High Alumina Brick - Firebrick/Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Jiangsu, China (Mainland) | Shape: | Brick | Material: | Mullite |

| SiO2 Content (%): | 0.3-15 | Al2O3 Content (%): | 48%-85% | MgO Content (%): | 0.8-1.2% |

| CaO Content (%): | 0.34% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | CrO Content (%): | 0.1-0.3% |

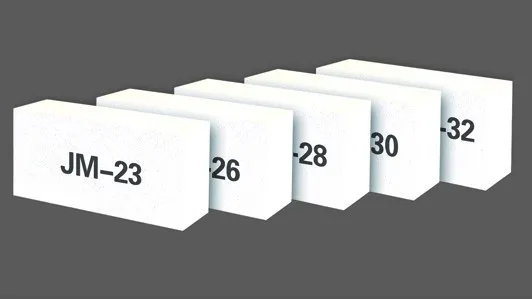

| SiC Content (%): | 1.2-1.4 | Model Number: | JM23 JM26 JM28 JM30 JM32 | Brand Name: | cnbm |

| Name: | insulating Brick | size: | 230*115*65mm | Weight: | 1.19-5kg |

| Color: | white and yellow | Raw material: | mullite & clay | Usage: | Fire resistance place |

| Certificate: | ISO9001 |

Packaging & Delivery

| Packaging Details: | Export wooden pallet or as customers requirements |

| Delivery Detail: | Shipped in 5 days after payment |

refractories insulating bricks mullite bricks

New type quality thermal insulating refractory. It contains alumina 50%-85%, and has mullite (3Al2O3.2SiO2) as major phases and binder phase. Working temperatures are from 1350° C to 1700° C.

Features:

1). High strength as containing high temperature structure

2). Low creep rate at high temperature

3). Low thermal expansion rate

4). Strong resisting chemical erosion performance.

5). Fine resisting thermal shock performance.

3. Property (See below table)

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- From the year 2015 to the year 16 the end of the year, refractories industry presents two kinds of situations: one is a small business, a single product variety and equipment, to meet the demands of both environmental protection and the downstream market, such enterprises are generally in the Qing state inventory;

- Q: What is the price of the latest thermal insulation material?

- Also through online pre understand the products and prices, and now have large-scale manufacturers are generally opened on the cable business. Goods than three, manufacturers on-site inspection, confirm the quality of goods after considering cooperation.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- All the raw materials adding order, mixing time, material and material moisture trapped. 4, the pressure and the volume density of Pei brick and brick Pei size etc..

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- 1. The shell of the furnace is welded by section steel and steel plate. 2, the furnace cover support adopts steel and guide rail combination mobile type. 3. The heating element is made of high resistance alloy 0Cr25Al5 produced by Beijing Shougang Group and arranged on the furnace side. 4, because the bottom bearing adopts high aluminum bricks, the circle center of the furnace set small, inside and outside heating. 5 、 furnace cover adopts hydraulic lifting, motor control, automatic walking. 6 、 temperature control system adopts PID SCR control, high accuracy.

- Q: How are the high alumina bricks fired?

- According to the quality requirements of different grades of high alumina brick, choose different grades of bauxite raw materials, it is conducive to rational use, fine materials, fine distribution, as far as possible not to use mixed grade severe raw materials. The quality of the clinker depends on the calcination temperature, calcination temperature, sintering temperature should be generally reached or slightly higher than that of alumina clinker sintering, to ensure the full and possible high volume density, and the two secondary Mullitization and sintering shrinkage effect in calcination process. Lightweight high alumina brick, also known as high aluminum insulation brick (high-aluminium heat insulating brick). A lightweight refractory consisting of mullite and glass phases or corundum in excess of 48%. The volume density is 0.4 ~ 1.35g/cm3. The porosity is 66% ~ 73%, and the compressive strength is 1 ~ 8MPa. Better thermal shock resistance.

- Q: What are the characteristics of high alumina bricks?

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized high-temperature kilns and other energy consuming industries, such as chemical industry, electric power industry, etc.

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Fire resistance is an important performance index of refractory materials, but it does not represent the highest temperature in actual use of refractory materials. In actual use, refractories also bear certain pressure, therefore, must consider the high strength at high temperature refractory material, which is in high temperature under certain pressure without deformation, such as the NZ-40 refractory refractory degree up to 1730 DEG C, but the maximum temperature is only 1350 degrees celsius.

- Q: What is the difference between fireclay bricks and high alumina refractory bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined. High thermal stability, fire resistance above 1770. Slag resistance is good, used for masonry steel smelting furnace, glass furnace, cement rotary furnace lining.

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Brick - Firebrick/Insulating Brick

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords