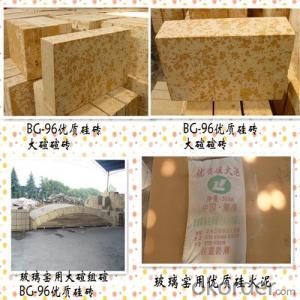

Silica Insulation Brick - Heavy Density Refractory Silica Bricks SiO2 95%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Our Heavy Desity Refractory Silica Bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

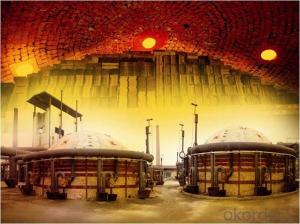

Application

Our Silica bricks are commonly applied in coke oven, hot blast stoves, glass furnace etc.

Features

High refractoriness under load

High mechanical strength

Excellent thermal shock resistance

Corrosion resistance.

YL Silica bricks are made from high quality quartz tail sand, lime and minaralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Technical Data

| Item | arch top and wall brick | lattice brick | ||

| SiO2 ≥ | 95 | 96 | 95 | 96 |

| Fe2O3≤ | 1.0 | |||

| refractoriness≥ º C | 1710 | |||

| True Density g/cm3 ≤ | 2.35 | |||

| Refractoriness under load 0.2MPa, º C≥ | 1650 | 1660 | 1650 | 1660 |

| Apparent porosity(%)AP≤ | 22 | 22 | 23 | 23 |

| Creep(0.2MPa*1550º C*50h) % ≤ | 0.8 | |||

| Thermal Expasion(1000º C) % ≤ | 1.2 | |||

| Cold crushing strength(Mpa) CCS≥ | 35 | 40 | 30 | 35 |

Photos for Applications

- Q: The hot blast stove when the temperature did not rise against the brick interface decreased

- Different insulation methods can be adopted according to the length of the stop time and the location and equipment of the overhaul. Gold, refractory material factory specializing in the production of various specifications of brick

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: Why will expand when heated brick

- Because the production of raw materials are silica brick, brick with SiO2 content of not less than 95% of silica as raw materials, adding mineralizer and binder, through mixing, molding, drying, sintering and other processes in the system

- Q: The specific content is what gb/t2608-2012 brick

- The provisions of the brick classification, technical requirements, test methods,

- Q: Semisilica brick interpretation

- High temperature volume stability. Volume change is small.

- Q: Why is the new trend of the high thermal conductivity of silica brick

- The high thermal conductivity of silica brick all inherits the advantages of traditional coke oven silica brick, on the basis of further highlight the characteristics of high thermal conductivity.

- Q: Can iron oxide be used as refractory material?

- Iron oxide can not be used as refractory material, but it can be used as refractory additive. Iron oxide can be used as pigment

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Brick, high thermal conductivity has been greatly improved in terms of morphology, crystal structure, physicochemical index. The structure and morphology of high thermal conductivity of silica brick,Structure and morphology of high thermal conductivity and the traditional brick brick magnified 20 times were compared, high thermal conductivity silica pore size distribution is more uniform and finer.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.

- Q: The chemical composition of silica brick and its physicochemical index?

- The physicochemical index of silica brick:Turn left to |

Send your message to us

Silica Insulation Brick - Heavy Density Refractory Silica Bricks SiO2 95%

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords