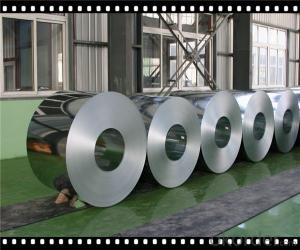

good quality prepainted steel coil for construction of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,DIN,GB,JIS | Grade: | cold rolled,first grade | Thickness: | 0.14-3.0,0.14mm-1.6mm |

| Place of Origin: | Jiangsu China (Mainland) | Brand Name: | cnbm | Model Number: | prepainted steel coil |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Width: | 600-1500,600-1250mm | Length: | coil | color: | According to Ral color card or sample |

| other: | emboss, wood gain, film cover | coil ID: | 508mm, 610mm | zinc caoted: | 60g-275g |

| painted thickness: | 8-75um | Layers of the coating: | 2/2, 2/1, 1/1 | Product Name: | prepainted steel coil |

Packaging & Delivery

| Packaging Detail: | prepainted steel coil export packing |

| Delivery Detail: | 20 days after prepayment |

Specifications

prepainted steel coil

prepainted galvanized steek thickness 0.14mm-1.6mm, width 600mm-1500

prepainted steel coil

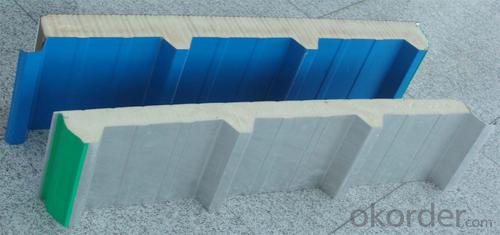

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets. The structure of prepainted steel includes finished coating, primer coating, chemical conversion coating metallic coating and cold-rolled steel. The prepainted steel sheets are mainly provided for various commercial purposes covering architectural construction, electrical household appliances, transportation, etc.

Type of coating structure

2/1: Coat the top surface of the steel sheet twice, coat the lower surface once, and bake the sheet twice.

2/2: Coat the top/lower surface twice and bake twice.

Pre painted Hot dip galvanized steel coil thickness 0.14mm-1.6mm, width 600mm-1500 color coated steel Coil

Specifications:

Base Metal | Hot dipped galvanized steel | DX51D+Z | Normal use |

DX52D+Z | For drawing | ||

DX53D+Z | For deep drawing | ||

S280GD+Z | Structure | ||

S350GD+Z | Structure | ||

S550GD+Z | For high-strength structure | ||

Hot dipped galvalume steel | DX51D+AZ | Normal use | |

DX52D+AZ | For drawing | ||

DX53D+AZ | For deep drawing | ||

S280GD+AZ | Structure | ||

S350GD+AZ | Structure | ||

S550GD+AZ | For high-strength structure | ||

Thickness | 0.14mm-1.6mm | ||

Width | 600mm-1500mm | ||

Coil ID | 508mm, 610mm | ||

Layers of the coating | 2/2(2 layers of top coating/2 layers of bottom coating); 2/1(2 layers of the top coating, 1 layer of bottom coating); 1/1(single layer of top coating/ single layer) | ||

Color | According to customers’ request | ||

Coated | ZN60-ZN275 or AZ60-AZ180 | ||

Paint | PE, HDP, SMP, HPC, PVDM | ||

Thickness of the coating | 25um-75um | ||

Surface | Film coverd | ||

grade | CGCC | Normal use |

CGCD 1 | For drawing | |

CGCD 2 | For deep drawing | |

CGC 440 | Structure | |

CGC 490 | Structure | |

CGC 570 | For high-strength structure | |

Thickness | 0.14mm-1.6mm | |

Width | 600mm-1500mm | |

Coil ID | 508mm, 610mm | |

Layers of the coating | 2/2(2 layers of top coating/2 layers of bottom coating); 2/1(2 layers of the top coating, 1 layer of bottom coating); 1/1(single layer of top coating/ single layer) | |

Color | According to customers’ request | |

Paint | PE, HDP, SMP, HPC, PVDM | |

Thickness of the coating | 25um-75um | |

Surface | Film coverd | |

Applications:

construction | workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door |

door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter | |

Electrical appliance | refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker |

Furniture | central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf |

Carrying trade | exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board |

other | writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment |

- Q: what is the difference between METAL and STEEL?

- A metal is a chemical element that is a good conductor of both electricity and heat and forms cations and ionic bonds with non-metals. Steel is a compound made from Iron and Carbon. Ratios of 0.2% and 2.1% by weight (information by wikipedia)

- Q: if steel is heated from room temperature (20c) to (500c) what would be the change in density?coefficient for linear expansion of steel 12x10^-6 k density of steel 7800 kg

- First you have to convert the coefficient of linear expansion to a coefficient of volumetric expansion. Multiply the coefficient of linear expansion by 3: Coefficient of expansion of steel,β:12E-6/°K x 3 = 36E-6/°K Difference in temperature: 480°K ΔV = VoβΔT ΔV = Vo x (0.000036) x 480 ΔV = 1m? x 0.017 ΔV = 0.017m? Originally, the steel was at 7800 kg/m? Now, the steel was at 7800 kg/ 1.017m?, or 7670 kg/m? Change in density = 7670 - 7800 = -130kg/m?

- Q: What are the different types of steel coil processing equipment?

- There are several different types of steel coil processing equipment, including coil slitting machines, coil cut-to-length machines, coil leveling machines, and coil edge trimming machines. Each of these machines serves a specific purpose in the steel coil processing industry, helping to efficiently and accurately cut, shape, and prepare steel coils for various applications.

- Q: I'm buying a new set of steel plugs.I've heard things about streched ears and cold weather not being to good. do you think it would be bad to be wearing steal plugs?

- Personally, okorder They are spot on for sizing, they do customs, and amazing quality like i have never seen before and I have been through a lot of plugs. Hope this helps :)

- Q: i know stainless steel swords are decoration, what metal is ok for a sword that is usable

- carbon steel will hold a good edge, but will corrode easily. The nicest blades I have seen are made from damascus steel (repeatedly folded over and over). It makes a blade which is good and flexible sideways, but more rigid in the cutting direction, and it holds an edge extremely well. It also looks awesome due to the grain effect from the folds, but is very expensive.

- Q: What does INOX Steel means?I have been looking up the meaning but cannot find it... please help...

- Inox Steel

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps including uncoiling, leveling, cutting, shaping, and surface treatment. The uncoiling process involves unwinding the steel coil to create a flat sheet. Next, leveling machines remove any unevenness in the sheet's surface. Then, the sheet is cut into desired lengths or shapes using cutting machines. Shaping processes such as bending, rolling, or stamping are performed to achieve the desired product form. Finally, surface treatment techniques like galvanizing, painting, or coating are applied to enhance the product's durability and appearance.

- Q: I know there is soft steel and sturdier steel they use in products. The sturdier often used for equipment that requires more durability when in operation.

- It kind of depends on the application. It can be anywhere from simple to very difficult depending on what exactly you are talking about. Hardening a small piece of carbon tool steel for a chisel or punch consists of simply heating it till its red hot and then quenching it in water. This is done after the tool is formed. Hardening also means making the steel brittle, so it must be tempered after hardening to make it hard and strong. Hardening large or huge pieces like that used for equipment is done at the foundry, where they have equipment to do such a job.

- Q: Why can't the coil weight be too low?

- And may make the level stacked steel coil collapse, rolling, produce production safety accidents.

- Q: How are steel coils inspected for uniformity?

- Steel coils are inspected for uniformity through a series of visual and mechanical tests. Firstly, the external appearance of the coil is examined to ensure it is free from any visible defects such as dents, scratches, or rust. This is important as it ensures the coil's overall integrity and prevents potential issues during further processing. Next, the thickness of the coil is measured at various points using non-destructive testing techniques like ultrasonic or magnetic particle inspection. This helps identify any variations in thickness, which could affect the coil's overall quality and performance. Additionally, the width of the coil is measured using precision instruments to check for any deviations from the required specifications. This ensures that the coil is within the desired width range, which is crucial for compatibility with downstream processes and applications. Furthermore, the weight of the coil is measured to verify if it falls within the specified range. This is typically done using weighing scales or load cells, ensuring that the weight is consistent and meets the required standards. In terms of internal inspection, steel coils are sometimes subjected to eddy current testing, a non-destructive method that detects surface and near-surface defects. This technique uses electromagnetic induction to identify any irregularities in the metal, enabling the identification of defects such as cracks, voids, or inclusions. Overall, a combination of visual inspections, thickness measurements, width checks, weight verification, and internal testing methods ensures that steel coils are thoroughly inspected for uniformity. These rigorous inspection processes help guarantee the quality and reliability of the coils, allowing them to meet the industry standards and customer requirements.

Send your message to us

good quality prepainted steel coil for construction of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords