High Quality Aluminum Coils - Mill Finished Aluminum Treadplate with Big Five Bar Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Mill Finished Aluminium Treadplate of Big Five Bar Pattern Description

Mill Finished Aluminium Treadplate of Big Five Bar Pattern is one semi-finished aluminium material. This coil can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

Mill Finished Aluminium Treadplate of Big Five Bar | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

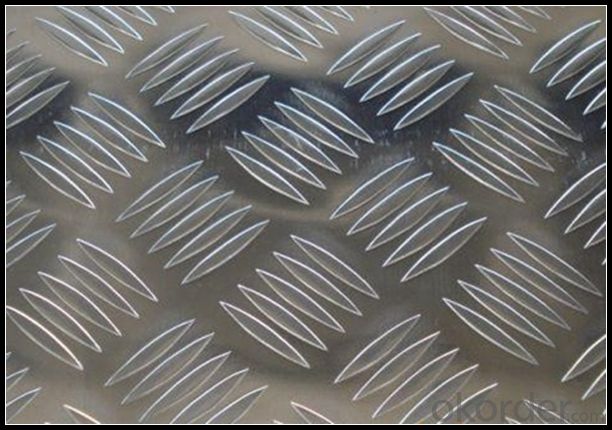

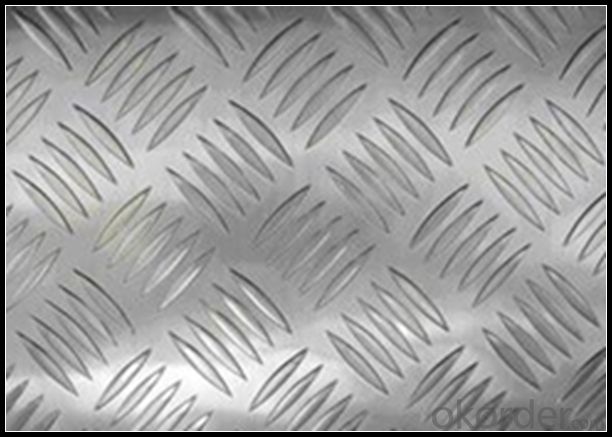

6. Image of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

7. Package and shipping of Mill Finished Aluminium Treadplate of Big Five Bar Pattern

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How to deal with too much aluminum powder in aluminum striping?

- Currently, there are bag dust-removal system and water dust-removal system. The former is very popular with enterprises because of low maintenance cost, accounting for over 90%. But the problem is the dust accumulation because the ventilation and dust removal systems are not produced in strict accordance with the standard. For example, controlling wind speed does not meet the requirement; ventilation and dust removal system does not meet the requirements of explosion-proof, including the set of pipes, series and parallel connection, the choice of dust removal system, the spark detection and extinguishing measures.

- Q: What are the potential applications of coil-brushed aluminum coils?

- Due to its unique properties, coil-brushed aluminum coils have a wide range of potential applications. Here are several examples: 1. Architectural projects can benefit from the use of coil-brushed aluminum coils. These coils can be utilized for building facades, roofing, cladding, and decorative elements, adding a sophisticated and modern look to structures. 2. In the field of interior design, coil-brushed aluminum coils can be used for wall paneling, ceiling tiles, partition screens, and decorative accents. The brushed texture provides a sleek and stylish appearance, making them suitable for residential, commercial, and hospitality settings. 3. Coil-brushed aluminum coils can be incorporated into furniture designs, including tables, chairs, shelves, and cabinets. The brushed finish adds a contemporary touch to the furniture pieces, making them suitable for modern and minimalist styles. 4. The lightweight and corrosion-resistant nature of aluminum make it an ideal material for automotive applications. Coil-brushed aluminum can be used in the manufacturing of interior trim, dashboards, door panels, and other decorative components in cars, trucks, and motorcycles. 5. The excellent conductivity and heat dissipation properties of coil-brushed aluminum make it suitable for the production of electronic devices such as smartphones, laptops, and tablets. The brushed finish adds a premium feel to these products. 6. Coil-brushed aluminum coils are also useful in the manufacturing of signage and branding elements. The brushed texture enhances the visibility and aesthetics of the signs, making them stand out and convey a sense of quality and professionalism. 7. In the kitchenware and appliances industry, coil-brushed aluminum is a popular choice due to its durability, heat resistance, and easy cleaning properties. It can be used to produce cookware, bakeware, kitchen utensils, and appliance panels, providing a sleek and modern look. 8. Coil-brushed aluminum coils are also utilized in the production of packaging and labeling materials. The brushed finish adds an elegant touch to product packaging, making it visually appealing and attractive to consumers. In conclusion, coil-brushed aluminum coils have a wide range of potential applications in various industries, including architecture, interior design, automotive, electronics, kitchenware, signage, and packaging. Their unique properties make them versatile and desirable for different projects.

- Q: What is the maximum coil weight for aluminum coils?

- The maximum coil weight for aluminum coils can vary depending on various factors such as the thickness and width of the coil, as well as the specific alloy being used. Generally, the maximum coil weight for aluminum coils ranges from around 5,000 to 25,000 pounds. However, it is important to note that these figures are approximate and can differ depending on the manufacturer's guidelines and equipment capabilities. Additionally, it is always recommended to consult the manufacturer or supplier for specific coil weight limitations to ensure safe handling and transportation.

- Q: How are aluminum coils protected against scratching and abrasion?

- Aluminum coils are typically protected against scratching and abrasion through various methods, such as applying a protective coating or film. This coating acts as a barrier, shielding the surface of the coils from potential damage during handling, transportation, and processing. Additionally, some manufacturers may use protective packaging materials, such as plastic or cardboard, to further safeguard the coils against scratching and abrasion.

- Q: The box doesn't tell me. I need to know because my gun range won't allow steel or aluminum cartridges

- a magnet can help to determine if it's steel, since brass isn't magnetic. as for aluminum, they'll have aluminum look to them, they never paint them to allow you to identify them, so silvery grey isn't what you're looking for. essentially, as long as the case isn't magnetic and isn't shiny grey, you should be fine. on a side note, I don't really understand why a gun range would forbid steel and aluminum cased ammo, unless they're trying to force the customers into buying the range's ammo instead of less expensive surplus or aluminum cased ammo. PS: Sirbobby, some ranges have a it touches the ground it's ours policy and they do strictly abide by it, if you pick up spent brass, they give you a warning and if you do it again, they throw you out and ban you from the range. they own the property and range and make the rules. I would always read their rules before applying for a membership or even going there.

- Q: Is it possible to join steel coils using arc welding or gas welding techniques?

- <p>Yes, steel coils can be welded together using both arc welding and gas welding methods. Arc welding, specifically processes like Shielded Metal Arc Welding (SMAW) and Gas Metal Arc Welding (GMAW), is commonly used for joining steel due to its strength and versatility. Gas welding, which uses a fuel gas and an oxygen mixture to produce a flame, is also suitable for steel welding, although it may be less common in industrial settings due to the higher heat input and potential for distortion. Proper techniques and equipment are essential to ensure a strong, durable weld and to avoid defects such as cracking or warping.</p>

- Q: Can aluminum coils be used in the manufacturing of electronic devices?

- Yes, aluminum coils can be used in the manufacturing of electronic devices. Aluminum has excellent electrical conductivity and thermal properties, making it suitable for various applications in electronics, such as in transformers, inductors, and heat sinks. Its lightweight nature and corrosion resistance also make it a popular choice for electronic components.

- Q: Is aluminium a safe metal to put in ones mouth without any side effects?

- yes because saliva cannot break down aluminium. Saliva can only break down starch like break using it's enzymes(amylase)

- Q: Are aluminum coils suitable for heat exchangers?

- Yes, aluminum coils are suitable for heat exchangers. Aluminum is a highly efficient and effective material for heat transfer due to its high thermal conductivity. It can quickly transfer heat from one medium to another, making it ideal for heat exchangers where efficient heat transfer is required. Additionally, aluminum coils are lightweight, corrosion-resistant, and have excellent durability, making them a popular choice for various applications, including heat exchangers. The corrosion resistance of aluminum ensures that the coils can withstand harsh environments and prevent the formation of rust or corrosion, prolonging the lifespan of the heat exchanger. Moreover, aluminum coils are easily moldable and can be formed into various shapes, allowing for flexibility in design and construction of heat exchangers. This versatility makes them suitable for a wide range of applications, including HVAC systems, refrigeration units, and automotive cooling systems. In summary, aluminum coils are well-suited for heat exchangers due to their high thermal conductivity, lightweight nature, corrosion resistance, durability, and versatility. These properties make aluminum coils an excellent choice for efficient heat transfer in various industries.

- Q: Can aluminum coils be anodized for enhanced durability?

- Yes, aluminum coils can be anodized for enhanced durability. Anodizing is a process that creates a layer of aluminum oxide on the surface of aluminum, making it more resistant to corrosion, wear, and scratches. This layer also provides added protection against UV rays and harsh environmental conditions. By anodizing aluminum coils, they become more durable and can withstand prolonged use in various industries such as construction, automotive, and electronics. Additionally, anodized aluminum coils can be further treated with additional coatings or finishes to enhance their appearance and offer further protection. Overall, anodizing aluminum coils is a widely used and effective method to enhance their durability and prolong their lifespan.

Send your message to us

High Quality Aluminum Coils - Mill Finished Aluminum Treadplate with Big Five Bar Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords