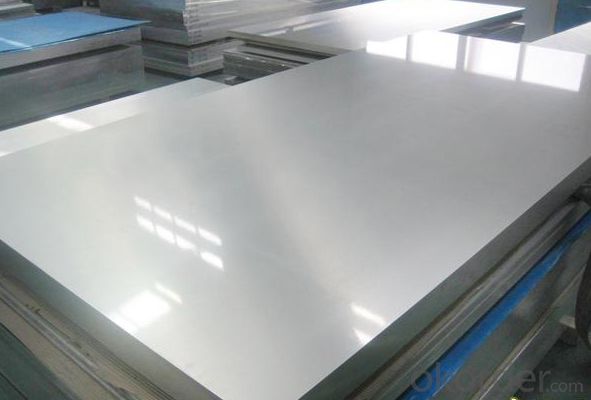

High Quality Aluminum Sheets for Photo Printing with Width up to 2620mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

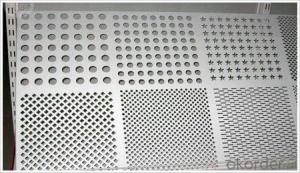

Pattern: orange peel, aluminum sheet5 bar,half a ball,diamond,compass shape

1.Orange peel aluminum sheet/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052

2)Temper :0 H114 H24 H32

3) Specification thickness:0.2mm-3.0mm

width:50mm-1300mm

Length: according your request

4)Application: Refrigeration. Air-conditioner. keep warm well such as pipe ,tank

5)Surface: No crack,canker, hole

2. aluminum sheet5 bar/coil

1)Alloy :1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

3.Compass shape aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: thickness:1.0mm-10mm

width:50mm-2000mm

Length: according your request

4)Application: the main function is anti-skidding,widely used in automobile manufacturing,shipbuilding,machine manufacturing,elerator,workshop

5)Surface: No crack,canker, hole

4.Diamond aluminum sheet/coil

1)Alloy:1060 1100 1050 3003 3004 3105 5052 5754 5083 6061 6063 6082

2)Temper: O H114 H194 T6

3) Specification: Thickness:1.0mm-10mm

Width:50mm-2000mm

Length: according your request

4)Application: building industry,packing,decorative

5)Surface: No crack,canker, hole

4) Delivery time: 15-20 days after confirming order.

For all above:

1) Minimum order quantity: 5 tons per size.

2) The term of payment: T/T, irrevocable L/C at sight.

3) Packing: Export standard, waterproof wooden,craft,plywood pallet,etc.

- Q: This question asks for methods to guarantee that the edges of installed aluminum sheets remain straight and smooth.

- <p>To ensure that the edges of aluminum sheets are straight and smooth after installation, follow these steps: 1. Use high-quality aluminum sheets that are free from warping or defects. 2. Measure and cut the sheets accurately to avoid any discrepancies. 3. Use a sharp, clean cutting tool to prevent jagged edges. 4. Smooth out any rough edges with a file or sandpaper. 5. Install the sheets with precision, ensuring they are aligned properly. 6. Use appropriate fasteners and brackets to secure the sheets without causing any distortion. 7. Regularly inspect and maintain the sheets to address any issues promptly. By following these steps, you can maintain the straightness and smoothness of aluminum sheet edges after installation.</p>

- Q: I'm trying to use as little aluminum as possible as it can be related to health problems, and I'm just trying to be a little more careful. I just bought the Emerilware pro-clad pot and pan set, and it's stainless steel but says Emerilware Pro-Clad is constructed with an aluminum core bonded between two layers of stainless steel ideal for... Therefore, I'm still cooking with aluminum. Is it safer since it's between 2 pieces of stainless steel? Does any stainless steel cookware not use aluminum? Thanks.

- First of all, there is no link between health problems and aluminum. Years ago, they thought there might be a link between alzheimer's and aluminum, but that has since been disproved. Secondly, stainless steel is a poor conductor of heat. But the stainless is a great, sturdy, non-reactive metal to use for cookware. So they add aluminum or copper to it's core to help it heat properly. Copper will cost you an arm and a leg, so all other cookware uses aluminum. If you had stainless cookware with no aluminum, it would take you an hour to boil water and your food would cook terribly unevenly. The outsides would burn before the inside cooked. So no, you won't find stainless without aluminum unless it's copper cored. But again, aluminum will do you no harm. You wrap your food in tin foil, which is aluminum. You eat food that has been sitting in aluminum cans on the shelf for god knows how long. And the anti-perspirant you use every morning? Check the ingrediants. Aluminum. Right on your lymph nodes. Stop worrying. Still worrying? aluminum is basically poreless. No aluminum will leach through. You are safe.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- The aluminum oxide that forms adheres to the metal surface explains aluminum's resistance to corrosion. Aluminum naturally forms a protective oxide film, which is stable in aqueous media when the pH is between about 4.0 and 8.5. The oxide film is naturally self-renewing and accidental abrasion or other mechanical damage of the surface film is rapidly repaired. The conditions that promote corrosion of aluminum and its alloys, therefore, must be those that continuously abrade the film mechanically or promote conditions that locally degrade the protective oxide film and minimize the availability of oxygen to rebuild it.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when utilizing aluminum sheets in conjunction with concrete, there are several precautionary measures that can be employed: 1. Barrier Coating: Apply a protective barrier coating or paint onto the aluminum sheets to create a separation between them and the concrete. This coating functions as a safeguarding layer, hindering direct contact between the aluminum and the concrete, thereby diminishing the likelihood of galvanic corrosion. 2. Insulation: Introduce an insulating material between the aluminum sheets and the concrete. This material can take the form of a non-conductive plastic or rubber sheet that effectively isolates the aluminum from the concrete, minimizing the potential risk of galvanic corrosion. 3. Surface Treatment: Administer a corrosion-resistant treatment to the aluminum sheets. Anodizing is a prevalent surface treatment technique that generates a protective oxide layer on the aluminum surface, augmenting its resistance to corrosion when in contact with concrete. 4. Utilize Dissimilar Metals: Refrain from employing dissimilar metals in conjunction with aluminum sheets and concrete. When dissimilar metals, such as steel or iron, come into contact with aluminum in the presence of moisture, the likelihood of galvanic corrosion increases. Hence, it is advisable to employ aluminum fasteners or supports when working with aluminum sheets and concrete. 5. Adequate Drainage: Ensure proper drainage in areas where aluminum sheets are in contact with concrete. Accumulation of water or moisture can expedite galvanic corrosion. By ensuring sufficient drainage, the amount of moisture that comes into contact with the aluminum can be minimized, thereby reducing the risk of corrosion. 6. Routine Maintenance: Regularly inspect and maintain the aluminum sheets and their protective measures. If any damage or deterioration is detected, promptly repair or replace the barrier coatings, insulation, or surface treatments to ensure continuous protection against galvanic corrosion. By implementing these preventative measures, the risk of galvanic corrosion when employing aluminum sheets with concrete can be significantly mitigated, thereby prolonging the longevity and integrity of both the aluminum and the concrete structures.

- Q: Are aluminum sheets suitable for insulation and soundproofing?

- Yes, aluminum sheets can be suitable for insulation and soundproofing purposes. Aluminum is a lightweight, durable, and highly reflective material that can effectively block heat and sound transmission. When used as insulation, aluminum sheets can act as a radiant barrier, reflecting heat away from the insulated space and helping to maintain a comfortable temperature. Furthermore, aluminum sheets can also be used as a soundproofing material to reduce the transmission of noise. The dense structure of aluminum helps to absorb and dampen sound waves, making it an effective solution for minimizing noise pollution. Additionally, aluminum sheets are resistant to corrosion and moisture, making them suitable for both indoor and outdoor applications. Overall, aluminum sheets provide a cost-effective and efficient solution for insulation and soundproofing needs.

- Q: What the glue of L solidified aluminum and fast acrylic plate, solid glue?

- Aluminum and acrylic adhesive, if you want to achieve high strength without any effect, can be bonded with KD-5603 trace glue, but this should be with the help of UV curing light curing, if there is no UV curing light, the sun is strong weather, stick in the sun after 30 minutes can be the bonding effect of glass panel; the specific effects can refer to the general glass coffee table with four Aluminum Alloy column, don't see any traces of adhesive;

- Q: What are the different methods for joining aluminum sheets?

- There are several methods for joining aluminum sheets, depending on the specific application and desired outcome. Some of the common methods include: 1. Welding: Aluminum can be welded using various techniques such as Tungsten Inert Gas (TIG) welding, Metal Inert Gas (MIG) welding, and Resistance Spot Welding (RSW). TIG welding is commonly used for thin aluminum sheets, providing a strong and precise joint. MIG welding is suitable for thicker sheets and offers faster production rates. RSW involves passing an electric current through the sheets, melting the aluminum at the contact points, and then applying pressure to create a solid joint. 2. Mechanical Fasteners: Bolts, nuts, and screws can be used to join aluminum sheets together. They provide a strong and reliable connection that can be easily disassembled if needed. Rivets are another common mechanical fastening method, where a rivet gun is used to secure the sheets by deforming the rivet. 3. Adhesive Bonding: Specialized adhesives designed for aluminum bonding can be used to join sheets together. This method is often used when aesthetics are important, as it provides a clean and seamless appearance. Adhesive bonding also distributes the stress evenly across the joint, reducing the risk of localized stress concentration. 4. Clinching: Clinching is a cold joining process where a punch is used to deform the aluminum sheets, creating a mechanical interlock. This method is quick, cost-effective, and does not require additional materials like fasteners or adhesives. 5. Friction Stir Welding (FSW): FSW is a solid-state joining process that uses a rotating tool to generate friction between the aluminum sheets. The friction heats the material, making it pliable, and the rotating tool then stirs the softened material together to form a solid joint. FSW is particularly suitable for joining thicker aluminum sheets. Each joining method has its own advantages and disadvantages, and the choice depends on factors such as the desired strength, appearance, production rate, and the specific requirements of the application.

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: Can aluminum sheets be used for aircraft manufacturing?

- Indeed, aircraft manufacturing commonly utilizes aluminum sheets. This lightweight and corrosion-resistant material proves to be an excellent option for crafting diverse aircraft components. Its strength allows it to endure the pressures and tensions experienced during flight, while its malleability enables it to take on various forms and sizes. Moreover, aluminum sheets can be effortlessly joined together using diverse welding techniques, facilitating efficient and effective assembly of aircraft structures. Consequently, the utilization of aluminum sheets in aircraft manufacturing ensures a harmonious combination of strength, weight, and durability, rendering it a favored material in the aerospace sector.

- Q: Can 101 aluminum sheets be anodized in different colors?

- Indeed, it is possible to anodize 101 aluminum sheets in various hues. Anodization entails generating an oxide coating on the aluminum's surface, which can then be dyed to attain a plethora of colors. The quantity of sheets, in this instance 101, does not impede the capacity to anodize them in distinct shades. Every sheet can be anodized and dyed separately to produce a distinct and preferred color. Anodization is a versatile procedure that facilitates customization and color diversity, enabling the achievement of diverse tones and tints on each individual aluminum sheet.

Send your message to us

High Quality Aluminum Sheets for Photo Printing with Width up to 2620mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords