235

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: Can steel angles be used for modular furniture or fixtures?

- Certainly, modular furniture or fixtures can definitely utilize steel angles. These robust and adaptable structural components can be seamlessly incorporated into the design of modular furniture. They contribute stability and reinforcement to the overall structure, resulting in furniture pieces that are not only resilient but also long-lasting. Steel angles can serve as corner brackets or supports for shelves, cabinets, or other modular elements. They can be effortlessly tailored to meet specific design criteria through cutting, welding, or drilling, thus granting the freedom to create various configurations or sizes of modular furniture. Furthermore, steel angles can be powder coated or painted in a variety of colors to match the desired visual appeal of the furniture or fixtures. The utilization of steel angles in modular furniture or fixtures guarantees durability and longevity. They exhibit resistance to wear and tear, corrosion, and impact, rendering them suitable for both indoor and outdoor applications. Additionally, steel angles are readily available and cost-effective, making them a pragmatic choice for the manufacturing of modular furniture or fixtures. To summarize, steel angles are an outstanding option for the creation of modular furniture or fixtures due to their potency, versatility, and endurance. They lend stability and support to the structure, can be conveniently tailored, and deliver sustained performance. Whether for residential or commercial purposes, steel angles can be employed to fashion modular furniture or fixtures that are both functional and visually appealing.

- Q: How do steel angles contribute to the sustainability of transportation systems?

- Several ways contribute to the sustainability of transportation systems through the utilization of steel angles. To begin with, steel angles find wide use in constructing infrastructure, such as bridges, highways, and railway tracks. These structures boast a longer lifespan and necessitate fewer repairs and replacements compared to alternative materials. As a result, maintenance costs and resource consumption are reduced. Furthermore, steel angles possess exceptional durability and resistance to severe weather conditions. This quality ensures the longevity and safety of transportation systems. Consequently, the need for frequent repairs or replacements is minimized, thereby decreasing the overall environmental impact and carbon emissions associated with transportation infrastructure. In addition, steel angles possess a high strength-to-weight ratio, enabling the design of lighter and more fuel-efficient vehicles. Utilizing steel angles in the manufacturing process of automobiles, trains, and ships leads to reduced vehicle weight, thereby enhancing fuel efficiency and decreasing greenhouse gas emissions during operation. Moreover, steel angles can be easily recycled at the end of their lifecycle. Globally, steel is one of the most recycled materials, boasting a recycling rate of over 85%. By recycling steel angles, not only is the demand for virgin steel production reduced, but energy is also saved, and greenhouse gas emissions associated with extraction and manufacturing processes are decreased. Overall, the incorporation of steel angles in transportation systems promotes sustainability by fostering durability, decreasing maintenance needs, improving fuel efficiency, and enabling efficient recycling. These factors collectively contribute to minimizing the environmental impact and enhancing the long-term viability of transportation infrastructure.

- Q: How are steel angles defined?

- Steel angles are defined by their shape and dimensions. They are L-shaped structural members made of steel with two perpendicular legs of equal or unequal lengths. The angle between the legs can range from 90 to 180 degrees, depending on the specific design and application. Steel angles are commonly used in construction and engineering projects to provide structural support, reinforcement, and stability. The dimensions of steel angles are typically specified by their leg length, thickness, and overall length. These dimensions determine the strength, load-bearing capacity, and versatility of the angle, making it suitable for various applications in different industries. Steel angles are also available in various finishes, such as galvanized or painted, to enhance their durability and resistance to corrosion.

- Q: Can steel angles be used for transmission towers?

- Yes, steel angles can be used for transmission towers. Steel angles provide structural strength and support, making them suitable for constructing transmission towers that need to withstand various weather conditions and carry heavy loads.

- Q: What are the different specifications for steel angles?

- Steel angles, also known as angle irons or L-shaped bars, are versatile structural components used in various industries. They are characterized by their L-shaped cross-section, with two legs of equal or unequal length. Steel angles have different specifications based on their dimensions, material composition, and manufacturing standards. 1. Dimensions: Steel angles are specified by their leg lengths (L1 and L2) and thickness (T). The leg lengths can vary from equal angles (L1 = L2) to unequal angles (L1 ≠ L2). Common leg lengths range from 20mm to 200mm, while thicknesses typically range from 3mm to 20mm. 2. Material Composition: Steel angles are typically made from carbon steel, which offers strength and durability. The specific grade of carbon steel used depends on the application and required mechanical properties. Common grades include A36, A572, and A588. 3. Manufacturing Standards: Steel angles are produced according to various manufacturing standards, which ensure quality and consistency. Some common standards include ASTM (American Society for Testing and Materials), EN (European Norms), and JIS (Japanese Industrial Standards). These standards define the chemical composition, mechanical properties, and tolerances for steel angles. 4. Surface Finish: Steel angles can have different surface finishes, depending on the application and aesthetic requirements. Common finishes include hot-dip galvanized, painted, or mill finish (raw steel). Galvanized angles are coated with a layer of zinc for corrosion protection, while painted angles add an additional layer of protection and can be customized in terms of color. 5. Tolerances: Steel angles have specific tolerances that define acceptable deviations from the specified dimensions. These tolerances ensure that the angles meet the required standards and can be used in structural applications. Tolerances can vary based on the manufacturing standard and the specific dimensions of the angle. In summary, the different specifications for steel angles include dimensions (leg lengths and thickness), material composition (carbon steel grades), manufacturing standards (ASTM, EN, JIS), surface finish (galvanized, painted, mill finish), and tolerances. These specifications allow for the selection of the appropriate steel angle for a particular application, ensuring structural integrity and performance.

- Q: What are the different types of steel angles connections for beams?

- Beams can be connected using various types of steel angle connections. Some commonly used types include: 1. Bolted connections: The most frequently used connection for steel beams involves securing steel angles to the beams using bolts. Typically, the angles are attached to the beam flanges, providing extra support and stability. 2. Welded connections: Welding techniques are employed to connect steel angles to the beams. This type of connection is preferred when high strength and rigidity are necessary. Although more costly and time-consuming than bolted connections, welded connections offer superior strength and durability. 3. Clip angles: Small angles called clip angles are utilized to connect beams to other structural elements like columns or walls. These angles are usually bolted or welded to the beams, providing additional support and stability. 4. Gusset plates: Thick steel plates known as gusset plates are used to connect beams at their intersection points. These plates are typically bolted or welded to the beams, enhancing strength and rigidity. 5. Shear plates: Shear plates, similar to gusset plates, are specifically designed to resist shear forces. Usually bolted or welded to the beams, these plates offer additional shear resistance and stability. These examples showcase the various types of steel angle connections that can be employed for beams. The choice of connection depends on factors such as the specific application, load requirements, and structural design considerations.

- Q: What is the typical thickness of a steel angle?

- The specific application and the desired strength are factors that can cause the typical thickness of a steel angle to vary. Generally, steel angles are offered in various thickness options, ranging from 1/8 inch (3.18 mm) to 3/4 inch (19.05 mm) or greater. Determining the appropriate thickness involves considering aspects like load-bearing necessities, structural design, and the desired durability level.

- Q: What are the different grades of steel used for manufacturing steel angles?

- The different grades of steel used for manufacturing steel angles include A36, A572, A588, and A992.

- Q: Are steel angles resistant to dynamic loads?

- Generally, steel angles exhibit resistance to dynamic loads. Steel is a durable and robust material that can withstand a variety of loads, including those that change in magnitude or direction over time, such as impact loads, vibrations, or seismic forces. Steel angles, which are also referred to as angle irons or L-shaped structural steel, find widespread use in the construction, engineering, and manufacturing industries due to their high strength-to-weight ratio and versatility. They effectively distribute and transfer loads, providing stability and support to structures. The resistance of steel angles to dynamic loads can be attributed to their inherent properties, including high tensile strength, excellent ductility, and toughness. These properties enable steel angles to absorb and dissipate energy from dynamic loads, thereby minimizing the risk of structural failure or damage. Furthermore, steel angles can be reinforced through various methods, such as welding, bolting, or bracing, to further enhance their resistance to dynamic loads. By employing these reinforcement techniques, steel angles can be customized to meet specific dynamic load requirements, ensuring the integrity and safety of the overall system. However, it is important to consider that the resistance of steel angles to dynamic loads may be influenced by several factors. These factors include the specific grade and quality of the steel, the dimensions and configuration of the angle, the magnitude and frequency of the dynamic loads, and the overall design and construction of the structure. It is, therefore, crucial to consult with structural engineers and adhere to relevant building codes and standards to select and implement steel angles appropriately for dynamic load applications.

- Q: Are steel angles suitable for agricultural applications?

- Yes, steel angles are suitable for agricultural applications. Steel angles are versatile and durable, making them ideal for various agricultural purposes. They can be used for constructing sturdy frames for greenhouses, barns, and storage buildings. Steel angles provide excellent structural support and can withstand heavy loads, making them suitable for building sturdy fences, gates, and livestock enclosures. Additionally, steel angles are resistant to corrosion, which is crucial in agricultural environments where exposure to moisture and chemicals is common. The versatility and durability of steel angles make them a reliable choice for agricultural applications.

Send your message to us

HIGH QUALITY GB STANDARD HOT ROLLED ANGLE BAR

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords