High Alumina Brick for Pottery Kiln DJM26 Insulating Firebrick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | Alumina Block |

| SiO2 Content (%): | 33% | Al2O3 Content (%): | 55% | MgO Content (%): | ≤0.25% |

| CaO Content (%): | ≤0.25% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | ≤0.25% |

| SiC Content (%): | ≤0.25% | Model Number: | DJM26 insulating firebrick | Brand Name: | CNBM |

| Standard: | ASTM &JIS | Density: | 0.8g/cm3 | Compressive strength: | ≥1.8MPa |

| Repture strength: | ≥1.4MPa | Linear Change on Reheating: | 1400c*12h≤0.5% | Thermal shock resistance time: | >20 |

| Heat conductive cofficient: | 600℃ - 0.25w/m.k 800℃ - 0.27w/m.k | Fe content: | ≤0.7% | Standard Size: | 230*114*65/75mm |

| Product name: | CCEWOOL pottery kiln used DJM26 insulating firebrick |

Packaging & Delivery

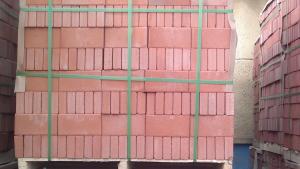

| Packaging Details: | Pallet or cartonCCEFIRE pottery kiln used JM26 refractory insulating firebrick |

| Delivery Detail: | Shipped in 15 days after payment |

pottery kiln used DJM26 insulating firebrick , using high pure mullite as raw material, is made by adding alumina powder according to different type and then sintering in high temperature. JM insulating brick is the new energy saving material for insulation.

- Q: Is there a big difference between two high alumina brick and one high alumina brick?

- The difference between the two kinds of high alumina bricks is great. I perennial in Zhengzhou was responsible for the production and sale of colt refractories

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: What are the high temperature refractory mortars made of?

- Siliceous mud, mineral composition and chemical composition is similar with silica, excellent corrosion resistance, water glass slurry, drying shrinkage, but also can be used for bonding fiber products, sealing furnace wall.

- Q: What are the specifications for bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: The difference between ordinary and diatomite brick refractory brick

- To say the difference, the material is the biggest difference. There are diatomite brick density, compressive strength of small brick kiln belongs to the outer thermal insulation, and heavy refractory brick kilns for multi village in direct contact with the flame, high temperature resistance, good compressive strength, but no insulation. Hope to help you.

- Q: How to distinguish the good or bad of the high aluminum brick?

- The general high alumina bricks used in the steel, steelmaking, hot blast furnace, electric furnace, blast furnace, reverberatory furnace, rotary kiln lining of industrial furnace in China, mainly composed of a bauxite; sillimanite minerals (including kyanite, andalusite, sillimanite etc.); synthetic material, such as alumina synthesis of mullite, corundum, etc.. High aluminum brick has good quality, high refractoriness, long life and other characteristics, is the main use of refractory brick kiln products, commonly used units can not distinguish the quality and grade of high aluminum brick right in the procurement time, caused by the high prices to buy low grade products, thereby reducing the furnace life therefore, Zhengzhou's Sindh yuan refractory material factory in here is simple to introduce how to identify the quality when purchasing brick high alumina brick.Color: in the purchase of high alumina brick, first of all to see the color, high quality aluminum brick surface smooth, yellow color white, four sides smooth, no broken angle, no cracksWeight: the weight of a block of bricks to be called, according to the standard weight level, high aluminum brick weight of 4.5 kg. Two grade high alumina brick weighs 4.2 kg, three high aluminum brick weighs 3.9 kg, the same level, the same parameters can reach this standard can be regarded as high-quality high aluminum bricks, the opposite is not up to the weight that the quality is good, if there is a crack, four angle uneven, off angle phenomenon, then substandard products, some of the above points to help to the purchaser

- Q: What is the apparent porosity of high alumina brick?

- Total porosity is porosity refers to the total volume of sample porosity in the percentage of total volume of samples. Apparent porosity refers to the percentage of the total volume of openings, pores, and total specimens in the sample.

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Two times mullite refers to the content of aluminum is about 70%, in high temperature sintering, the expansion coefficient is large, the thermal expansion rate is high.

- Q: Does the chimney have high acid resistance?

- If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

- Q: What are the categories of bricks?

- Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

Send your message to us

High Alumina Brick for Pottery Kiln DJM26 Insulating Firebrick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords