High Quality Aluminum Wall Sheets for Electric Shells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

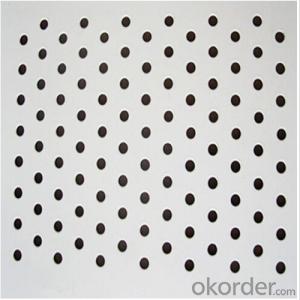

Aluminum sheet checkered /Aluminum sheet embossing sheet

| Material | 1000 series: 1050. 1070. 1100 2025. 2117. 2218. 2618. 6000 series: 6005. 6011. 6053. 6351. 6061. 6101. 6151. 6201. 6261. 6262. 6063. 6463. 6066.6070 7000series: 7001. 7005. 7072. 7075. 7076. 7175. 7178. 7079 8000 series:8011,8021,8079 etc |

| Standard | GB/T17748-2008 |

| Certification | ISO9001,ISO14001, ISO9001:2000 |

| Temper | T4,T5,T6,H111,H112 |

| Surface treatment | Polished,Mill Finished,anodized or power sprayed |

| Features | High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness |

| Resolution | 2%-98% |

| Advantages | 1)Excellent machining properties 2)Suited to marine and low temp applications |

| Note | If you have any other questin,welcome for your consultation |

1)Chemical compositions&mechanical property&Size

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.50-1.10 | 0.10 | 0.25 | - | spare |

5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | spare | |

5083 | 0.40 | 0.40 | 0.10 | 0.40-1.0 | 4.0-4.9 | 0.05-0.25 | 0.25 | 0.15 | spare |

6060 | 0.30 -0.6 | 0.10 -0.30 | ≤0.10 | ≤0.10 | 0.35~0.6 | ≤0.05 | ≤0.15 | ≤0.10 | spare |

Packaging & Shipping

Package: Standard seaworthy packing or as per request

Transports:Containler sizes:

20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)

40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)

Our Services

1 Customer and reputation first

2 Timely feedback

3 Low MOQ

4Timely delivery

5 Competitive price

6Different size can be supplyed as your request

7 Professional service of technical and shipping support

8More than 30 years experience in the cold and hot rolled sheet/coil/stri experience

Photos

- Q: What is the typical machinability of aluminum sheets?

- The typical machinability of aluminum sheets is considered to be excellent. Aluminum is known for its softness and low density, which makes it relatively easy to machine. It can be cut, drilled, and formed with relative ease, allowing for efficient and precise machining processes. However, the specific machinability of aluminum sheets can vary depending on factors such as alloy composition, temper, and thickness.

- Q: How do aluminum sheets perform in extreme temperatures?

- Known for their excellent performance in extreme temperatures, aluminum sheets possess a high melting point of around 660 degrees Celsius, enabling them to endure high temperatures without deforming or melting. In situations of intense heat, aluminum sheets exhibit a low thermal expansion rate, ensuring minimal expansion or contraction, thus guaranteeing dimensional stability. Consequently, they prove to be highly suitable for utilization in industries such as aerospace, automotive, and construction, where extreme temperatures commonly prevail. Similarly, even in severely cold temperatures, aluminum sheets maintain their strength and durability, unlike certain other metals that become brittle and susceptible to cracking. Additionally, aluminum boasts exceptional thermal conductivity, facilitating the even distribution of heat, which proves advantageous in applications where efficient heat dissipation is of paramount importance. All in all, aluminum sheets demonstrate exceptional performance in extreme temperatures, establishing themselves as a dependable choice for a variety of industries.

- Q: Are the aluminum sheets suitable for manufacturing electronics components?

- Absolutely, aluminum sheets are a perfect fit for the production of electronic components. Aluminum, being a lightweight, durable, and reasonably priced material, finds extensive usage in the electronics sector. Its remarkable electrical conductivity is crucial for the efficient operation of electronic devices. Moreover, aluminum sheets can effortlessly be molded, trimmed, and fashioned into diverse components like heat sinks, enclosures, and connectors. Furthermore, aluminum boasts commendable thermal conductivity, enabling it to proficiently disperse heat generated by electronic components. Consequently, aluminum sheets emerge as an optimal selection for the manufacturing of electronic components.

- Q: Are aluminum sheets suitable for signage and advertising?

- Yes, aluminum sheets are suitable for signage and advertising. They are durable, weather-resistant, and can be easily customized with graphics and text. Additionally, their sleek and professional appearance makes them an excellent choice for promotional materials, outdoor signs, and indoor displays.

- Q: 1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- Al is not reactive because it is so reactive - it gets coated with oxide immediately on exposure, the oxide layer is strong and quite inert except to strong acids.

- Q: Can aluminum sheets be used for reflective surfaces?

- Yes, aluminum sheets can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it an excellent material for creating reflective surfaces. Due to its smooth and highly polished finish, aluminum sheets can effectively reflect light, heat, and other forms of radiation. This property makes them suitable for a wide range of applications, including solar panels, mirrors, lamp reflectors, and reflective insulation. The use of aluminum sheets as reflective surfaces is advantageous due to their durability, lightweight nature, and resistance to corrosion.

- Q: 1. Why does aluminium resist corrosion?2. How do we make aluminium stronger?3. Why does titanium resist corrosion?4. What properties make titanium ideal to use in jet engines and nuclear reactors?5. Why do we need electricity to make aluminium and titanium?6. Why does recycling aluminium save electricity?Even if you only know the answer to one question the help will be much appreciated :D

- 1. When exposed to air, pure aluminium rapidly forms a passive oxide layer, alumina, which further inhibits aluminium reactions with other elements. 2. Aluminium can be made stronger by alloying with other elements. One of the most known aluminum alloy is duraluminium, where the principal alloying component is copper. 3. Exactly as aluminium, titanium corrosion resistance is due to its high reactivity with oxygen. When pure titanium is exposed to air it forms a passive titanium dioxide layer on the surfaces exposed which further prohibits other reactions with corrosion agents. 4. The use of titanium in jet engines components is favored by its strength to weight ration, which is unmatched by any other metal. As for the nuclear reactors, its use is preferred because of its superior corrosion resistance associated with fracture toughness and overall durability. 5. Both titanium and aluminium are refined from their respective mined ores - bauxite, for aluminium, ilmenite and rutile for titanium. Basically, these are oxides of the metals. Pure metal has to be reduced from these ores and processes involve use of temperatures up to and sometime exceeding 1000 degrees Celsius, which obviously requires a great consumption of energy, including electricity. Moreover, pure aluminium is obtained in the final processing phase through electrolysis, meaning an electrical current is needed in order to drive the required chemical reactions, thus adding to the electrical consumption. 6. Recycling aluminium from aluminium simply requires the remelting of the metal, eliminating the electrolytic phase that is high electric energy consuming.

- Q: How does the thickness of aluminum sheet affect its strength?

- The thickness of an aluminum sheet directly affects its strength. In general, a thicker sheet of aluminum will be stronger than a thinner one. This is because the thickness of the sheet determines the amount of material present, which in turn affects the sheet's ability to withstand external forces or loads. The strength of a material is typically measured by its ability to resist deformation or failure under stress. Thicker aluminum sheets have a greater volume of material, which means there are more atoms and bonds available to withstand forces. This results in a higher resistance to deformation or failure, making the sheet stronger. Additionally, a thicker aluminum sheet also has a higher load-bearing capacity. This means it can support heavier loads or withstand higher pressures without deforming or failing. The increased thickness provides more material to distribute the load, reducing the stress on individual atoms and bonds within the sheet. However, it is important to note that there is a limit to the thickness at which the strength of the aluminum sheet plateaus. Beyond a certain point, further increasing the thickness may not significantly improve its strength. This is because the material properties of aluminum, such as its crystal structure and grain boundaries, also play a role in determining its strength. In conclusion, the thickness of an aluminum sheet directly affects its strength. Thicker sheets have more material, enabling them to resist deformation or failure under stress more effectively. This increased thickness also allows them to support heavier loads or withstand higher pressures. However, there is a limit to the thickness at which the strength plateaus, as other material properties come into play.

- Q: Are the aluminum sheets suitable for manufacturing power distribution panels?

- Absolutely, power distribution panels can be manufactured using aluminum sheets. Aluminum is an exceptional material choice for various industrial applications, including power distribution panels, due to its lightweight, durability, and resistance to corrosion. Not only can aluminum sheets effectively handle high electrical currents, but they also efficiently dissipate heat, ensuring a safe and efficient power distribution system. Furthermore, aluminum is widely accessible and cost-effective in comparison to alternatives like copper. Consequently, aluminum sheets are an excellent option for manufacturing power distribution panels.

- Q: What are the different types of surface coatings for aluminum sheets?

- There are several types of surface coatings available for aluminum sheets, including anodizing, powder coating, painting, and laminating.

Send your message to us

High Quality Aluminum Wall Sheets for Electric Shells

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords