High Pressure Dry Scroll Explosion-proof Vacuum Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Oil Free Scroll Vacuum Pumps

1.Structure of Oil Free Scroll Vacuum Pump

single stage rotary vane vacuum pumps combining with many years of experience in vacuum engineering and the latest international vacuum technology developed to meet requirements of both the industry and the environment.They are being used in all areas of vacuum engineering. They are equally suited for both industrial production and research applications. They may be used to generate a rough and medium vacuum or as backing pumps in pump combinations with Roots pumps or high vacuum pumps. The comprehensive range (pumping speeds ranging from 10 to 630 m 3 / h) allows every customer to select the right pump for his particular needs.

2.Main features of Oil Free Scroll Vacuum Pump

• Long life design

• The comprehensive range from 10 to 630 m 3 / h

• Vacuum pump entirely replace the pumps like U3/U4,R5,VC,EU and etc.

• High pumping speed also at low pressures

• Optimum price-to-performance ratio

• Low noise level

• Low vibrations

• Integrated exhaust filter, up to 99.9% efficient

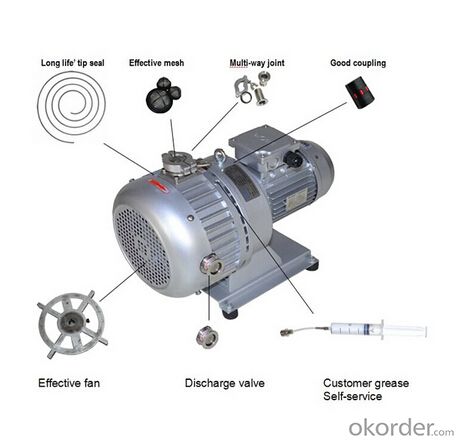

3.Oil Free Scroll Pump Images

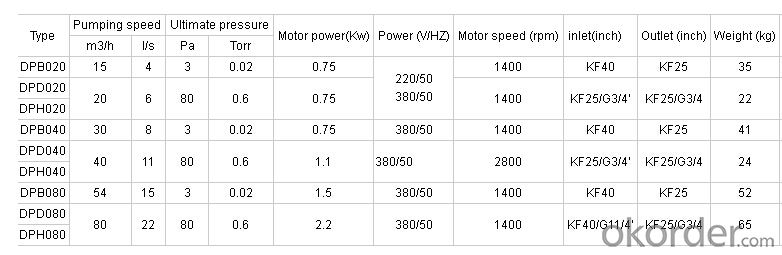

4.Oil Free Scroll Vacuum Pump Specification

5.FAQ

①Application

Food industry , Vacuum packaging, Material drying, Car industry , Furnaces and plants , chemical, Laser technology , Medicinal technology , Metallurgy , Power engineering , Space simulation , Vacuum coating , vacuum loading, electronics, semiconductor, scientific research

- Q: What is a water pump coupling device?

- Advantages of water pump coupling device:1. automatic coupling device, easy installation and maintenance. In the absence of automatic coupling device, fixed installation, such as water pump failure, maintenance personnel need to unscrew screws, lifting pumps for maintenance, or with other small pumps pumping water perfect maintenance,If the water is dirty, it is difficult for people to get down, when the inspection and repair encountered great difficulties. But it is equipped with GAK submersible sewage pumpAfter the automatic coupling device needs lifting, the person can directly lift the water pump without the need to screw the screw into the waterAfter graduation, down the guide rail, you can realize the sealing of water pump and pipeline, so as to make the pump run normally. Small sewage pumps are freeInstallation, large sewage pumps are generally equipped with automatic coupling device, automatic installation, installation and maintenance is very convenient.

- Q: Fire hydrant pump button, under what circumstances do not need to install?

- The installation of hydrant pump buttons depends on the type of water supply:(1) municipal water supply; (in this case, do not have to install)(2) there is a fire pump; (must be installed)

- Q: How about the depreciation of vacuum pumps?

- (five) electronic equipment, for 3 years.The depreciation period of a vacuum pump can be calculated for 5 years. The expected residual rate is generally 5%, or it can be estimated by itself.

- Q: What are the causes of pump shock?

- 3. the water pump set screws loose, adjust the concentric, fastening the foot4. pump into foreign body, open cover overhaul5. the flow is too large or too small, adjust the equipment to control the water output

- Q: What are the functions of a disposable infusion pump?

- This is a very professional question, ha!I only know disposable infusion pumpsAttached: intelligent medical infusion pump and its application

- Q: What is the relationship between the minimum suction vacuum of a pump and the required cavitation?

- Suction is allowed to pump the vacuum from the distance from the inlet, which is part of the field installation.The manufacturer of cavitation allowance is closely related to the design and process of pump. Estimation formula: cavitation allowance =10.33 meters - allow suction of -0.5 meters (safety).

- Q: What are the basic technical parameters of the pump?

- Two, pump head H head is the unit weight of the liquid pump pumping from the inlet of the pump (pump inlet flange) to the outlet of the pump (pump outlet flange) energy value. Effective energy is a Newtonian liquid through the pump unit is obtained. The N m/N=m, the height of liquid column pumping liquid. Habits referred to as meters. Three, the pump speed is n RPM pump unit time revolutions, represented by the symbol n, the unit is r/min. four, the pump NPSH NPSH NPSH is also called net positive suction head, said main parameters of cavitation performance. Cavitation has been used a h power of five, the power of the pump. And the efficiency of the pump is usually refers to the input power, which is the prime mover on the pump shaft power, it is also known as the shaft power, denoted by P;

- Q: What are the parts of a pump? How do you classify it?I just want to know

- The liquid ring pump: pumping air, the working medium is generally at room temperature water gas lift pump: simple structure of submersible sewage pump: a form of basic principle, performance parameters of centrifugal pump, with it the same. Underwater installation, sound, water cooling condition, screw pump: spiral lower invasion water medium variety formThere are too many kinds of pumps, such as submersible pumps for wells, centrifugal feed pumps, sewage pumps, etc. the submersible pumps are wet, oil immersed, etc.The water pump for automobiles is divided into oil lubrication and grease lubrication,

- Q: What are the problems that should be paid attention to when using vacuum pumps?

- (1) check the vacuum pump line and the joint site regularly to see if there is any looseness. Turn the vacuum pump by hand and see if the vacuum pump is flexible.(2) add lubricating oil to the bearing body, observe the oil level at the center line of the oil mark, and the lubricant shall be replaced or supplemented in time.(3) plug screw vacuum pump of the water screw, filling water (or lead paste). (4) turn off the gate valve of the water outlet pipe and the outlet pressure gauge and the vacuum gauge. (5) point motor, and see if motor steering is correct.(6) start the motor. When the vacuum pump is in normal operation, open the outlet pressure gauge and the inlet vacuum pump. As soon as the proper pressure is shown, the gate valve is gradually opened, and the motor load is checked.

- Q: What is the series of pumps? What is the difference between a unipolar and a multilevel? What is the meaning of each "first class"?

- Each impeller is of the first stage. (two impellers share only one level, and exit is only level one)

Send your message to us

High Pressure Dry Scroll Explosion-proof Vacuum Pumps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100000000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords