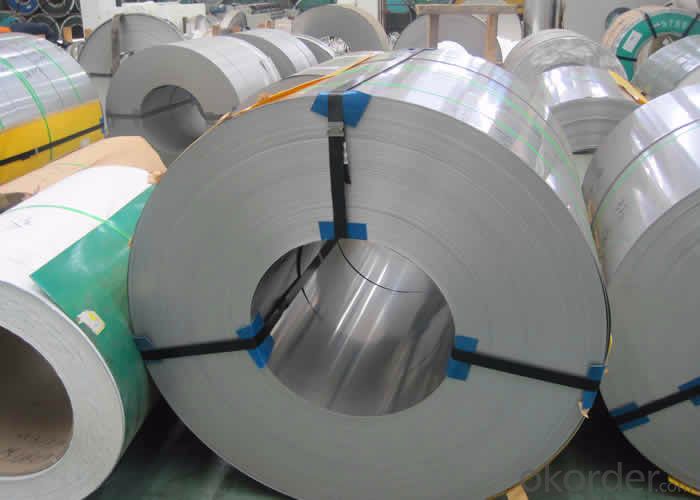

Stainless Steel Coil 201 Hot Rolled Narrow Coil J3

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil

201 Narrow/Wide Strip No.1 Finish

Packaging Detail: For customer's requirement

Delivery Detail: 10-30days

201 Hot Rolled Stainless Steel Coil Specifications

THK:2.3/2.5/3.0/4.0mm

Width:485/510/550/610/1010/1240mm

Face:No.1

201 Hot rolled stainless steel Coil Application

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

201 Hot Stainless Steel Coil Chemical Composition(WT%)

(C):≤0.15, (Si):≤0.75, (Mn):5.5~7.50, (Cr):16.0~18.0, (N):≤0.25, (Ni):3.50~5.50, (P):≤0.060, (S):≤0.030

201 Hot Rolled Stainless Steel Coil

Strength Of Extension:100,000 To 180,000 Psi;

Yield Strength:50,000 To 150,000 Psi

Elongation :55 To 60%;

Modulus Of Elasticity:29,000,000 Psi;

Density :.280lbs/Cubic Inch(7.93g/Cm3)

- Q:What are the limitations of using 111 stainless steel strips?

- There are several limitations associated with using 111 stainless steel strips: 1. Corrosion Resistance: While stainless steel is generally known for its corrosion resistance, 111 stainless steel strips may not have the same level of resistance as other grades. This can make them more susceptible to corrosion in certain environments, such as those with high levels of chloride or sulfur. 2. Strength and Hardness: Compared to other stainless steel grades, 111 stainless steel strips may have lower strength and hardness properties. This can limit their suitability for applications that require high tensile strength or resistance to wear and abrasion. 3. Weldability: Welding 111 stainless steel strips can be challenging due to their higher carbon content. This can result in the formation of carbides during the welding process, leading to reduced weldability and potential brittleness in the heat-affected zone. 4. Magnetic Properties: Unlike some other stainless steel grades, 111 stainless steel strips are generally magnetic. This can limit their use in certain applications where non-magnetic properties are required, such as in electronic devices or sensitive equipment. 5. Availability and Cost: 111 stainless steel strips may be less readily available in the market compared to more common grades. This can make them harder to source and potentially more expensive. 6. Temperature Limitations: 111 stainless steel strips may have limitations when exposed to high temperatures. They may exhibit reduced strength and increased susceptibility to oxidation or scaling, which can restrict their use in high-temperature applications. It is important to consider these limitations when selecting stainless steel strips for specific applications, as they can impact the performance, durability, and cost-effectiveness of the material.

- Q:What's the difference between stainless steel coil and stainless steel plate?

- One is a coil and the other is a strip.

- Q:Can stainless steel strips be used in water treatment applications?

- Yes, stainless steel strips can be used in water treatment applications. Stainless steel is highly resistant to corrosion and can withstand exposure to water, making it an ideal material for use in water treatment processes where the strips may come into contact with water or other liquids. Additionally, stainless steel has hygienic properties, is easy to clean, and has excellent longevity and durability, making it a suitable choice for water treatment applications.

- Q:What are the common uses of stainless steel strips in the petrochemical industry?

- Due to their exceptional qualities and characteristics, stainless steel strips are widely utilized in the petrochemical industry for various applications. In this industry, stainless steel strips find common uses in the following: 1. Heat exchangers: Crucial in petrochemical processes, heat exchangers are often manufactured using stainless steel strips. Their high corrosion resistance ensures the longevity and reliability of the heat exchangers, even in harsh operating conditions. 2. Storage tanks and vessels: Petrochemical plants require storage tanks and vessels to store chemicals and substances. Stainless steel strips are commonly used in constructing these tanks due to their excellent resistance to corrosion, chemical attacks, and high temperatures. 3. Piping systems: Preferred for fabricating piping systems, stainless steel strips provide high strength, corrosion resistance, and the ability to withstand extreme temperatures. This makes them suitable for transporting corrosive and high-pressure fluids. 4. Reactors and pressure vessels: In the petrochemical industry, reactors and pressure vessels are used for various chemical reactions and processes. Stainless steel strips are extensively utilized in constructing these critical equipment due to their durability, resistance to pitting and crevice corrosion, and ability to handle high pressures. 5. Flanges and fittings: Stainless steel strips are commonly employed in producing flanges and fittings used in petrochemical plants. These components require materials that can withstand high-pressure environments and resist corrosion, making stainless steel strips an ideal choice. 6. Instrumentation and control systems: Stainless steel strips are also used in manufacturing instrumentation and control systems in the petrochemical industry. These strips provide excellent dimensional stability, resistance to temperature fluctuations, and resistance to chemical exposure. This ensures the accuracy and reliability of the control systems. Overall, the petrochemical industry extensively relies on stainless steel strips due to their superior corrosion resistance, high strength, heat resistance, and durability. These qualities make them indispensable for critical applications where reliability and longevity are crucial factors.

- Q:What are the common uses of stainless steel strips in the food manufacturing process?

- Due to their unique properties and hygienic nature, stainless steel strips find wide application in the food manufacturing process. Some typical uses of stainless steel strips in this industry include: 1. Conveyor Belts: Food processing plants commonly employ stainless steel strips as conveyor belts. These strips possess corrosion resistance and can withstand high temperatures, making them suitable for transporting food items throughout various production stages. 2. Food Processing Equipment: Stainless steel strips are utilized in the construction of equipment such as mixers, blenders, grinders, and slicers. The strength and durability of these strips ensure that the equipment can withstand the demanding requirements of food processing while maintaining a clean and hygienic surface. 3. Food Storage and Handling: Stainless steel strips are used to fabricate storage containers, shelves, and racks in food manufacturing facilities. The non-reactive nature of stainless steel guarantees that it won't contaminate food products, thereby preserving their quality and safety. 4. Food Packaging: Stainless steel strips are employed in the production of food packaging materials, including cans, trays, and lids. These strips provide robust and durable packaging, safeguarding the food from external contaminants and ensuring its freshness and longevity. 5. Heat Exchangers: The construction of heat exchangers, which play a crucial role in the food manufacturing process, often involves stainless steel strips. Heat exchangers facilitate the heating or cooling of food products, maintaining the desired temperature for processing, pasteurization, or storage. 6. Sanitary Fittings: Stainless steel strips are used to fabricate sanitary fittings such as pipes, valves, and connectors. These fittings are vital in maintaining a hygienic environment in food processing facilities, as stainless steel is easy to clean, resistant to bacterial growth, and does not contaminate food products. Overall, the widespread usage of stainless steel strips in the food manufacturing process revolves around their corrosion resistance, durability, cleanliness, and ability to preserve food quality and safety.

- Q:What is stainless steel strip?

- Stainless steel strip is a narrow and thin flat metal product made from stainless steel, a corrosion-resistant alloy that contains a high percentage of chromium. It is typically used in various applications such as automotive, construction, and manufacturing, due to its durability, strength, and resistance to rust and staining.

- Q:Can stainless steel strips be bent or shaped?

- Stainless steel strips possess the ability to be bent or shaped. This type of material is known for its high malleability, enabling it to be effortlessly transformed into different forms and configurations. By utilizing the appropriate tools and techniques, stainless steel strips can be flexed, curved, or molded into the desired shape. The bending or shaping process typically entails the utilization of specialized machinery such as press brakes, rollers, or mandrels, which exert force on the stainless steel strip to achieve the intended configuration. Moreover, the thickness and tempering of the stainless steel strip play a role in determining its flexibility and ability to assume different shapes. All in all, stainless steel strips offer a remarkable level of versatility and can be easily manipulated to suit various applications and designs.

- Q:Can stainless steel strips be used in chemical storage applications?

- Indeed, chemical storage applications can make use of stainless steel strips. With its exceptional resistance to corrosion and ability to endure exposure to a wide range of chemicals, stainless steel emerges as an outstanding option for secure chemical storage. Moreover, its durability, ease of cleaning, and impressive strength-to-weight ratio render it fitting for storing and transporting chemicals across diverse environments. The non-reactive characteristic of stainless steel guarantees the utmost purity of the stored chemicals, while its capability to withstand high temperatures further solidifies its appropriateness for chemical storage purposes.

- Q:Can stainless steel strips be used in the production of chemical tanks?

- Yes, stainless steel strips can be used in the production of chemical tanks. Stainless steel is highly resistant to corrosion and chemical reactions, making it a suitable material for storing and transporting various chemicals. The durability and strength of stainless steel strips make them ideal for constructing chemical tanks that require long-term reliability and safety.

- Q:Can stainless steel strips be used in the oil refinery equipment?

- Yes, stainless steel strips can be used in oil refinery equipment. Stainless steel is highly resistant to corrosion and high temperatures, making it suitable for use in the harsh conditions of an oil refinery. It has excellent strength and durability, which allows it to withstand the corrosive and abrasive nature of oil refining processes. Additionally, stainless steel strips can be easily formed and fabricated into various shapes and sizes required for oil refinery equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil 201 Hot Rolled Narrow Coil J3

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 400 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords