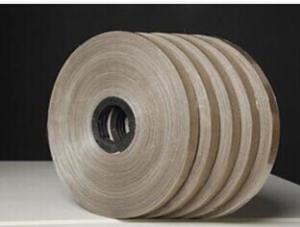

Raw Materials for Refractory Fiber Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Ceramic Fiber Rope

Good Thermal Insulation

Density:500 kg/m3

round ,square braided or twisted

Customized prorduction is ok

LUYANGWOOL Ceramic fiber rope is produced by processing refractory ceramic fiber. Various textiles can be produced by ceramic fiber. LUYANG ceramic fiber ropes are woven or braided from yarn consisting of refractory ceramic fiber with approx 20% organic fibre. Alloy wire inserts are available for obtaining maximum strength ar elevated temperatures. Glas filament inserts are used in applications where electrical resistance is required. LUYANGWOOL ceramic fiber rope can be used up to 1260C.

Application

Gasket and wrapping material.

Cable and wire insulation.

Welding curtains and blankets.

Furnace curtains and heat zone separators

Expansion joint

Fuel line insulation

Welding blankets

High temperature seals and packing in furnace and heaters cord

thermal insulation pipe wrap

furnace door seals jointings.

Standard Specification

Sevice temperature: 450-1000C

Production type: round braided,square braided,twisted

Type: fiberglass reinforced and stainless steel reinforced

Density: 500 kg/m3

Size:

50000/10000x25/50mm ( round braided)

10000x(50x50)mm (square braided)

50000~20000x6~50mm( twisted rope)

Moisture content:≤ 2%

Organic content:≤ 15 %

Description GF-R-Rope SS-R-Rope GF-T-Rope SS-R-Rope

Density (kg/m3) 500 500 500 500

Classification Temperature ( 0C ) 1260

Maximum Operating Temperature ( 0C ) 500-600 1000 500-600 1000

Water Content ( % ) ≤1

Organic matter content (%) ≤15

Reinforced material Glass fiber Stainless steel Glass fiber Stainless steel

- Q: which kind of material is chosen for fireproofing window?

- (1) window frame uses steel frame or wooden frame with certain strength that can safeguard the integrity and stability of the components. (2) steel frame and mound layer can choose galvanized?steel?sheet or stainless steel plate. Its selection criteria conform to the article 5.1 in GB12955 Steel Fireproof Door General Technical Condition. (3) the selection criteria of wooden frame and mound layer should conform to the article 5.1 in GB12955 Wooden Fireproof Door General Technical Condition. (4) the inside filler material of steel, wood frame should use incombustible material. (5) fire-resistant glass can choose test approved products without affecting the fire resistance of fireproofing windows . Light transmittance of glass should not be less than 75% of same layers commom sheet glass. (6) the sealing material between the frame and the fire-resistant glass should use flame retardant materials, it can play a role of fireproofing and smoke insulation in the fire.

- Q: How to divide the fire rating standards of insulation materials?

- 1. According to the GB8624-97 national standard, building materials can be divided into following levels in terms of combustion performance. A-level: Non-combustible building materials: Materials almost don't burn. B1-level: Fire-retardant building materials: Fire-retardant materials are good at resisting flame. It is difficult for them to burst into fire when coming across open fire in the air or at high temperature. It will not quickly get wilder and when the fire source removes, it will be extinguished immediately. B2-level: Combustible building materials: Combustible building materials can play a certain role in preventing combustion. It will immediately burst into flames when coming across open fire or at high temperature, and will lead to fire spreading, such as wooden pillars, roof frames and beams as well as stairs. B3-level: Inflammable building materials: Inflammable building materials are highly flammable with no flame retardant ability. The fire risk is high. 2.The exterior wall thermal insulation materials can be classified according to fire rating. 1. Insulation materials with A-level combustion performance: rock wool, glass wool, foam glass, ceramic foam, foam cement, close-celled perlite, etc. 2. The insulation materials with B1-level combustion performance: specially-treated extruded polystyrene boards(XPS)/ specially-treated Polyurethane(PU), Phenolics, Polystyrene rubber powdery particles,etc. 3. Insulation materials with B2-level combustion performance: Expanded polystyrene sheets(EPS), Extruded polystyrene board(XPS), Polyurethane(PU), Polyethylene(PE), etc.

- Q: what's the classification of fireproof materials?

- Fireproof materials are used in construction, in various forms and it has played an absolute role in modern fireproofing, common fireproofing materials include fireproof?panel, fire door, fireproofing glass, fire?retardant?coating, fireproof bag,etc Or the material itself has a high temperature resistance, heat-resistant, flame-retardant properties. Most of them are used for the construction industry.

- Q: What material is used to make furnace pipe of refractory bricks?

- Furnace pipe of refractory brick is an indispensable part of casting cupola. Furnace pipe is divided into upper and lower part. Radial direction and axial breathing. The upper furnace pipe adopts double layer steel structure and countercurrent air supply mode. The lower furnace pipe is made by processing integrated heat resistant steel in flange, fin and inner wall in wearing parts. The operation life is over 3000h. There is radiating rib of heating air on the edge of furnace pipe liner by using the heat of casting cupola to heat air in cupola. Hot air temperature is about 180-250℃, which contributes to improve trhe thermal efficiency of production equipment, decrease production cost and improve economic benefit of enterprises.

- Q: How is the fire endurance of the fireproof paint?

- fire endurance of fireproof paint is from 1 to 4 hours. Mechanism: Fireproof paint itself is flame-retardant or non-combustible, protecting the substrate from direct contact with the air,delaying the time for catching fire and reducing the burning speed. fireproof paint decomposes with heat and releases non-combustible inert gas, thining out the flammable gas produced by the protected object, making it difficult to burn or slow down the burning. expansive fireproof paint expands under heat and forms a layer of carbon foam insulation to cover the protected object, delay the heat transfer in the substrate , prevent burning and possible losing of fireproof abilitiy because rising temperature.

- Q: What are the raw materials of refractory?

- Refractory is mainly resistant to high temperature and fire. Sic refractories are widely used in refractory. I hope my answer will be helpful to you.

- Q: What is refractory aggregate?

- It includes two categories: coarse aggregate and fine aggregate.

- Q: How many refractories are there for boiler above 1200 ℃?

- In addition to refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and the like. Refractories often used are azs brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nitride, silicide, sulfide, boride, carbide and other nonoxide refractory materials, calcium oxide, chromium hemitrioxide, aluminium oxide, beryllia and other refractories. Thermal insulation refractory materials often used are diatomite product, asbestos product, insulation?board,etc. Unshaped refractories often used are repairing?mass, ramming?mass, castable refractory, plastic refractory, refractory mortar, refractory gunning mix, sling refractory, refractory coating, lightweight refractory?castables, stemming, etc.

- Q: Urgent question: could you tell me that the export of refractory materials to Vietnam is to be packed in wooden cases and smoked?

- If the outer packing is made of solid wood, it must be fumigated! If it is not solid wood, you can do without!

- Q: Who knows how many poured refactory material are there?

- Casting refractory material, refractory material used often are AZS brick, corundum brick, direct bonding magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide brick, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, aluminum oxide, magnesium oxide, beryllium oxide and other refractory materials.

Send your message to us

Raw Materials for Refractory Fiber Rope

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords