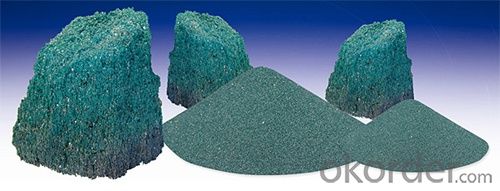

Raw Materials for Refractory:Good Quality Metallurgical Grade Black Silicon Carbide for Metal Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | CF180# 240# 320# 800# 1200# |

| Material: | SIC | Usage: | Lapping, Polishing,Blasting, Refractories | Abrasive Grain Sizes: | 46#..1200#...2000#..2500# |

| color: | black and green | hardness: | 9.15 mosh | melting point: | 2250 |

Packaging & Delivery

| Packaging Details: | bags, cartons |

| Delivery Detail: | 15-20 days |

Specifications

silicon carbide Size Available:

F10-F220,F240-F1200

Other special size could be supplied as required.

| 1.used for made abrasive products 2.professional manufacture 3.prompt reply-within 24hours 4.prompt delivery-within 15days. | |||

| Grit | SiC | F.C. | Fe2O3 |

| F12-F90 | 98.50%min | 0.20%max | 0.60%max |

| F100-F150 | 98.00%min | 0.30%max | 0.80%max |

| F180-F220 | 97.00%min | 0.30%max | 1.20%max |

| F230-F400 | 96.00%min | 0.40%max | 1.20%max |

| F500-F800 | 95.00%min | 0.40%max | 1.20%max |

| F1000-F1200 | 93.00%min | 0.50%max | 1.20%max |

| P12-P90 | 98.50%min | 0.20%max | 0.60%max |

| P100-P150 | 98.00%min | 0.30%max | 0.80%max |

| P180-P220 | 97.00%min | 0.30%max | 1.20%max |

| P230-P500 | 96.00%min | 0.40%max | 1.20%max |

| P600-P15000 | 95.00%min | 0.30%max | 1.20%max |

| P2000-P2500 | 93.00%min | 0.50%max | 1.20%max |

| Black Silicon Carbide is brittle and sharp and has electrical and heat conductivity in some degree. Aplications : Black Silicon Carbide is suitable for make grinding wheels, cutting wheels, mounted wheels, oil stone, abrasive media, and also suitable for surface grinding, lapping or polishing. The abrasive products made of it are suitable for working on Cast Iron, Non-ferrous Metal, Rock, Leather, Rubber, Wood, Ceramic, etc. Black Silicon Carbide is also broadly used as high-grade refractory material and metallurgical additive. | |||

- Q: What is the strength of high strength refractory material?

- Hefei Jiule decoration is answering your question: Use corundum as aggregate, high alumina cement as binder, mixed with a number of additives prepared, with high strength, and a hydraulic refractory casting material used in hot furnace lining at high temperature.

- Q: What is the fire endurance of ceramsite concrete blocks?

- The heat conductivity coefficient of grade 800 hollow building blocks in ceramsite concrete is 0.23 and fire endurance is 4h. Ceramsite concrete has strong construction adaptability. It can not only compound concrete material with different unit weight and strength(It changes with the structure of thermal insulation or bearing structure) according to the different purposes and functions of buildings, but also is easy to construct. It is suitable for industrial production of a variety of construction methods. It can not only make all types of components(board, block, girder, column, etc) by using production process, but also can use mechanization construction of cast-in-place. The strong adaptability of construction of ceramsite concrete is not comparable to any other lightweight building materials(such as air-entrapping, etc.).

- Q: Which industry does refractory belong to?

- It belongs to decoration industry.

- Q: What level is the rock wool board fireproofing material ?

- The fire rating classification is a provision for all insulation materials, rather than to separately divide rock wool. Determine the value of the material fire rating according to the relevant test items of 8624. As the rock wool is made from basalt fusion, so it is the level A non-combustible material.

- Q: What 's the highest temperature can magnesium plate glass resist ?

- You just need a fire-resistance board thicker than 10 mm ,remember to add more perlite as filler during production , 12 mm plate is 80 yuan.

- Q: can slag tailings be used to be the base materials of refractory materials ?

- the rest of it can be used as refractory additives. the scale currently used clay bricks to make high-temperature liquid. It is easy to produce large amounts of liquid because of the high iron content, instead of its refractoriness. But it can be used as refractory minaralizer.

- Q: how to classify the fireproofing material levels A1 A2 B1?

- their classification is shown specifically in Fireproof? Specification of Building Interior Decoration?Design GB 50222-95 appendix A, flammability,inflammability materials, flame retardency, noninflammability: combustion performance of A, B3, B2, B1 materials are divided into

- Q: Could you tell me how does fire protection standard of decorative material is divided?

- Divided by plate material: structure material, base layel materials and fabric; Divided by fire protecrtion type: easy to burn, difficult to burn, flame retardant, incombustible material. Material has no fire rating, only the different from the time of combustion limit. Building fire protection. Building fire protection is the fire prevention measures of buildings. In the architectural design, fire protection measures should be taken to prevent fires and reduce fire hazards to life and property. Building fire prevention measures includs prophylaxis before the fire and measures during the fires. The former is mainly to determine the fire resistance rating and fire-proof structure, control fuel quantity and space easy to fire site; The latter mainly for fire partition, setting of evacuation and smoke, fire-fighting equipment, etc. In ancient China, flammable wood are usually taken as a building material, which has accumulated many experiences for the building fire protection .

- Q: who knows the technology of fireproofing material?

- 1, dealing mould, scrape and clean the thick liquid on the surface of mould with tin-coated steel scraper blade or plaster tool. 2, adjust laminator, according to the thickness of fireproof?panel, adjust each roller, keep them parallel. 3, ingredient, according to the requirements of recipe, stir the raw materials uniform with agitator. (usually we should add bittern firstly, stir it with modifying agent for 5 minutes, then add filler and stir for 2-3 minutes, finally add grogs and stir it to uniform) note: the stirring speed should be kept in 60-80 r/min. 4, place the cloth, place a layer of non-woven fabric and two layers of glass fiber fabric (mechanical spread fabric). 5, flitch, place the materials after compounding and stirring into stop gauge of laminator, then you can start up and produce continuously, it's finished product after finishing. note: the distance between two templates is 2-4mm.

- Q: How to classify fire resistance rating of brick-concrete structure?

- In order to ensure the safety of the building, the fire protection measures must be taken to make it have a certain degree of fire resistance, even if there is a fire, it will not cause too much damage. According to the national conditions of our country, and in the light of other countries standards, < high-rise civil building fire protection design specification > defines fireproof rank of high-rise civil buildings into level one and two; < code for fire protection design of buildings > divides the rank into level one, two, three, four, level one is the highest level, level four is the lowest. Besides that the minimum fire resistance of the building component is specified, buildings of fire resistance rating also specified requirements for combustion performance. Because the component with the same fire resistance limit is different, it is different in the fire.According to our country national standard < building design fire protection code >, the fire resistance rating of the building is divided into four levels. The fire resistance of a building is determined by the combustion performance and fire resistance of building components (such as beams, columns, floors, walls, etc.). Generally speaking, the fire resistance building of level one is a mixed structure of reinforced concrete structure or a mixture of brick wall and steel concrete structure; the fire resistance building of level two is a mixed structure of steel truss structure, reinforced concrete column and brick wall; the fire resistance building of level three is brick-wood structure made of wood roof and brick wall; the fire resistance building of level four is combustible structure which is composed of wood roof and non-combustible wall.

Send your message to us

Raw Materials for Refractory:Good Quality Metallurgical Grade Black Silicon Carbide for Metal Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords