Brushed Aluminum Adhesive Sheets - Grey Color Back Coated Aluminum Sheet Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of PVDF AluminumCoil:

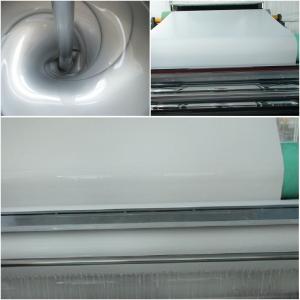

1. Adopting precision rollingcoating technology, our PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PVDF coatedaluminum sheet we produced, there are various colors for your choice.

3. Using infrared heatingtechnology to protect environment from pollution.

4. Our coated aluminum coilhas four-roller coating line, uniform coating thickness and good features.

Raw Material of the PVDFCoated Aluminum Coil:

1. Aluminum Coil: highstrength aluminum with alloy of AA1100 (aluminum alloy is available withAA3003, AA3005, AA5005 according to customer)

2. Surface Paint: PE, PVDF andspecial paints.

Specification of the PVDFCoated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm,505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

Performance and usage

PVDF coated aluminum coils are specially processedthrough the technics of roller coating and baking with precise paints fromBECKER INDUSTRIAL COATINGS in

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm | 0 Grade | ≥HB | no change within 2 hours |

Color of Card

Our PVDF coated aluminum coil is made offluorine carbon resin, pigment, ester solvent after high temperature roastingand baking. The paint of this PVDF coated aluminum coils are solidified to dryfilm with super weather resistance. PVDF coating also can be classified astraditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times forcoating and baking, has good properties of anti-acid, anti-alkali and isdurable in atrocious weather and environment, keeping 15 years no unwontedfading. In view of these facts, we recommend this PVDF coated aluminum coilsare applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clearcoating. It contains nanometer element, which can protect panel from pollution,because nanometer has self-cleaning effect, it is easy to get rid of dust andpollution by raining or water.

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, soit is suggested all panels are placed in one order for same project. And keepsame direction as arrow on protective film when installing to avoid any colordifference by vision.

PE Aluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: Is it possible to recycle aluminum sheets multiple times?

- <p>Yes, aluminum sheets can be recycled again and again. The recycling process for aluminum is highly efficient, and it can be recycled indefinitely without losing any quality. This is due to the fact that aluminum retains its properties even after multiple recycling cycles. Each time aluminum is recycled, it can be melted down and reformed into new products, making it a sustainable and environmentally friendly material.</p>

- Q: What are the different methods of surface printing aluminum sheets?

- Aluminum sheets can be surface printed using various methods, each with its own advantages and applications. Some commonly used techniques include: 1. Screen Printing: This technique involves using a mesh screen with a stencil to transfer ink onto the aluminum sheet. It offers precise printing and vibrant colors, making it suitable for signage, labels, and decorative purposes. 2. Digital Printing: Advancements in technology have made digital printing popular for aluminum sheet printing. It directly prints the design onto the sheet using inkjet technology, offering high detail and a wide range of colors for customized and complex designs. 3. Offset Printing: This versatile method transfers the design from a plate onto a rubber blanket, which is then pressed onto the aluminum sheet. It provides consistent and accurate printing results, often used for packaging, labels, and large-scale printing. 4. Flexographic Printing: This cost-effective method uses flexible relief plates to press the desired design onto flexible materials like aluminum sheets. It is suitable for large-scale production and commonly used for packaging materials and labels. 5. Gravure Printing: Also known as rotogravure printing, this method uses engraved cylinders to transfer ink onto the aluminum sheet. It is known for its high quality and ability to reproduce fine details, often used for high-end packaging, decorative items, and high-resolution images. 6. Embossing: Although not a printing method, embossing is a popular technique for creating raised designs on aluminum sheets. It can be done mechanically or through heat processes, resulting in a three-dimensional effect. Embossed aluminum sheets are used for decorative purposes, architectural applications, or to enhance surface grip. These are just a few of the methods available for surface printing aluminum sheets. The choice of method depends on factors such as design requirements, level of detail, quantity, budget, and intended application.

- Q: 3003H24 alloy aluminum plate refers to what kind of aluminum plate?

- 3003H241, the first to 3 words led by the expression is: manganese as the main alloying elements of aluminum alloy;2, second, 0 words indicate that the aluminum alloy, its impurity limit content without special control;3, third, fourth digit 03 indicates modification alloy, not too much actual connotation;4. H means products that increase strength by working hardening;5, 24 in 2 said the work hardening and incomplete annealing state (i.e. the degree of work hardening than product requirements after incomplete annealing strength is reduced to the specified index products) 4 means O is intermediate state to the 8 state that value.

- Q: What are the properties of anodized aluminum sheets?

- Anodized aluminum sheets have a protective oxide layer that provides increased corrosion resistance, durability, and a decorative finish. They are lightweight, non-toxic, and offer excellent heat and electrical conductivity. Additionally, anodized aluminum sheets are easy to clean, resistant to fading and scratching, and can be dyed in various colors for aesthetic purposes.

- Q: What type of aluminum plate does the traffic sign use? 1100?

- Model is not important, can meet the standard requirements on the line!

- Q: Is it possible to use adhesive instead of fasteners to bond aluminum sheets to a structure?

- <p>Yes, you can use an adhesive to attach aluminum sheets to a structure. However, it's important to choose an adhesive that is specifically designed for bonding aluminum, as not all adhesives provide the necessary strength and durability. Structural adhesives that are compatible with aluminum can offer a strong bond and are often used in applications where a clean, seamless appearance is desired or where fasteners are not suitable. It's crucial to ensure that the adhesive is resistant to the environmental conditions the structure will be exposed to, such as moisture, temperature fluctuations, and UV radiation. Always follow the manufacturer's instructions for surface preparation and application to achieve the best results.</p>

- Q: What is the typical thermal expansion coefficient of aluminum sheets?

- Aluminum sheets generally possess a thermal expansion coefficient of approximately 23.1 x 10^-6 per degree Celsius. Consequently, with each degree Celsius rise in temperature, the length of an aluminum sheet will expand by roughly 23.1 millionths of its initial length. However, it should be acknowledged that this figure might slightly differ based on the particular alloy and processing circumstances of the aluminum sheet.

- Q: A 0.2412 gram sample of aluminum ore was dissolved in a dilute mineral acid. The solution was treated with an excess of sodium oxalate. The resultant aluminum oxalate precipitate was filtered, washed and redissolved in mineral acid, then titrated with 42.12 mL of 0.1098 N KMnO4. Calculate the percent of aluminum in the sample.

- 4Al + 6Na2(C2O4) ---- 2Al2(C2O4)3 + 6KMnO4 ---- 3K2(C2O4) Aluminum oxalate and potassium permanganate are at a 1:3 ratio.... Moles of KMnO4 C = 0.1098 mol/L v = 42.12 ml = 0.04212 L C = n/v n= CV = 0.004624776 mols Therefore moles of aluminum oxylate = 0.001541592 mol = moles of aluminum m= 26.98 g/mol * moles mass of aluminum in oxylate = 0.04159215 g % of initial sample = mass of aluminum / mass of ore = 17.24% aluminum in ore sample Perhaps check my math but the method is for sure correct.

- Q: What are the different types of alloys used in aluminum sheets?

- Aluminum sheets utilize a variety of alloys, each possessing distinct properties and advantages. The following are some commonly employed alloys: 1. The 3003 alloy offers exceptional formability, corrosion resistance, and weldability, making it suitable for general-purpose use. It finds applications in cooking utensils, signage, and chemical equipment. 2. Known for its high strength and good corrosion resistance, the 5052 alloy is frequently utilized in marine and automotive fields. It is also employed in sheet metal fabrication and structural components. 3. The 6061 alloy is highly versatile and finds application in several sectors such as aerospace, automotive, and structural components. It provides excellent strength, machinability, and weldability. 4. Primarily used in aerospace and high-strength applications, the 7075 alloy boasts an exceptional strength-to-weight ratio. It is commonly employed in aircraft fittings, gears, and bike frames. 5. The 2024 alloy, popular in aerospace applications, exhibits a high strength-to-weight ratio and excellent fatigue resistance. It is commonly used for aircraft structures, bolts, and rivets. 6. The 5083 alloy, specifically designed for marine applications, showcases outstanding corrosion resistance and high strength. It is frequently utilized for boat hulls and structural components. These are merely a few instances of the diverse alloys employed in aluminum sheets. Each alloy possesses a unique combination of properties that enable it to excel in specific applications.

Send your message to us

Brushed Aluminum Adhesive Sheets - Grey Color Back Coated Aluminum Sheet Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords