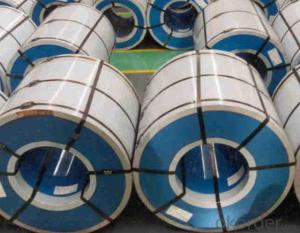

gTop Brand Hexing HDGI Prepainted Steel Coil for Greenboard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,GB,JIS,SGS | Grade: | prepainted steel coil | Thickness: | 0.17-0.5mm |

| Place of Origin: | Anhui China (Mainland) | Brand Name: | CNBM | Model Number: | prepainted steel coil-01 |

| Type: | Steel Coil | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | whiteboard/green board/Projection board | Special Use: | Wear Resistant Steel | Width: | 835-1275mm |

| Length: | As order | Color: | According to RAL Color Systerm or As Per Buyer's Color Sample | Grid line steel: | Produced |

| Cutting line machine: | Yes | Coil weight: | 2-3Ton | OEM: | Yes |

| Flim: | Yes | Apply Kinds: | white board,green board, projection board | Main Color: | White/Green/Black |

| Prepainted steel coil: | Used in Writingboard and Electrical appliance,Hot Dip Prepainted Galvanized Steel Coil |

Packaging & Delivery

| Packaging Detail: | Stardard Seaworthy Package for prepainted steel coil order |

| Delivery Detail: | 15Days after receive payment for prepainted steel coil order |

Specifications

1. Thickness:0.17~0.5mm

2. Width:835~1275mm

3. Top:10~25mu,Bottom:5~7mu

4. Zinc:80~275g

5. Prepainted steel coil

Hexing Prepainted Steel Coil

OUR SPECIFICATION

Manufacturer | Thickness | Width | Inner diameter of coil |

cnbm | 0.17-0.5mm | 835-1275mm | 508mmm |

Certificate | ISO9001 ISO14001 BV | ||

Technique | Hot zinc-coated steel sheet/coil | ||

Coated Mass

Base plate | Available Coated Mass(g/m^2) |

Galvanized Steel | 60,80, 100, 120, 160, 180mm |

Available Painting

Category of painting | Item | Code |

Polyester | PE | |

High-durability polyester | HDP | |

Silicon modified polyesters | SMP | |

Polyvinylidene fluoride | PVDF | |

| Acrylic acid | HPAA |

APPLICATION OF OUR PREPAINTED STEEL

Writing board | Blackboard, White board,Chalkboard, Hidden cell blackboard,Marker Board, Projection board. |

Our Production Line

Our production line is automatic controled by computer to finish products production, by controled the steel speed, temperature,Tension and a series of data to make the production exactly and going well. We also have professional team to maintain our production line regularly. Professional production line and more than 10years in this field, we are more professional!

- Q: Are steel sheets suitable for construction scaffolding?

- Yes, steel sheets are suitable for construction scaffolding. They are strong, durable, and can withstand heavy loads, making them an ideal choice for supporting workers and materials at various heights during construction activities.

- Q: How is the quality of steel sheets determined?

- Several factors and tests determine the quality of steel sheets. The chemical composition of the steel is a primary factor, including the presence and percentage of elements such as carbon, manganese, silicon, and alloying elements like chromium, nickel, and molybdenum. The specific composition impacts the steel's strength, durability, and resistance to corrosion. The mechanical properties of the steel are also important, assessed through tests like tensile strength, yield strength, elongation, hardness, and impact resistance. These tests determine the steel's ability to withstand forces and deformation without failure. Surface quality plays a crucial role as well. The surface must be defect-free, without cracks, scratches, pits, or any irregularities that could affect performance or appearance. Thickness and uniformity are crucial factors too. Thickness is measured using methods like ultrasonic gauges or micrometers to ensure compliance with specifications. Deviations from the required thickness can impact structural integrity and performance. Weldability, formability, and machinability are also tested, determining suitability for specific applications. These tests evaluate the steel's behavior during fabrication processes like welding, bending, or machining. Overall, the quality of steel sheets is determined through a comprehensive evaluation of their chemical composition, mechanical properties, surface quality, thickness, and other performance characteristics. These assessments ensure compliance with standards and suitability for intended applications.

- Q: Can steel sheets be used for toolboxes?

- Yes, steel sheets can be used for toolboxes. Steel is a common material used for toolboxes due to its strength, durability, and resistance to damage. It provides a sturdy and secure storage solution for tools and equipment.

- Q: How do steel sheets handle static electricity?

- Steel sheets possess excellent electrical conductivity, including the conduction of static electricity. This is due to their high electrical conductivity, allowing them to swiftly eliminate any static charge that accumulates on their surfaces. The effectiveness in handling static electricity is mainly attributed to the presence of unbound electrons within the atomic structure of the steel. When a static charge is applied to a steel sheet, these unbound electrons promptly relocate themselves, nullifying the charge and preventing the accumulation or release of static electricity. Furthermore, steel sheets are frequently coated with a thin protective layer, such as zinc or paint, which further enhances their capacity to dissipate static charges. In general, steel sheets are renowned for their dependable performance in managing static electricity and are commonly utilized in various industrial applications where electrostatic discharge may pose risks to safety or cause damage.

- Q: What is the process of galvalume coating on steel sheets?

- The process of galvalume coating on steel sheets involves a continuous hot-dip process. First, the steel sheets are cleaned and then immersed in a bath of molten zinc-aluminum alloy, which typically consists of 55% aluminum, 43.5% zinc, and 1.5% silicon. The steel sheets are carefully passed through the molten bath, ensuring that both sides are evenly coated. As the sheets are withdrawn from the bath, excess alloy is removed by air knives, leaving a thin layer of the galvalume coating on the steel surface. This coating provides excellent corrosion resistance and durability to the steel sheets.

- Q: Can steel sheets be welded together?

- Yes, steel sheets can be welded together. Welding is a common method used to join steel sheets by melting and fusing the edges together, creating a strong and durable bond.

- Q: Are the steel sheets resistant to impact or bending?

- In general, steel sheets display resistance to both impact and bending. Steel possesses exceptional strength and durability, rendering it less susceptible to external forces like impacts or bending. This is attributed to the material's capacity to absorb and disperse applied energy, leading to minimal deformation or harm. Nevertheless, the extent of resistance to impact and bending may fluctuate based on factors such as sheet thickness, steel type, and any supplementary treatments or coatings that have been applied.

- Q: What are the different forms of steel sheets (flat, perforated, expanded, etc.)?

- Steel sheets are available in various forms to suit different applications and requirements. Some of the different forms of steel sheets include: 1. Flat Steel Sheets: These sheets have a smooth and flat surface and are commonly used in construction, fabrication, and manufacturing industries. They are versatile and can be easily cut, shaped, and formed into various products. 2. Perforated Steel Sheets: These sheets feature small holes or perforations that are evenly spaced. They are commonly used for filtration, ventilation, and decorative purposes. Perforated steel sheets provide excellent airflow and visibility while maintaining structural integrity. 3. Expanded Steel Sheets: These sheets are created by cutting and stretching a flat sheet of steel, resulting in a mesh-like pattern. Expanded steel sheets are lightweight, strong, and provide excellent ventilation and drainage. They are commonly used in walkways, gratings, fencing, and security applications. 4. Galvanized Steel Sheets: These sheets are coated with a layer of zinc, which provides excellent corrosion resistance. Galvanized steel sheets are commonly used in outdoor applications where exposure to moisture and harsh weather conditions is a concern. 5. Stainless Steel Sheets: These sheets are made from an alloy of steel and chromium, which provides excellent corrosion resistance and high tensile strength. Stainless steel sheets are commonly used in the food industry, transportation, medical equipment, and architectural applications. 6. Cold Rolled Steel Sheets: These sheets are produced by rolling steel at room temperature, resulting in a smooth and even surface. Cold-rolled steel sheets have improved surface finish, dimensional accuracy, and strength. They are commonly used in automotive, appliances, and furniture industries. 7. Hot Rolled Steel Sheets: These sheets are produced by heating steel above its recrystallization temperature and then rolling it. Hot-rolled steel sheets have a rougher surface and are more malleable compared to cold-rolled sheets. They are commonly used in structural components, construction, and general fabrication. These are just a few examples of the different forms of steel sheets available. Each type of steel sheet has its own unique properties and advantages, making them suitable for various applications and industries.

- Q: What are the common thicknesses for hot-rolled steel sheets?

- The common thicknesses for hot-rolled steel sheets range from 1.6mm to 20mm, with some variations depending on specific industry requirements and applications.

- Q: How do steel sheets compare to wood sheets?

- Steel sheets and wood sheets differ significantly in terms of strength, durability, and usage. To begin with, steel sheets are renowned for their remarkable strength and durability. They can endure heavy loads, extreme weather conditions, and possess high resistance to warping, rotting, and insect damage. Conversely, wood sheets are less sturdy and may succumb to moisture, termites, and decay if not adequately treated or maintained. Regarding versatility, steel sheets offer a wide array of applications. Their high tensile strength and structural stability make them commonly utilized in the construction, automotive, and manufacturing industries. Conversely, wood sheets are commonly employed in interior design, furniture production, and smaller-scale construction projects due to their natural aesthetic appeal and ease of manipulation. Furthermore, steel sheets are fire-resistant, making them a safer option compared to wood sheets, which are combustible and can contribute to the spread of fire. Steel sheets also boast a longer lifespan, necessitating less maintenance and replacement compared to wood sheets, which may require regular refinishing, sealing, or replacement due to wear and tear. Nevertheless, wood sheets possess their own advantages. They are generally more cost-effective than steel sheets, making them a popular choice for projects with budget constraints. Additionally, wood sheets have superior insulation properties, providing natural warmth and soundproofing qualities. Ultimately, the selection between steel sheets and wood sheets hinges on the specific project requirements, encompassing factors such as budget, desired aesthetics, structural needs, and environmental considerations.

Send your message to us

gTop Brand Hexing HDGI Prepainted Steel Coil for Greenboard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords