Plastic Sheets - High Density PVC Foam Sheet, Rigid PVC Foam Board 1220*2440mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

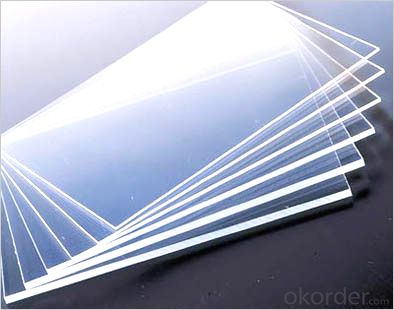

high quality 10mm pvc foam board malaysia is a new particularly lightweight, closed cell substrate board material for printing and mounting jobs.

The distinguishing feature of PVC boards are the bright white,

uniform surfaces. This is an undispensable feature when it comes to digital printing.

PVC foam board is divided into two groups. One is PVC free foam board, and another is celluka foam board.

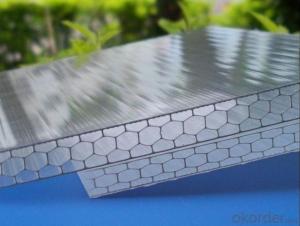

Advantages in building construction

1. Easy to take off from the concrete. Concrete wont be sticky to this kind of board.

2. Adjustable size. The board size is adjustable according to the requirement from the builder.

3. Shiny and Smooth surface.The concrete is with smooth surface after stripped .

4. Steady quality.pvcboard is with very good mechanical strength, It can work well between -20 degree and 100 degree.

5. Easy to install and save labor. It is in light weight and can be processed to any shape and size, save labor.

6. Product attribution is good. wpc board is antisepticise, inflaming retarding and waterproof.

7. Energy saving and environment protect.

8. Lower cost. Turnover can be up to over 30 times, so deeply reduce the cost.

- Q: What are the different grades available for plastic sheets?

- There are various grades available for plastic sheets, including general-purpose grades, high-impact grades, high-temperature grades, food-grade grades, and UV-resistant grades. Each grade is designed to meet specific requirements and applications, ensuring durability, strength, temperature resistance, safety, or specific industry standards.

- Q: Can plastic sheets be used for insulation in vehicles?

- Yes, plastic sheets can be used for insulation in vehicles. They can provide a layer of thermal insulation to help regulate temperature and reduce heat transfer, improving the overall comfort and energy efficiency of the vehicle. Additionally, plastic sheets can also offer sound insulation, reducing noise from outside sources.

- Q: Like the clear plastic used in packaging, and on kids toys and stuff.

- Try hardware stores, home depot, lowe's, that sort of store. Most likely in the paint department. Are you going to use oil with these sheets..... just asking.... LOL

- Q: why do 5 year old boys sleep in plastic sheets?

- What!!!!!!!!! Its probably the plastic sheet which goes under the bottom sheet. This prevents any urine going onto the mattress.

- Q: other than the internet

- All the big stores like Target, Wal Mart, and Kmart usually carry them. If I had the option I would go to a small local store though, it will just help you build a relationship with them.

- Q: Are plastic sheets resistant to fire?

- No, plastic sheets are not inherently resistant to fire.

- Q: i need help finding large plastic sheets like the stuff they use on flimsy 3 ring binders?

- Did you go to the yellow pages and look for plastics? Did you Google it for your area?

- Q: Will plastic sheeting outside window reduce the moisture condensation inside?

- Not okorder

- Q: Can plastic sheets be used for point-of-purchase displays?

- Yes, plastic sheets can be used for point-of-purchase displays. Plastic sheets are a versatile material that can be easily shaped, printed on, and customized to create eye-catching displays for products in retail environments. They offer durability, transparency, and flexibility, making them an ideal choice for showcasing merchandise and attracting customers at the point of purchase.

- Q: What is the minimum temperature that plastic sheets can withstand?

- The minimum temperature that plastic sheets can withstand depends on the specific type and composition of the plastic. However, most common plastics can typically withstand temperatures as low as -40 degrees Celsius (-40 degrees Fahrenheit) before becoming brittle or experiencing structural damage.

Send your message to us

Plastic Sheets - High Density PVC Foam Sheet, Rigid PVC Foam Board 1220*2440mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords