High Alumina Cement Powder for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Aluminate cement is a hydraulic cementitious material prepared by calcining aluminum clinker and limestone as raw materials, with calcium aluminate as main component and alumina content of about 50%.

Aluminate cements are often yellow or brown color, and even gray color The main minerals of aluminate cement are calcium monocalcium phosphate (CaO·Al2O3, abbreviated CA) and other aluminates, and a small amount of dicalcium silicate (2CaO·SiO2). The colors are mostly gray and white.

Quick Details

Place of Origin:China

Application: Refractory,

Shape: Powder

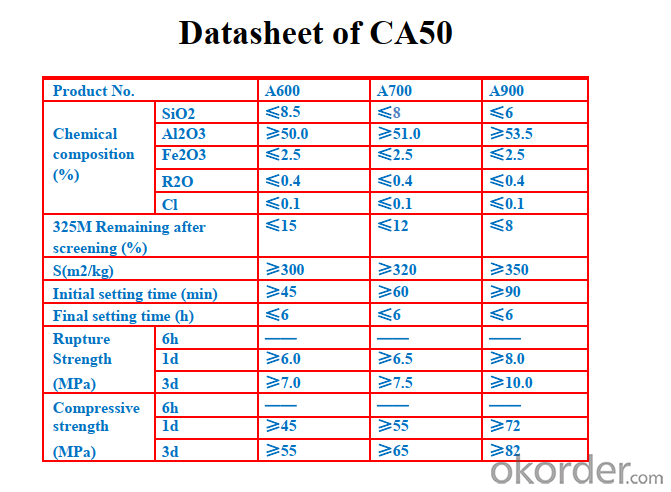

Material: AL2O3,SIO2,FE2O3

Chemical Composition: AL2O3,SIO2,FE2O3

Product name: refractory cement

Payments terms: 1. 100% L/C at sight 2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Advantage: Timely Shipment, High quality, Good performance

Packing: 25kg/bag, 1mt/bag or as customers' requirements

Size: powder

Sample supply: free sample

Color: gray/yellow

MOQ: 25Mt

Supply Ability

Supply Ability:500 Metric Ton/Metric Tons per Month

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

Loading:

- Q: How to understand qualitative and qualitative refractory materials?

- Such as amorphous refractory castable, referred to as bulk loading, cast material, ramming material, refractory clay etc., utensils and other special products. Amorphous refractory material products, refractory heat insulating bricks and experimental and industrial crucible, spraying materials, such as burning bricks, electric melting brick, turn it into required shape and process heat treatment in where it is used.

- Q: What are the physical properties of refractory material?

- The mechanical properties of refractory material include compressive strength, volume density and sclerosing, slag resistance, elastic modulus, thermal shock resistance, oxidation resistance, bibulous rate, fluidity, resilience, bond strength and slump, electrical conductivity, specific heat, heat capacity, the impact strength, linear change, torsional strength, stomatal aperture distribution, resistance to acid, etc. The use performance of refractory material include refractoriness, thermal emissivity, condensation, porosity, coefficient of thermal expansion. Thermal properties of refractory material include thermal conductivity, temperature conductivity, plasticity, the hydration resistance, creep performance. The physical properties of the refractory materials include structure performance, mechanical properties, shear strength, load softening temperature, CO erosion resistance. The structure properties of the refractory materials include porosity, alkali resistance and sintering. The operating performance of refractory material include consistency, tensile strength, the use performance and operating performance, wear resistance, bending strength, thermal properties.

- Q: Which are fire proofing thermal insulation materials?

- Fire proofing thermal insulation materials include: fire proofing heat insulating brick, fire proofing thermal baffle, fire proofing thermal insulation paper, fire proofing thermal insulation felt, fire proofing blocking, fire proofing fiber bulker, castable refractory, etc. In addition, there are also auxiliary products such as fire proofing cement gum, high temperature binder.

- Q: What is the classification standard of fireproofing material levels?

- the following are the criteria: Currently fire materials levels mainly include:class A : incombustible building material,which almost doesn't burn. class A1: non-combustible, without open fire, class A2, non-combustible, it needs to measure the smoke and be qualified. class B1: nonflammable building material: nonflammable materials have good flame resistance function. when it contacts open fire or is under high temperature, it's difficult to burn and be spreading rapidly, and will stop burn after removing the combustion?source. class B1: combustible?building?materials: combustible materials have good flame resistance function. when it contacts open fire or is put in the air at high temperature, it will immediately burst into flames, and easily result in the spreading of fire, such as wooden column, timber roof truss, timber beam, wooden stairs, etc. class B3: inflammability building materials, without any flame resisting effects, easy to burn, and has large danger of fire disaster. In addition, according to different standards, fire-proofing materials' grade partition is different: DIN4102: A1, A2, B1, B2, B3: EN13501-1 A1, A2, B, C, D, E, F

- Q: How to measure the influence of high-temperature performance of the products refractory in the formation of the liquid phase.

- Seeing whether it can affect the usage of the refractory material, and seeing to reduce the impurity, what's the condition of temperature of the liquid phase. Practically, whether it has any difference if you can improve, load under load and creep and reduce the impurity content. In the refractories, producing liquid are the influence of impurities, high temperature resistant strength, compared the use of the refractory material temperature: testing compressive strength after burn. If there are any impact: knowing the main crystal phase of matrix composition and content, improving the content of the main crystalline phase can improve the high temperature performance of refractory materials.

- Q: What refractories can withstand high temperature above 2100 degrees?

- Usually a dryer will not have such a high temperature. I do not know what you would use it for. Refractory cement coupled with quartz sand can work for 4 to 5 hours. So you can try cement coupled with corundum or superfine bauxite for better effect.

- Q: How many kilns using refractories are needed? What are the furnaces respectively?

- Rotary kiln, general alumina bricks, high alumina bricks, corundum - mullite brick and vertical kiln. I am limited. Please forgive me that I can only talk about what I know. There are tunnel kiln, clay brick, etc. which can be used in these kiln and shuttle kiln and so on. Shuttle kiln.

- Q: Introduction to refractory material

- Refractory material refers to inorganic non-metallic materials with refractoriness of no less than 1580℃. Refractoriness refers to the centigrade temperature of refractory cone sample in the case of no load when resisting high temperature without softening. But the refractoriness alone cannot descript the refractory material, thus 1580℃ is not absolute. Now refractory material is defined as material used in high temperature allowed by its chemical properties. Refractory material is widely used in metallurgy, chemical industry, petroleum, machinery manufacturing, silicate and power industrial area, of which the application in metallurgy accounts for the largest part of 50% ~ 60% of total output.

- Q: Are there any differences between insulation and refractory materials ?

- Refractory materials can resist more than 1200 degrees, some of which are not insulation materials, such as firebricks, which can directly contact with heat source, has little insulation effect. Ceramic fiber, high silica, etc. are all refractory materials which can insulate. Insulation materials with poor performance usually is lower than 800 degrees, which have large thermal resistance, and low thermal conductivity, high porosity. Thus they reduce the thermal loss. To put it simply, insulation materials store most of the heat and only let a small part of heat lose through the air, thus the heat has been isolated. Glass fiber, rock wool, flexible material for thermal insulation, etc.

- Q: What are the main materials in concrete fireproofing material?

- fireproofing materials mainly consist of class A incombustible?material and class B1 nonflammable material. Class A incombustible?material: Granite, marble, terrazzo, cement products, concrete products, gypsum board, lime products, clay products, glass, tiles, mosaics, steel, aluminum, copper alloy; class B1 nonflammable material: Ceiling materials, dry wall, fibrous plaster.

Send your message to us

High Alumina Cement Powder for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords