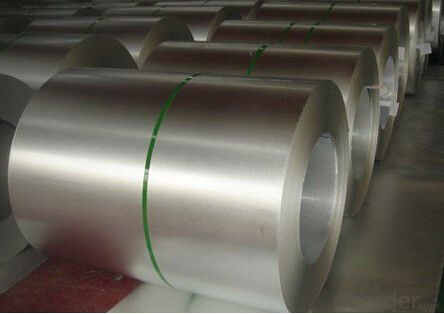

Grade 201 Prime Hot Rolled Cold Rolled Stainless Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Model NO.:201

Type:Stainless Steel Strips

Shape:Round

Grade:200 Series

Certification:ISO, AISI, ASTM, GB, EN, DIN, JIS

Perforated:Not Perforated

Standard:ASTM, AISI, GB, DIN, EN

Technique:Cold Rolled

Surface Treatment:Polished

Width:20-1240mm

Thickness:0.15mm - 2.0mm

Finish:2b, Ba

Export Markets:Global

Additional Info.

Packing:Standard Export Packing

Standard:Grade 201, 430, 410S

Origin:China

HS Code:7220

Production Capacity:30000 Ton Annual

Product Description

201 stainless steel strips or coils:

Cold rolled stainless steel strips or coils

Thickness: 0.15mm to 2.0mm

Width:20mm to 1240 mm

Finish: 2B, BA(two side polishing)

Hot rolled stainless steel strips or coils

Thickness: 2.4mm to 6.0mm

Width:405mm to1520mm

Finish: No.1

Chemical composition:

1) AOD (Low carbon, high nickel) J1 material:

Ni: 1.0-1.5%, Cu:0.8-1.0%, Cr:>13.5%, Mn:9-11%, C:<0.1%

2) AOD (Low carbon, high nickel) J3 material:

Ni: 1.0-1.5%, Cu:0.5-0.8%, Cr:>12%, Mn:9-11%, C:<0.12%

3) Induction (High carbon, low nickel) material:

Ni: 0.6-0.9%, Cu:0.6-0.8%, Cr:>13.0%, Mn:9-11%, C:>0.12%

Application: Making pipes, Utensils, Decoration, Construction, Stamping,Kitchenware, Cookware and so on

Package: standard export packing.

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day

- Q: What are steel coils?

- Steel coils are large, flat sheets of steel that have been rolled into a circular shape. They are commonly used in various industries, including automotive, construction, and manufacturing, for purposes such as making pipes, tubes, and sheet metal products.

- Q: what pokemon are week to steel type pokemon like lucario? help please, and thank you.

- Rock pokemon are weak against steel type moves.

- Q: I expect that I will be questioned about my knowledge in methoding for steel castings, in a interview. I dont know about it. Can someone explain me in simple language and give me some links, like how I can explain methoding for steel castings.....key points...help please...so that i will pass the interview as if I have experience in methoding....thanks

- It is very difficult to define Methoding of Steel castings by one sentence. Actually it encompasses the total casting process. Normally it would mean a) Pattern design i.e. what type of pattern it would be- wooden, metallic, split or full, loose or fitted on a match plate or any other, how will be the parting line. b) Design of the gating system. c) Design of risering i.e. numbers, size and location of risers. d) Design of molding process i.e. sand system to be used, mold box size. But to do justice to the above mentioned activities, you need to consider other parameters of the casting process such as chemical composition, solidification characteristics, pouring temperature, pouring time, knock out time etc. As I said Methoding of Steel castings means designing of the total casting process from inception to final product.

- Q: What are the dimensions of steel coils used in automotive component manufacturing?

- The dimensions of steel coils used in automotive component manufacturing vary depending on the specific application and requirements. However, common dimensions include thicknesses ranging from 0.5mm to 3mm and widths ranging from 600mm to 2000mm.

- Q: How do steel coils contribute to sustainability in construction?

- Several factors contribute to the sustainability of construction when it comes to steel coils. To begin with, steel is an incredibly durable material with a long lifespan. Its use in the construction of structural components like beams, columns, and frames ensures the stability and strength of buildings. This durability translates to reduced maintenance requirements and a longer service life for structures. As a result, the need for frequent repairs or replacements is diminished, leading to a decrease in the overall environmental impact associated with material waste and energy consumption. Moreover, steel is highly recyclable. Steel coils can be easily recycled and reused in new construction projects. The recycling process for steel has a significantly lower environmental impact compared to the production of new steel. By incorporating recycled steel coils into construction projects, the demand for new steel production is reduced, resulting in lower greenhouse gas emissions and a smaller carbon footprint. This approach helps conserve natural resources, reduces the extraction of raw materials, and minimizes energy consumption in steel production. Additionally, steel is an ideal material for off-site prefabrication. This means that steel coils can be manufactured in controlled environments in factories, minimizing construction waste and improving construction efficiency. Prefabricating steel coils reduces on-site material waste and decreases the need for transportation of construction materials. Consequently, this reduces air pollution and energy consumption during construction. Furthermore, steel's high strength-to-weight ratio allows for lighter and more efficient structures. By using steel coils, construction projects can optimize material usage, resulting in reduced material consumption and lessening the overall environmental impact. The lightweight nature of steel coils also facilitates easier transportation, reducing fuel consumption and associated emissions during delivery. In summary, steel coils contribute to the sustainability of construction through their durability, recyclability, prefabrication capabilities, and high strength-to-weight ratio. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce energy consumption, and decrease the environmental impact, ultimately promoting a more sustainable built environment.

- Q: How are steel coils used in the production of steel locks?

- Steel coils are used in the production of steel locks as they are rolled into sheets and then cut into appropriate sizes to form the body and components of the locks. The coils provide a consistent and high-quality raw material that can be easily shaped and transformed into the desired lock designs, ensuring durability and strength in the final product.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- If you want a good quality knife, stay away from Stainless, I would suggest one that is a mix of high and low carbon steel, high carbon holds the edge, but is brittle, low carbon is more malleable, which prevents from breaking when used.

- Q: Hey I just got a mini 14 manufactured in 1980. I also had some .223 Wolf steel cased HP rounds (about 200) that i could shoot throught it, but I was just wondering if its a bad idea to use this steel cased ammo...? Only the casing is steel i believe... and the bullet is copper jacketedthanks for your help

- I have had significant ejection and rechambering problems with Wolf semi-auto handgun ammo. It took forever to clean the fouling that the lacquered ammo generated too. I do not know about the rifle ammo, but I won't tempt fate over cheap rounds again.

- Q: How are steel coils inspected for flatness using optical sensors?

- Steel coils are inspected for flatness using optical sensors by measuring the surface profile of the coil. These sensors use laser or camera technology to scan the coil's surface and detect any deviations from a perfectly flat shape. The collected data is then analyzed to identify any areas that do not meet the required flatness criteria, allowing for necessary adjustments to be made before the steel coils are further processed or shipped.

- Q: How do steel coils contribute to the manufacturing of HVAC systems?

- Steel coils play a crucial role in the manufacturing of HVAC systems. These coils are typically made from high-quality steel, which offers exceptional strength, durability, and heat resistance. One of the main uses of steel coils in HVAC systems is for heat exchangers. Heat exchangers are vital components that facilitate the transfer of heat between two different mediums, usually air and a refrigerant. In an HVAC system, steel coils are used in both the evaporator and condenser coils. The evaporator coil absorbs heat from the air inside a building, while the condenser coil releases heat to the outside environment. These coils are designed with numerous tubes that are coiled and connected with fins. The steel construction of these coils ensures that they can withstand high-pressure environments and resist corrosion, ensuring long-term reliability and efficiency of the HVAC system. Steel coils also contribute to the overall structural integrity of HVAC systems. They are commonly used in the fabrication of ductwork, which is responsible for distributing conditioned air throughout a building. The strength and rigidity of steel coils allow ductwork to maintain its shape and structural integrity under various conditions, including high air pressure and temperature fluctuations. Furthermore, steel coils are often used in the fabrication of HVAC system cabinets and enclosures. These cabinets house various components of the system, such as compressors, fans, and control panels. The robustness of steel coils ensures that the cabinets can withstand external forces, protect the internal components, and provide a secure housing for the entire HVAC system. In summary, steel coils are essential components in the manufacturing of HVAC systems. Their strength, durability, and heat resistance make them ideal for heat exchangers, ductwork, cabinets, and enclosures. By utilizing steel coils, HVAC manufacturers can produce systems that efficiently and effectively regulate temperature, improve indoor air quality, and provide comfort in various residential, commercial, and industrial settings.

Send your message to us

Grade 201 Prime Hot Rolled Cold Rolled Stainless Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords