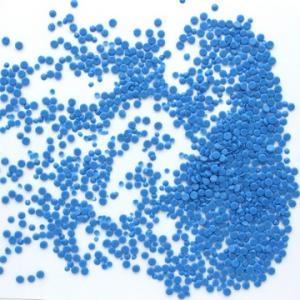

HDPE Resins Raw Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Detailed Product Description

1 Lm, injection, pipe etc grade. 2 Used for shopping bags, plastic wrap, water pipe, gas pipe and so on

HDPE Raw Material,HDPE virgin granules

HDPE resins are produced with low pressure gas phase process. The products are primarily used for extrusion application such as flat Yarn, coarse monofilament, film & sheets and injection molding such as pallets, crates, bottle caps and industrial containers.

Main applications

Injection molding,Casting,Fine monofilament,Injection molding for crate,Flat yarn,Coarse monofilament,Film & Sheet extrusion.

|

Density |

0.95 g/cm3 |

0.949 g/cm3 |

|

Melt flowing speed |

0.07 g/10min |

0.07 g/10min |

|

Yield tensile strength |

24 MPa |

24.1 MPa |

|

Fracture tensile strength |

35 MPa |

35.2 MPa |

|

Elongation at break |

630% |

630% |

|

Flexural modulus

|

1010 MPa |

1010 MPa |

- Q: Plastic raw materials packaging is generally divided into several categories?

- Plastic raw materials are usually packaged as:Barrel packaging: such as: plastic drum with polyurethane raw materials; composite board barrel with some pellets.Bag packing: plastic bag, compound woven bag and composite paper bag (the outer layer of composite bag is paper or woven bag, and the inner layer of contact plastic is plastic or composite aluminium foil).

- Q: What is the ash content of PP plastic raw materials?

- PP if a few raw materials mixed with ash, and the color of raw material and color, it is PP powder, the water can not be dissolved. Try, if it is more, and the color is white, it is talcum powder or toner, water or dissolved or muddy water

- Q: PE plastic bellows raw material formula (PE and PP ratio, as well as other filling)?

- PP and PE plastic corrugated pipe in the role of the following two: 1, PP material can reduce the production of pipe, HDPE than PP pipe grade market sales price higher, the production of HDPE pipeline adding appropriate amount of PP, for the reduction of raw materials

- Q: What is plastic material E-PET?

- PEI is generally broken piece of edible oil bottle, coke bottles, water bottles and other beverage bottles. Professionally speaking, PET is polyethylene terephthalate, and E-PET refers to high transparency, smooth surface, large bottle thickness, high temperature resistance at 120 degrees Celsius or more. Simply put, it's a PET bottle of good quality. Our jargon is a mineral water bottle.

- Q: What are the specific differences between plastics and plastics?

- General characteristics of plastic raw materials (LC plastic raw materials wholesale, high temperature resistant plastic materials, PPS, LCP, PET, PA, PES plastic raw material suppliers):1) the plastic material is heated and compressed, and the coefficient of linear expansion is much larger than that of metal;2) the stiffness of a general plastic material is one order lower than that of the metal;3) the mechanical properties of plastic raw materials will decrease obviously when heated for a long time;4) the general plastic material is temporarily subjected to stress at normal temperature and below its yield strength, and permanent deformation occurs;5) plastic raw materials wholesale, sensitive to notch damage;6) the mechanical properties of plastic raw materials are usually much lower than those of metals, but some composite materials have higher specific strength and specific modulus than metals. If the products are properly designed, they will be more effective;7) the mechanical properties of reinforced plastic raw materials are various;8) some plastic materials absorb moisture and cause changes in size and properties;9) some plastics are flammable.

- Q: Does anyone know what kind of plastic material PP-M40 is?

- Compared with the ordinary PP, the filling PP has the advantages of less shrinkage, higher rigidity and good heat resistance, and is suitable for being used as an electric cooker, an inner ring, an automobile, a motorcycle fitting, etc..

- Q: PVC what is the difference between raw and recycled raw materials?

- Raw raw materials, such as rubber oil from rubber trees, are extracted from recycled products and recycled materials are recycled materials.

- Q: What does plastic material include?

- Method for identifying toxic plastic bags. Water detection method: put a plastic bag into the water, non-toxic can be surfaced, and poisonous won't rise; hand touch detection method: white or colorless transparent is non-toxic, the hand has a sense of lubrication, the surface like wax; color: color detection method of toxic haze or yellow, red and black. Feel sticky; jitter method: take a plastic bag shaking, the sound crisp sound stuffy astringent toxic and non-toxic.

- Q: What does MFI mean in PC material?

- MFI- melt flow index, also known as the melt flow rate (MFR), it was determined at a given shear stress (with applied load) and temperature, melt flow properties of materials (measured by g/10min).

- Q: What is the difference between plastic particles and raw materials?

- Plastic particles: roughly divided into 200 kinds, subdivided, thousands of kinds. There are dozens of common, general plastics, engineering plastics, special plasticsGeneral Plastics: polypropylene, polyethylene, PVC, polystyrene, polyester, polyurethane and so onEngineering Plastics: nylon, PTFE, POM, poly carbon, silicone and so on

In the past years, We have get more and more experiences in sales market and new items developments, Which shall be the great advantages for us to get more achievements in the international market. In the mean time ,our company has been awarded high reputation by the customers.

We will make"quality first,prestige supreme"management policy for our purpose, win your support by reliable product quality,best survice and well-deserved reputation,and provide you with the best quality of the products and professional service in time.

.

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2001 |

| Annual Output Value | |

| Main Markets | North America, South America, Eastern Europe, Southeast Asia, Africa, Oceania, Mid East, Eastern Asia, Western Europe, Central America, Northern Europe, Southern Europe, South Asia, Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Resins Raw Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords