Grinding Media Ball with High Performance & Competitive Price Used for Metal Mine/Cement Plant/Water Coal Slurry/Power Station/C

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Grinding Media Ball with High Performance & Competitive Price Used for Metal Mine/Cement Plant/Water Coal Slurry/Power Station/Chemical Industry

1. Specifications for Grinding Media Ball with High Performance & Competitive Price

Diameter: 15mm-150mm

Hardness: 55HRC-65HRC

Features: a) Even Hardness b)No Deformation c) Low breaking d) No Mal-roundness F)Grinding resistant G) Low wear rate

Applied Fields: a) Metal Mines b) Cement plants c) Water coal slurry d) Power stations e) Chemical industry

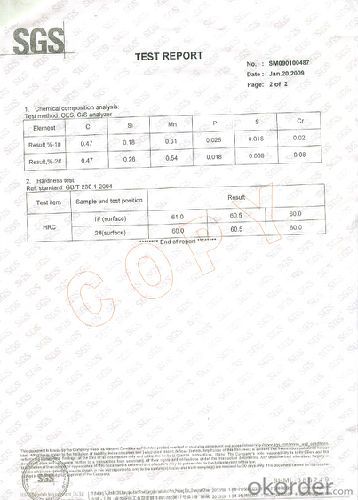

Certification: ISO9001:2008, SGS, etc

2. Classification for Grinding Media Ball with High Performance & Competitive Price

Forged Grinding Ball

Chemical Composition and Specifications of Forged Steel Grinding Ball:

Name | C | Mn | Si | Cr | S | P | ||

60Mn | 0.57-0.65 | 0.70-1.0 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | ||

65Mn | 0.60-0.70 | 0.90-1.2 | 0.17-0.37 | 0.25max | 0.035max | 0.035max | ||

75MnCr | 0.70-0.85 | 0.70-0.85 | 0.17-0.37 | 0.40-0.60 | 0.030max | 0.030max | ||

| | ||||||||

Nominal diameter | Diameteical Tolerance | Weight of single ball in average | Surface hardness | Impact toughness | ||||

(mm) | (mm) | (g) | (HRC) | (j/cm2 ) | ||||

Φ20 | +2 -1 | 32 |

55-65 |

≥12 | ||||

Φ25 | 64 | |||||||

Φ30 | 110 | |||||||

Φ40 | 263 | |||||||

Φ50 | 513 | |||||||

Φ60 | +3 -2 | 888 | ||||||

Φ70 | 1410 | |||||||

Φ80 | 2104 | |||||||

Φ90 | 2996 | |||||||

Φ100 | 4110 | |||||||

Φ110 | +4 -2 | 5457 | 50-60 | |||||

Φ120 | 7102 | |||||||

Φ130 | 9030 | |||||||

Φ140 | +4 -3 | 11278 | ||||||

Φ150 | 13871 | |||||||

Casting Grinding Balls:

Chemical Composition of Casting Grinding Ball:

Item | Chemical Composition(%) | ||||||||

C | Si | Mn | Cr | P | S | Mo | Cu | Ni | |

| | 2.0-3.0 | ≤0.10 | 0.5-1.5 | 10-14 | ≤0.10 | ≤0.10 | 1.0Max | 2Max | 0-1.5 |

High chrome cast grinding balls | 2.0-3.0 | ≤0.10 | 0.5-1.5 | 14-17 | ≤0.10 | ≤0.10 | 3.0Max | 1 Max | 0-1.5 |

2.0-2.8 | ≤0.10 | 0.5-1.5 | 18-22 | ≤0.10 | ≤0.08 | 2.5 Max | 1 Max | 0-1.5 | |

2.0-2.8 | ≤0.10 | 0.5-1.5 | 22-28 | ≤0.10 | ≤0.08 | 3 .0Max | 2 Max | 0-1.5 | |

Middle Chrome Cast Grinding Balls | 2.1-3.2 | 0.5-2.2 | 0.5-1.5 | 6~10 | ≤0.10 | ≤0.10 | 0-1.0 | 0-0.8 | 0-1.5 |

Low Chrome Cast Grinding Balls | 2.2-3.6 | ≤1.2 | 0.5-1.5 | 1.0-3.0 | ≤0.10 | ≤0.10 | ≤0.10 | 0-0.8 | -- |

3. Packing for Grinding Media Ball with High Performance & Competitive Price

4. Testing for Grinding Media Ball with High Performance & Competitive Price

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angleEspecially deep hole, and customers to discuss, generally take 0.3-1 degrees is enough

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- Annealing is needed to eliminate stress and refine grain

- Q: I often see Waixiejiagong drawings, casting, how to distinguish the latheman.

- Casting rough drawings generally no processing symbols, processing drawings indispensable is processing symbols!

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- The finish of reaming depends on the material and the sharpness of the reamer, as well as the speed and speed of the top and bottom. Marine machine tool

- Q: How to distinguish the forging parts and casting parts accurately

- To distinguish from the use of materialsForging materials are mainly made of carbon steel and alloy steel of various components, followed by aluminum, magnesium, titanium, copper and their alloys. The original state of the material is rod, ingot, metal powder and liquid metal. The materials needed for casting are mostly metal, wood, fuel, molding materials and so on. In contrast, the forging parts rarely produce dust, harmful gas and noise, etc., and play a more obvious role in environmental protection. Of course, because of this, the price of forged parts on the market is higher than that of castings.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: Where is the precision casting factory?

- Shandong, DongyingThe birthplace of precision casting

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

- Q: How can the casting be free of trachoma?

- Measures for the prevention of trachoma in castings:1, sand compaction to high, paint two times;

1. Manufacturer Overview

| Location | Zhangqiu, China |

| Year Established | 1995 |

| Annual Output Value | 150,000M.T. |

| Main Markets | 40%,South America; 30%,South Africa; 15%,Southeast Asia; 5%, Europe Area; 5%, North America; 5%, Other Areas |

| Company Certifications | ISO9001:2008;SGS Test Report |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao;Tianjin |

| Export Percentage | |

| No.of Employees in Trade Department | 25 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 68,000m2 |

| No. of Production Lines | 15 |

| Contract Manufacturing | |

| Product Price Range | $700/M.T.-$1200/M.T. |

Send your message to us

Grinding Media Ball with High Performance & Competitive Price Used for Metal Mine/Cement Plant/Water Coal Slurry/Power Station/C

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 150,000M.T. m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords