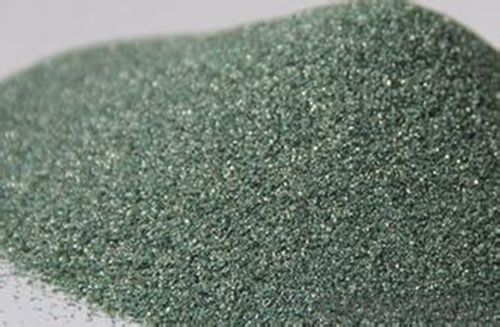

High Purity Green and Black Silicon Carbide - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 1) 25kg woven bag,40 woven bags/jumbo bag. 2) 25kg woven bag,40 woven bags/pallet 3) 25kg paper bag,40 paper bags/pallet 4) 25kg paper bag,40 paper bags/paper box |

| Delivery Detail: | 10DAYS AFTER CONFIRMATION ORDER |

Specifications

F220 High purity SiC

Professional manufacturer

Passed REACH ,ISO-9001:2008

We provide the best quality C in china with high tech testing instrument gurantee the quality.

Grinding Black Silicon Carbide

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw materials. It is used for making bonded and coated abrasive tools, grinding metal and non-metal materials of lower tensile strength, such as gray cast iron yellow bronze,aluminum, stone, leather, rubber, etc.

Chemical Compsition (%)

Grit | Sic | F.C. | Fe2O3 |

F12-F90 | ≥98.50 | <0.20 | ≤0.60 |

F100-F150 | ≥98.00 | <0.30 | ≤0.80 |

F180-F220 | ≥97.00 | <0.30 | ≤1.20 |

F230-F400 | ≥96.00 | <0.40 | ≤1.20 |

F500-F800 | ≥95.00 | <0.40 | ≤1.20 |

F1000-F1200 | ≥93.00 | <0.50 | ≤1.20 |

P12-P90 | ≥98.50 | <0.20 | ≤0.60 |

P100-P150 | ≥98.00 | <0.30 | ≤0.80 |

P180-P220 | ≥97.00 | <0.30 | ≤1.20 |

P230-P500 | ≥96.00 | <0.40 | ≤1.20 |

P600-P1500 | ≥95.00 | <0.40 | ≤1.20 |

P2000-P2500 | ≥93.00 | <0.50 | ≤1.20 |

Physical Index

Grits | Bulk Density | High Density | Grits | Bulk Density | High Density |

F16 ~ F24 | 1.42~1.50 | ≥1.50 | F100 | 1.36~1.45 | ≥1.45 |

F30 ~ F40 | 1.42~1.50 | ≥1.50 | F120 | 1.34~1.43 | ≥1.43 |

F46 ~ F54 | 1.43~1.51 | ≥1.51 | F150 | 1.32~1.41 | ≥1.41 |

F60 ~ F70 | 1.40~1.48 | ≥1.48 | F180 | 1.31~1.40 | ≥1.40 |

F80 | 1.38~1.46 | ≥1.46 | F220 | 1.31~1.40 | ≥1.40 |

F90 | 1.38~1.45 | ≥1.45 |

Size Available

F12-F1200,P12-P2500

0-1mm,1-3mm,6/10, 10/18, ,200mesh,325mesh

Other special spec. could be supplied as required.

- Q: Can anyone tell me the requirements of the refractory masonry??

- Kaolin is mainly composed of kaolinite crowded minerals that is in the shpe of tiny flake which is less than two microns, tube and folding flake. The kaolinite crowded mineral consists of kaolinite, dickite, pearl stone, halloysite, etc. and its ideal chemical formula is AL2O3-2SiO2-2H2O. The main mineral component of it is kaolinite and halloysite.In addition to the kaolinite crowded mineral, kaolin is accompanied by other minerals like montmorillonite, illite, pyrophyllite, quartz and feldspar. The chemical composition of kaolin contains large amounts of AL2O3, SiO2, and a small amount of Fe2O3, TiO2, and traces of K2O, Na2O, CaO and MgO, etc. The white pottery is made of kaolin. At present, the internationally accepted scientific name for kaolin is Kaolin which is derived from the kaolin mountain in the eastern suburb of kaolin village in Jingdezhen.Such special properties of kaolin as its plasticity,cohesiveness, certain dry strength, sinterability and firing whiteness make it the main raw material for ceramic production; properties like whiteness, softness, high dispersibility, and adsorbability allows it to be widely used the paper industry. In addition, the kaolin is also widely used in some industrial sectors such as rubber, plastics, refractories, oil refining as well as agriculture sector and cutting-edge technology for national defense. According to the purpose and requirements, kaolin can be processed and purified and it can be used to manufacture activated clay.

- Q: What kinds of refractory will be used in kiln of sintering ceramics?

- Porcelain has many classes, including acid, alkaline and neutral materials.

- Q: What are the characteristics of thealuminium oxide refractory?

- The substance used in refractories must have the following characteristics and properties: 1, High stability: Anti-oxidation, anti-reduction and thermal decomposition; 2, High melting point of 2800 degree; 3, Low price. The magnesium oxide refractories have all these three characteristics and properties, particularlly in the aspects of melting point and stability .

- Q: what is the original materials of fireproof coating?

- Fire retardant coating is composed of the base materials (that is film forming substance), pigments, ordinary coating additives, fire retardant agent and dispersion medium. In addition to fire retardant agent, other components functions the same as in ordinary coating, but its performance and thickness are specifically required. Some solvent-based fire retardant coating can burn upon encountering fire before construction.In fact,It is the flammable solvent contained in the coating that is burning while substances such as the base materials and fire retardant agent does not burn. Because solvent-based fireproof coating contains organic solvent and these fire-resistant coating, once leaked from the bucket, are likely to cause a fire. Fireproof coating on the substrate can insulate heat only after the solvent contained evaporates compeletly.

- Q: Where is refractory used? Thank you!

- Currently, refractory is widely used as inorganic nonmetallic material of production equipment lining in metallurgy, ceramics and other industries. The current definition of refractory does not only depend on whether the refractoriness is above 1,580℃.

- Q: What's the classification of flameproof glass, the refractory time of fireproofing glass.

- who knows the classification of fireproofing glasses, how long is the fire-resistant time?

- Q: Can anyone tell me what is a high alumina refractory?

- High alumina refractories: High-alumina refractory products have high refractoriness, compressive strength and refractoriness under load, which are used for building the high-temperature parts of various large blast furnaces, such steelmaking furnace, airheater, electric furnace, rotary?kiln and other thermal equipment.

- Q: What are the commonly used admixture for alumina-magnesia refractory? What are the impacts on its performance?

- Sodium silicate, pure calcium aluminate cement, boric acid

- Q: Could you tell me how does fire protection standard of decorative material is divided?

- Divided by plate material: structure material, base layel materials and fabric; Divided by fire protecrtion type: easy to burn, difficult to burn, flame retardant, incombustible material. Material has no fire rating, only the different from the time of combustion limit. Building fire protection. Building fire protection is the fire prevention measures of buildings. In the architectural design, fire protection measures should be taken to prevent fires and reduce fire hazards to life and property. Building fire prevention measures includs prophylaxis before the fire and measures during the fires. The former is mainly to determine the fire resistance rating and fire-proof structure, control fuel quantity and space easy to fire site; The latter mainly for fire partition, setting of evacuation and smoke, fire-fighting equipment, etc. In ancient China, flammable wood are usually taken as a building material, which has accumulated many experiences for the building fire protection .

- Q: What are the requirements for fire?rating of construction suspended ceiling material ?

- According to No. 42 ducument of department of housing construction and Ministry of Public Security: fire?rating of building suspended ceiling material should reach A level. Other civil buildings: Class A fireproofing material MCM should be set in buildings whose height is above 50 meters. National A level fireproof flexible?material is made up of soil, rock flour, sand, cement and other inorganic powder and modifying agent. Product density is 2327kg / m3. Upon examination, the combustion performance of the product meets A level requirements, and the additional classification meets s2, d0, t0 requirements. According to GB 8624-2006 sepcification, combustion performance of the product should reach A2-s2, d0, t0 level. Light, thin: 2-4mm thick / piece, saving space and cement, convenient to transport. : State Class A fireproof flexible?material. Freezing-thaw resistance: up to 100 freezing-thaw experiments (close to 100 years), the surface has no powder, no crack and no peeling. Aging and acid resistance: anti-aging property can reach more than 3500h, that is, it will not degenerate for 50 years. Recyclable: new energy, renewable , no "three wastes" emission

Send your message to us

High Purity Green and Black Silicon Carbide - Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords